Concrete wall surface dry hanging stone structure and construction method thereof

A technology for dry hanging stone and concrete, which is applied in building construction, building material processing, covering/lining, etc., can solve the problems of small number of right-angle plates and increase the overall stone cost, avoiding processing and manufacturing, and saving costs. , The effect of preventing rain leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

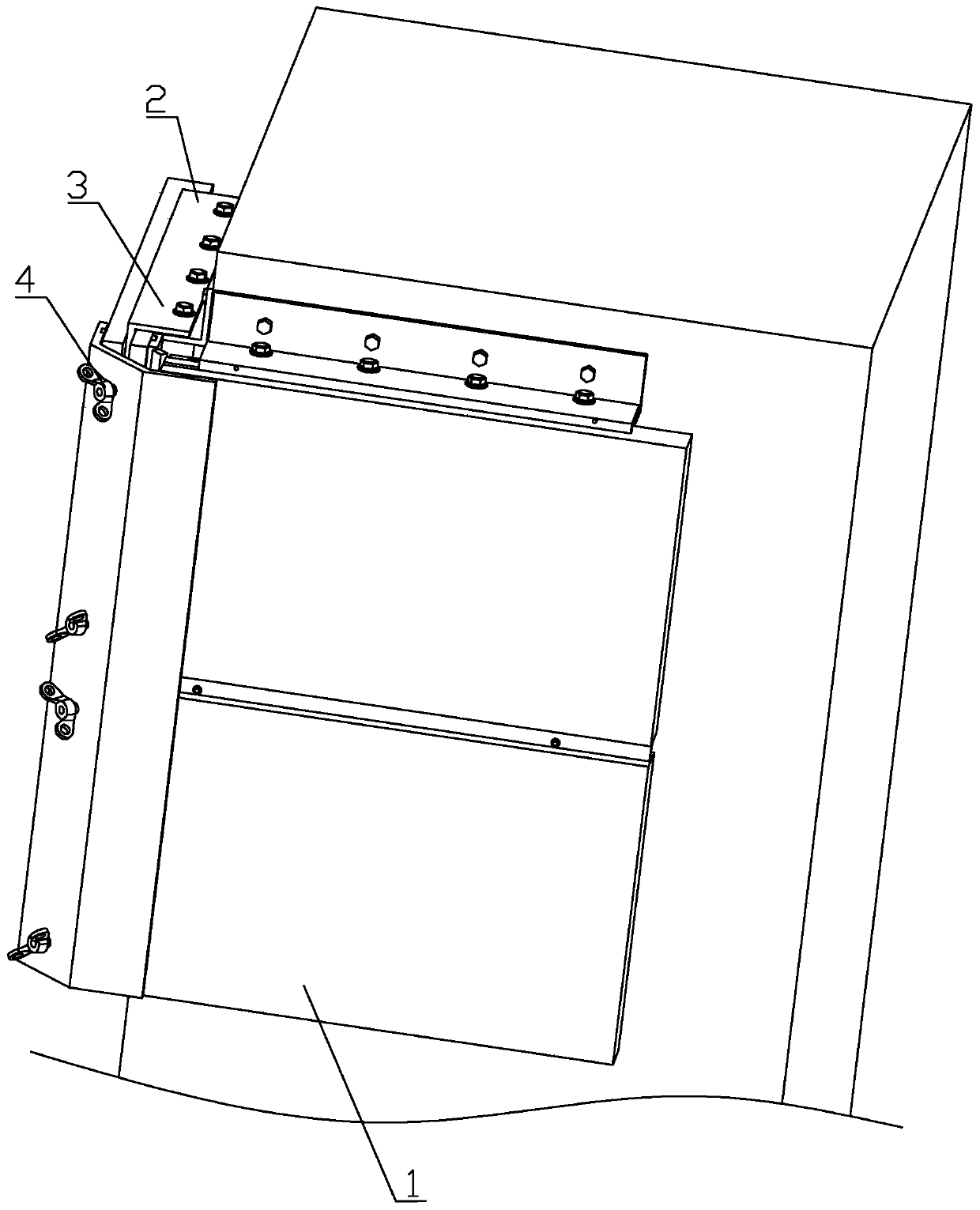

