Quality prediction method based on error propagation network and boosting tree algorithm

An error transmission network and quality prediction technology, which is applied to instruments, comprehensive factory control, control/regulation systems, etc., can solve problems such as low prediction accuracy, complex optimization process, and limited prediction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0106] The present invention will be described in further detail below in conjunction with the accompanying drawings.

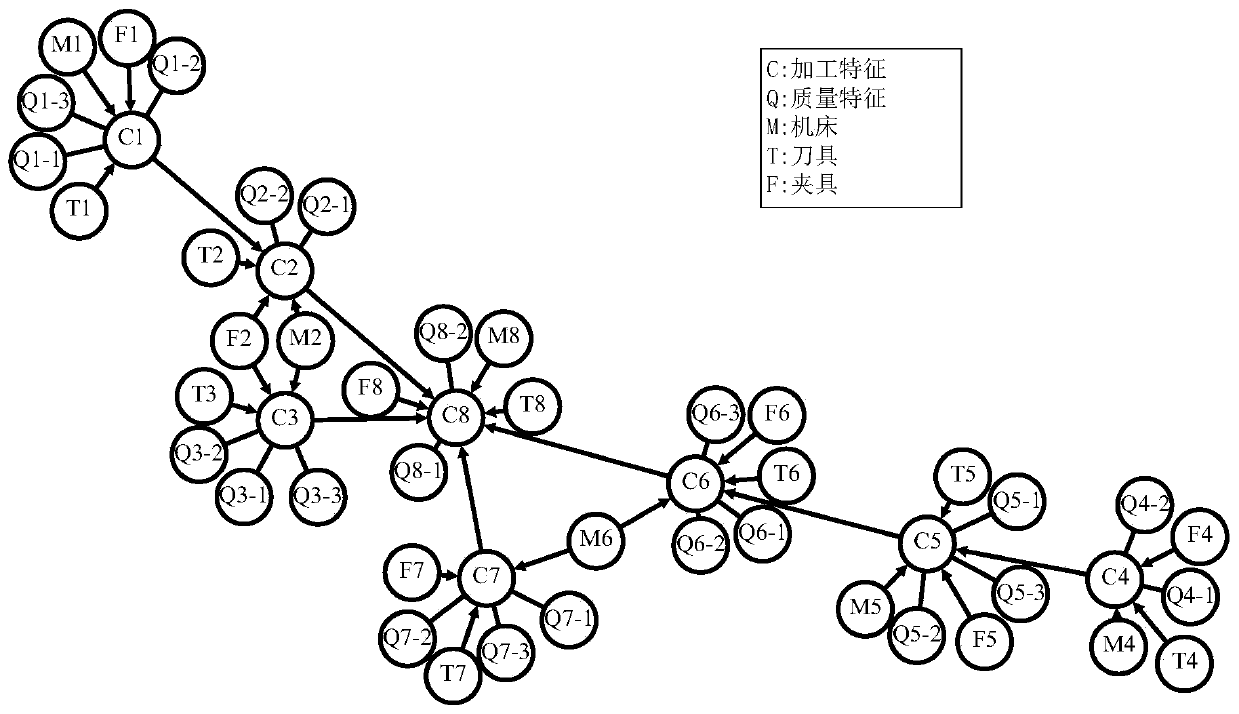

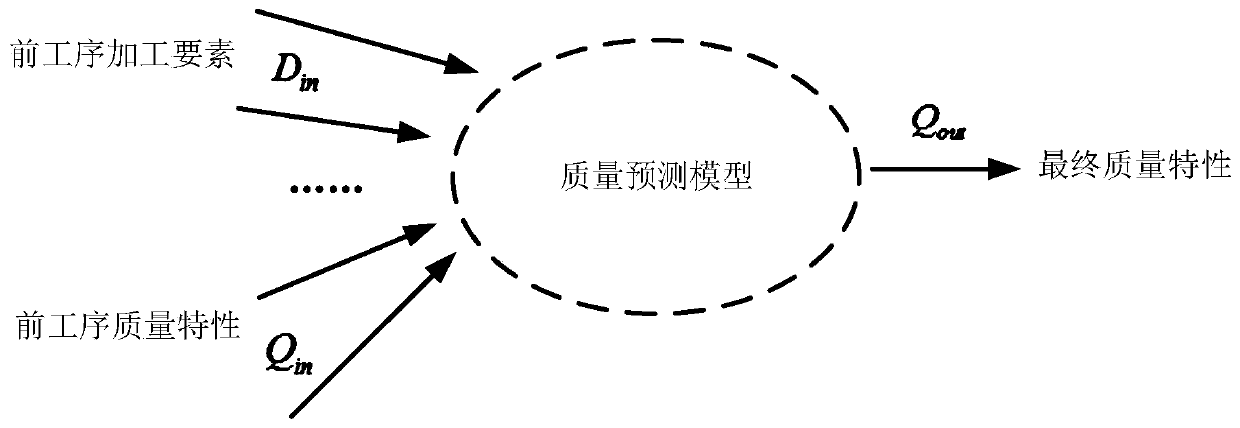

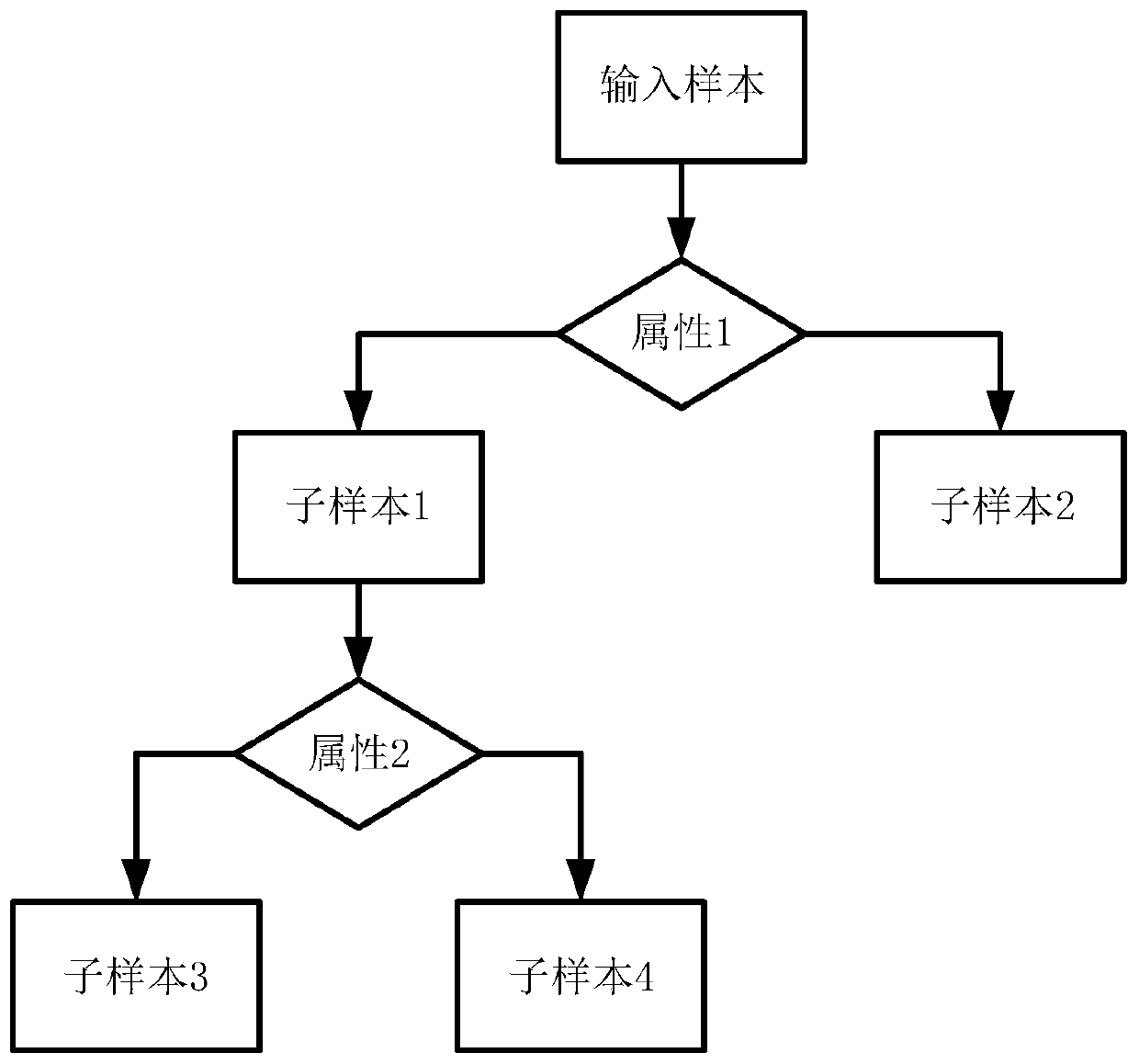

[0107] see Figure 1 to Figure 5 , the processing quality prediction method in the design of the present invention is a new method based on the quality prediction proposed by the digital processing workshop. With the development of detection technology, the establishment of digital workshops is becoming more and more popular in manufacturing enterprises. A large amount of data closely related to the production process is stored in the enterprise's MES and ERP. The quality prediction method based on intelligent algorithms can simulate the internal error flow of the production process. , The complex process of transmission, mining the actual production rules hidden in the data, has good practical value and development prospects.

[0108] Specifically, a quality prediction method based on an error transfer network and a boosted tree algorithm provided by the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com