Method for prolonging service life of synchronizer of gearbox of commercial vehicle

A synchronizer and gearbox technology, which is applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of synchronizer fatigue damage, synchronizer impact, affecting service life, etc., and prolong service life , small changes, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

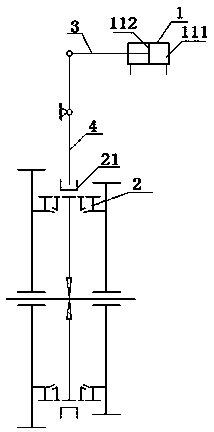

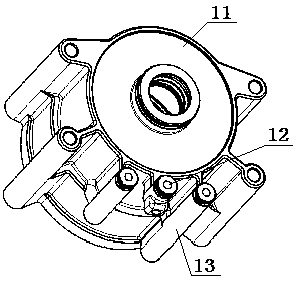

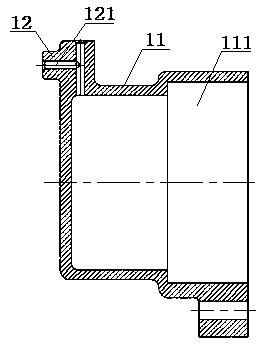

[0037] see Figure 1 to Figure 4 , a method for prolonging the service life of a commercial vehicle gearbox synchronizer, the method is aimed at a shift cylinder with a synchronizer, including a shift cylinder 1, a synchronizer 2 matched with the shift cylinder 1, the shift cylinder 1 Including the shift cylinder body 11 and the No. 1 intake pipe 12 and No. 2 intake pipe 13 provided outside, the inner cavity 111 of the shift cylinder body 11 is provided with a cylinder piston 112, and one side of the cylinder piston 112 passes through The piston rod 3 is connected to one end of the shift fork 4, and the outer wall of the other end of the shift fork 4 is inserted into the inner wall of the gear sleeve 21 of the synchronizer 2. The No. 1 intake pipe 12 and the No. 2 intake pipe 13 The interior of No. 1 air intake pipe 121 and No. 2 air intake pipe 131 are arranged respectively, and the two ends of the No. 1 air intake pipe 121 and No. 2 air intake pipe 131 communicate with the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com