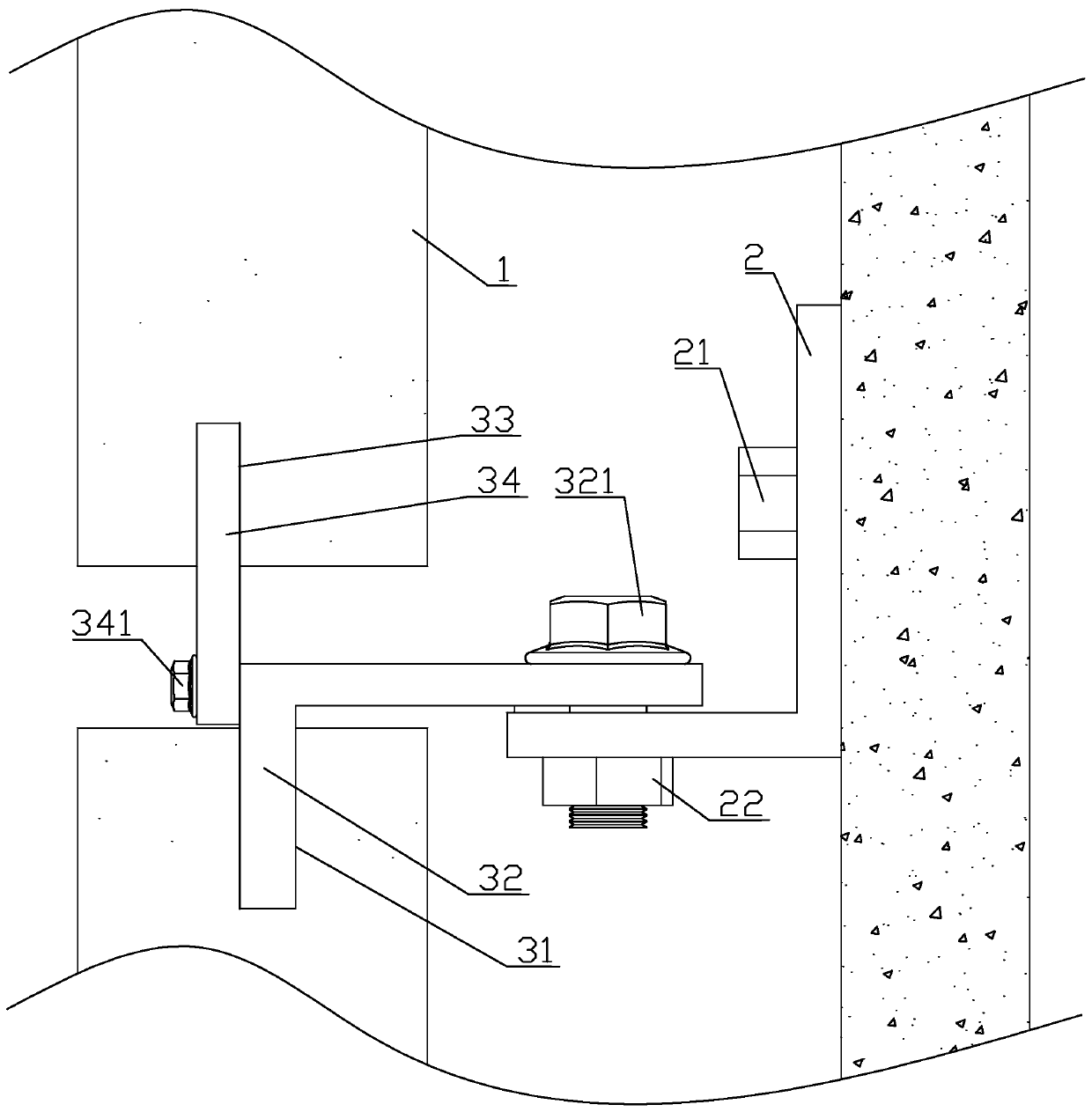

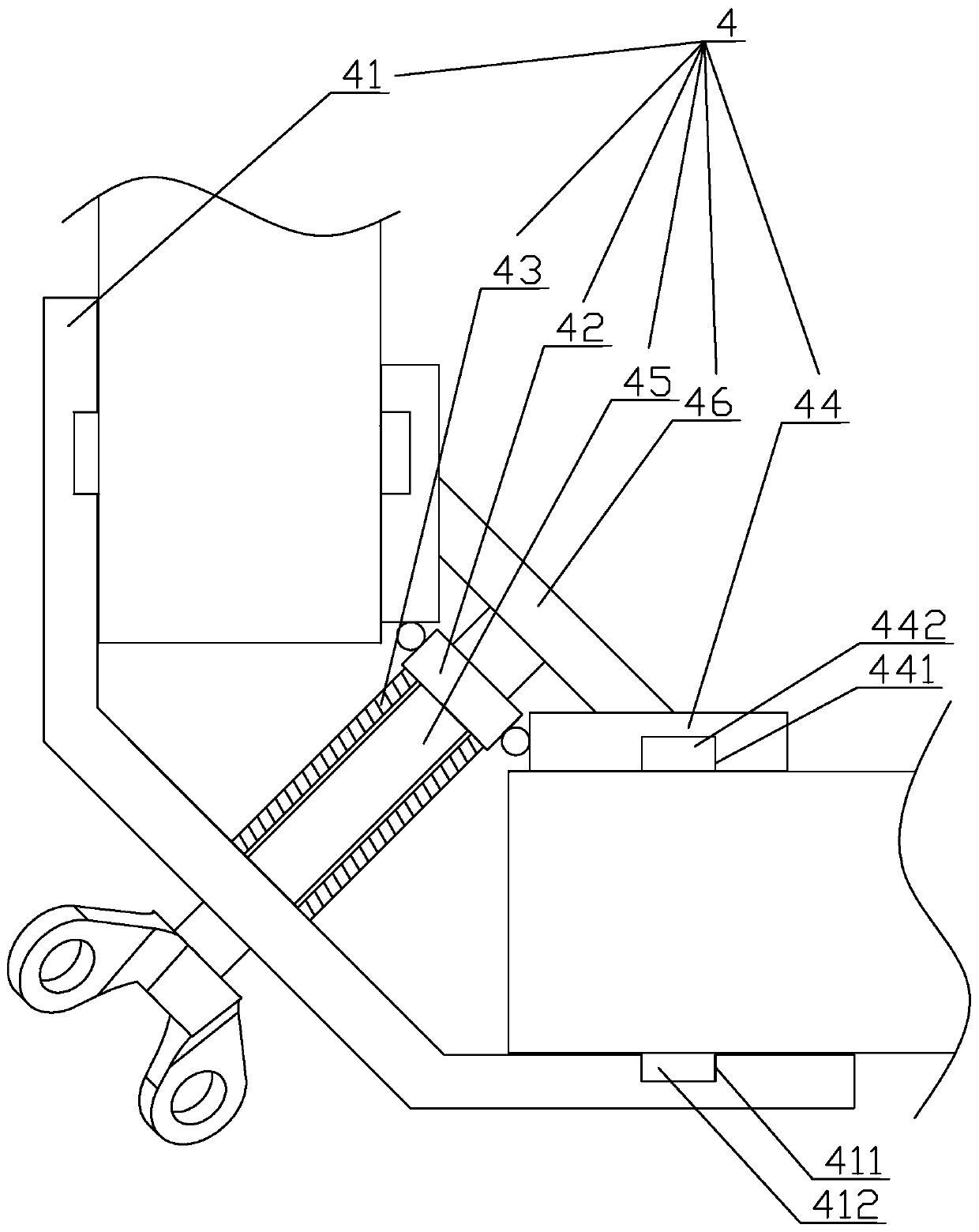

[0040] like figure 1 As shown, a dry-hanging stone structure on a concrete wall includes a stone plate 1 , an installation angle steel 2 , an installation part 3 and a corner connection part 4 . The stone slab is a rectangular plate structure made of cut stone, which is vertically placed outside the concrete wall of the building, and covered with the concrete wall. combine figure 2 As shown, the installation angle steel 2 is a strip structure with a right-angled section, its surface is galvanized, and its length direction is parallel to the concrete wall. The installation angle steel 2 is provided with expansion bolts 21, and the expansion bolts 21 extend into the concrete wall through the side wall of the installation angle steel 2 away from the concrete wall and are fixed with the concrete wall, so that the installation angle steel 2 is fixed on the conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com