Integrated expansion joint system

An expansion joint and one-piece technology, applied to building components, building insulation materials, walls, etc., can solve problems such as non-waterproof, and achieve the effect of easy installation and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

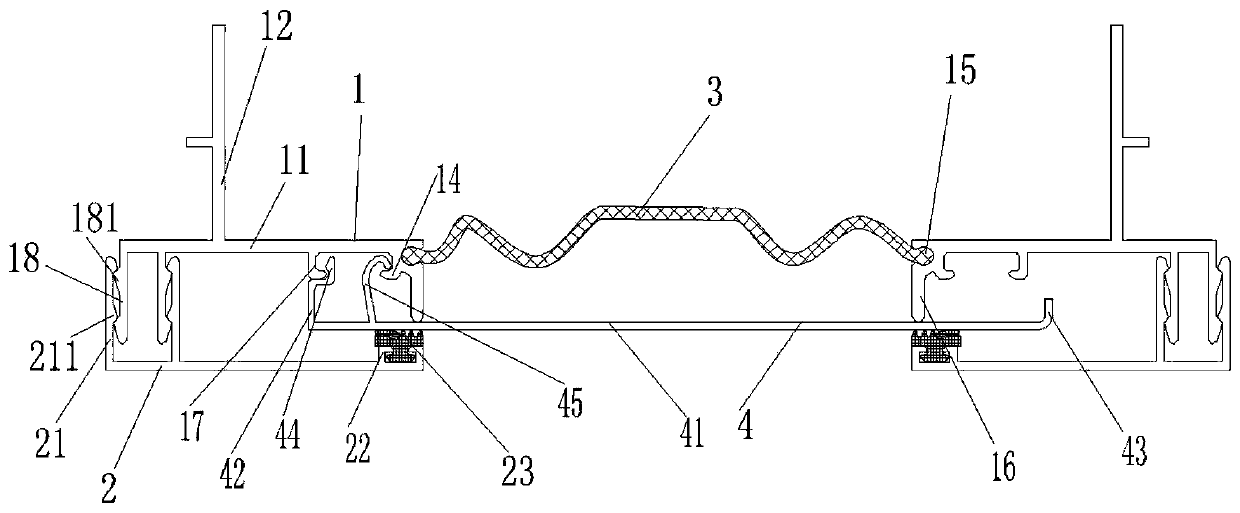

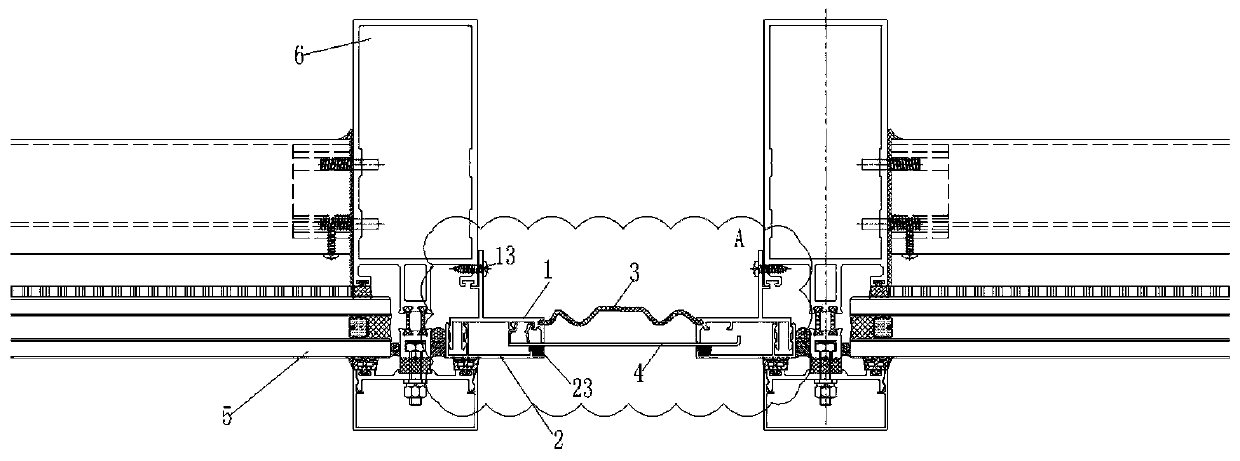

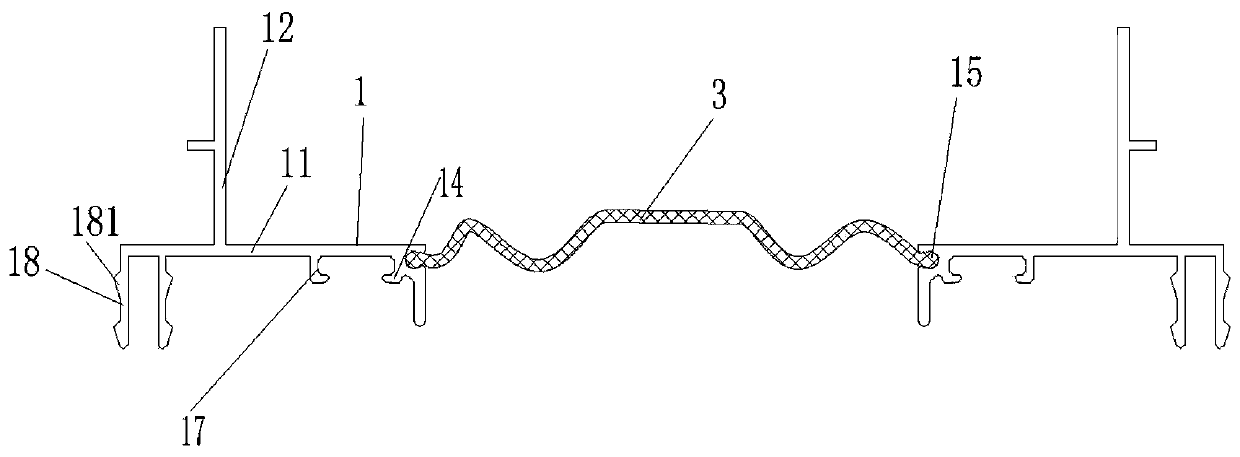

[0022] Such as Figure 1-Figure 3 As shown, an integrated expansion joint system includes two expansion joint bases 1, two expansion joint covers 2, organ panels 3 and aluminum alloy profiles 4, two expansion joint bases 1 and two expansion joint covers The plates 2 are arranged on both sides of the aluminum alloy profile 4 in one-to-one correspondence and symmetrically;

[0023] The two expansion joint bases 1 include a base plate 11 and a connecting plate 12 vertically connected to its upper surface. The connecting plate 12 is provided with a fixing screw hole 13 for connecting with the column 6 of the tempered glass 5;

[0024] Two first L-shaped clips 14 with opposite openings are provided on the bottom of the opposite side of the two substrates 11, and the opposite sides of the two L-shaped clips 21 are provided with notches matching both sides of the organ board 3 15. The two ends of the organ plate 3 are fixedly clamped in the two notches 15, and the organ plate 3 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com