Automatic leveling device and leveling method for fused deposition additive manufacturing

An automatic leveling and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of inability to achieve accuracy and efficiency, improve printing accuracy and printing efficiency, eliminate differences in printing quality, and realize the effect of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

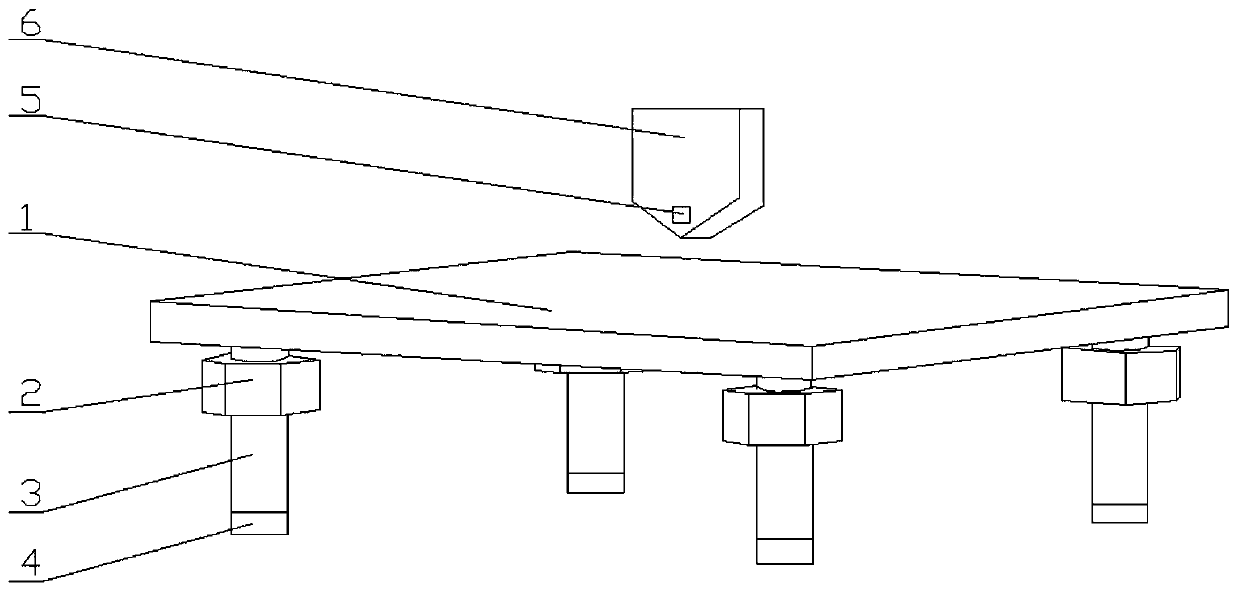

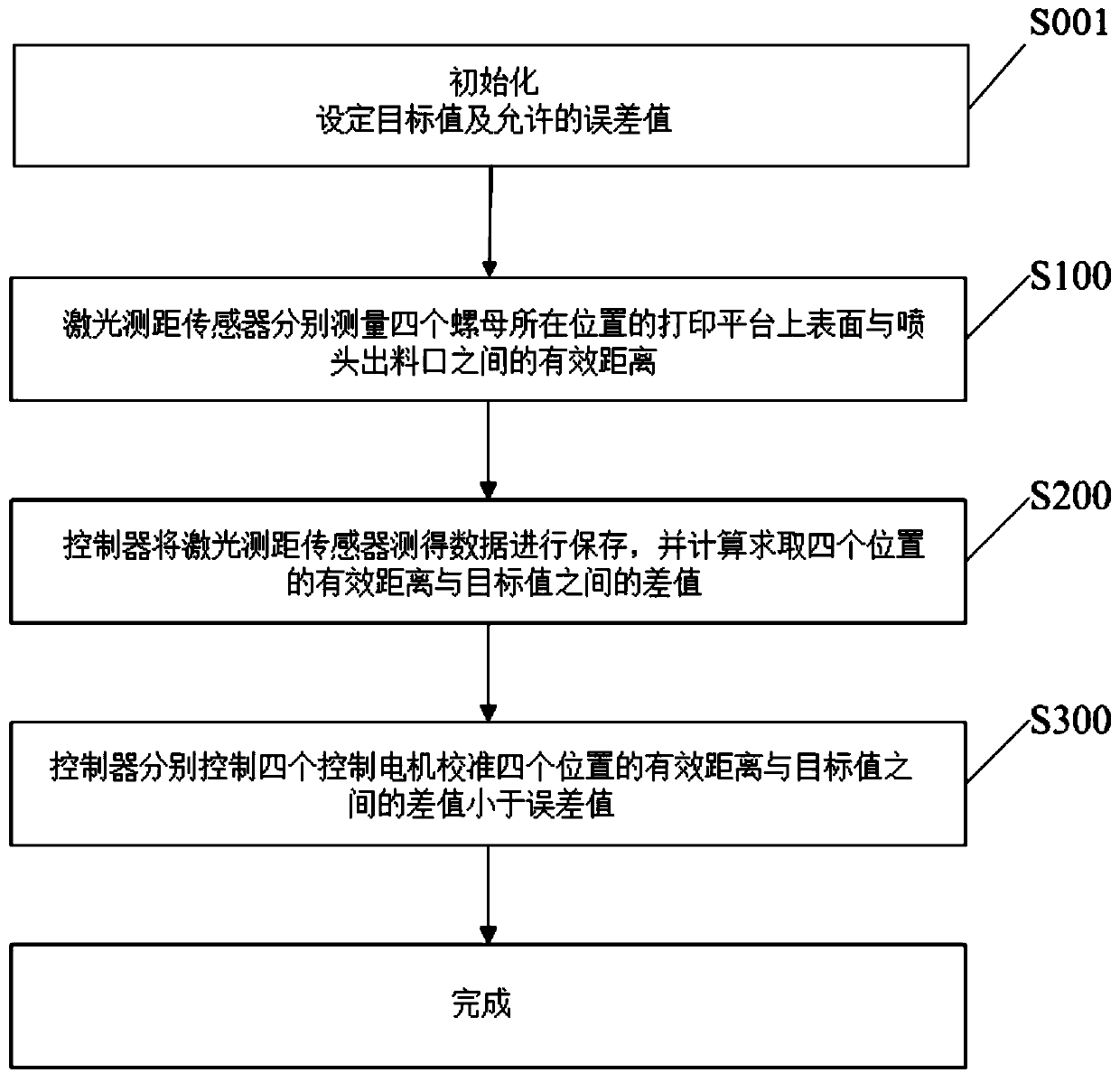

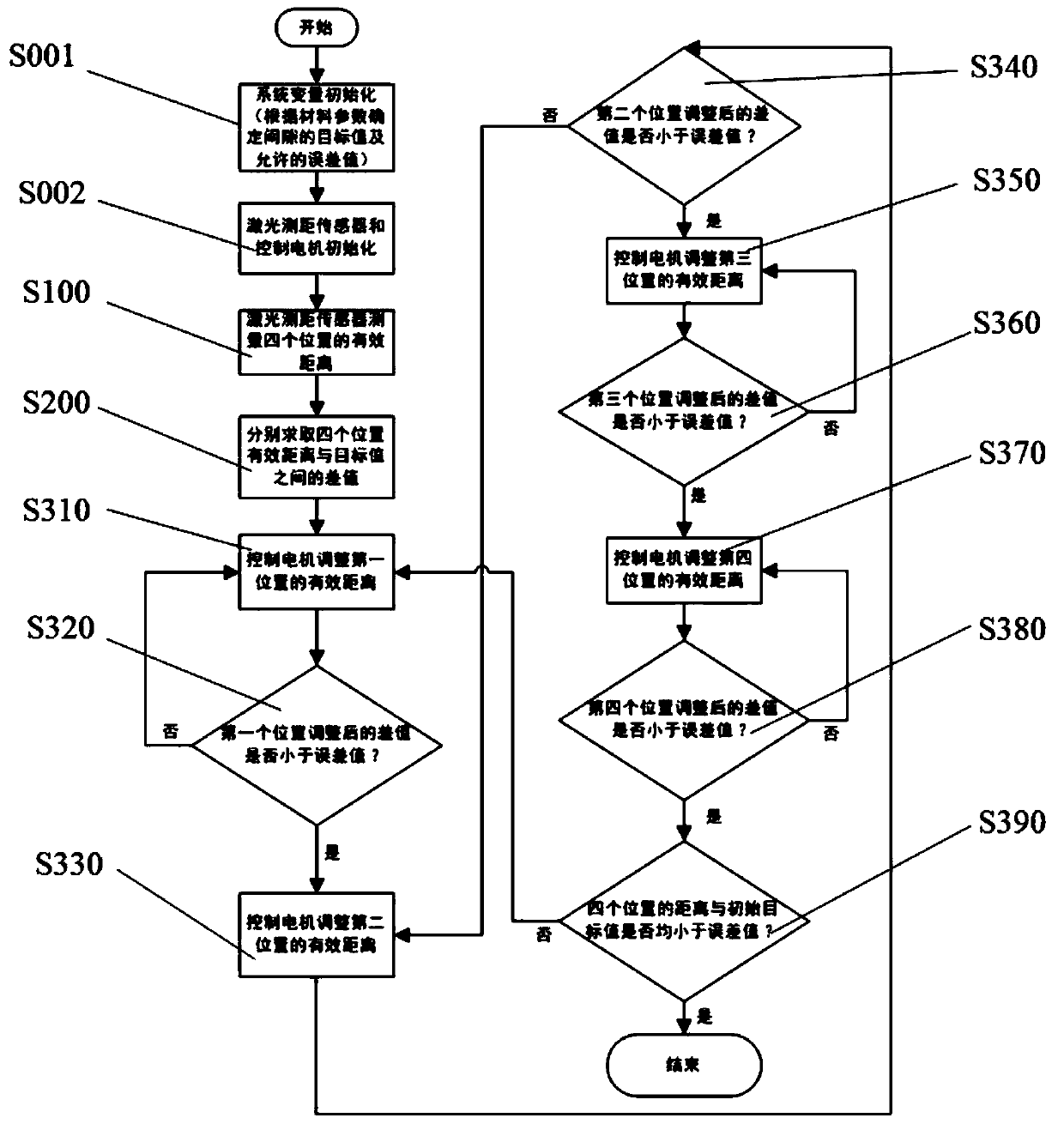

[0031] combined with Figure 1 to Figure 3 Describe the specific implementation of the present invention: the present invention is an automatic leveling device and leveling method for fused deposition additive manufacturing, such as figure 1 As shown, the device includes a printing platform 1, a nut 2, a lead screw 3, a control motor 4, a laser ranging sensor 5 and a controller, and the four nuts 2 are fixedly installed on the printing platform 1 through fixing sleeves and distributed At the four corners below the printing platform; the bottom of each nut 2 is fitted with a lead screw 3, the axis of the lead screw 3 is perpendicular to the plane where the printing platform is located; the lead screw 3 is fixed to the output shaft of the control motor 4 Installation, the input end of the control motor 4 is connected with the output end of the controller; the laser ranging sensor 5 can be installed on the nozzle 6 of the 3D printer through a vertical guide rail, or not installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com