Full-automatic hand-eye calibration and working plane calibration method and device

A working plane, hand-eye calibration technology, applied in the field of robot calibration, can solve the problems of complex calibration process, inability to guarantee accuracy, and inability to provide obstacle avoidance functions, and achieve the effect of improving calibration efficiency, reducing manual intervention, and making clear evaluations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

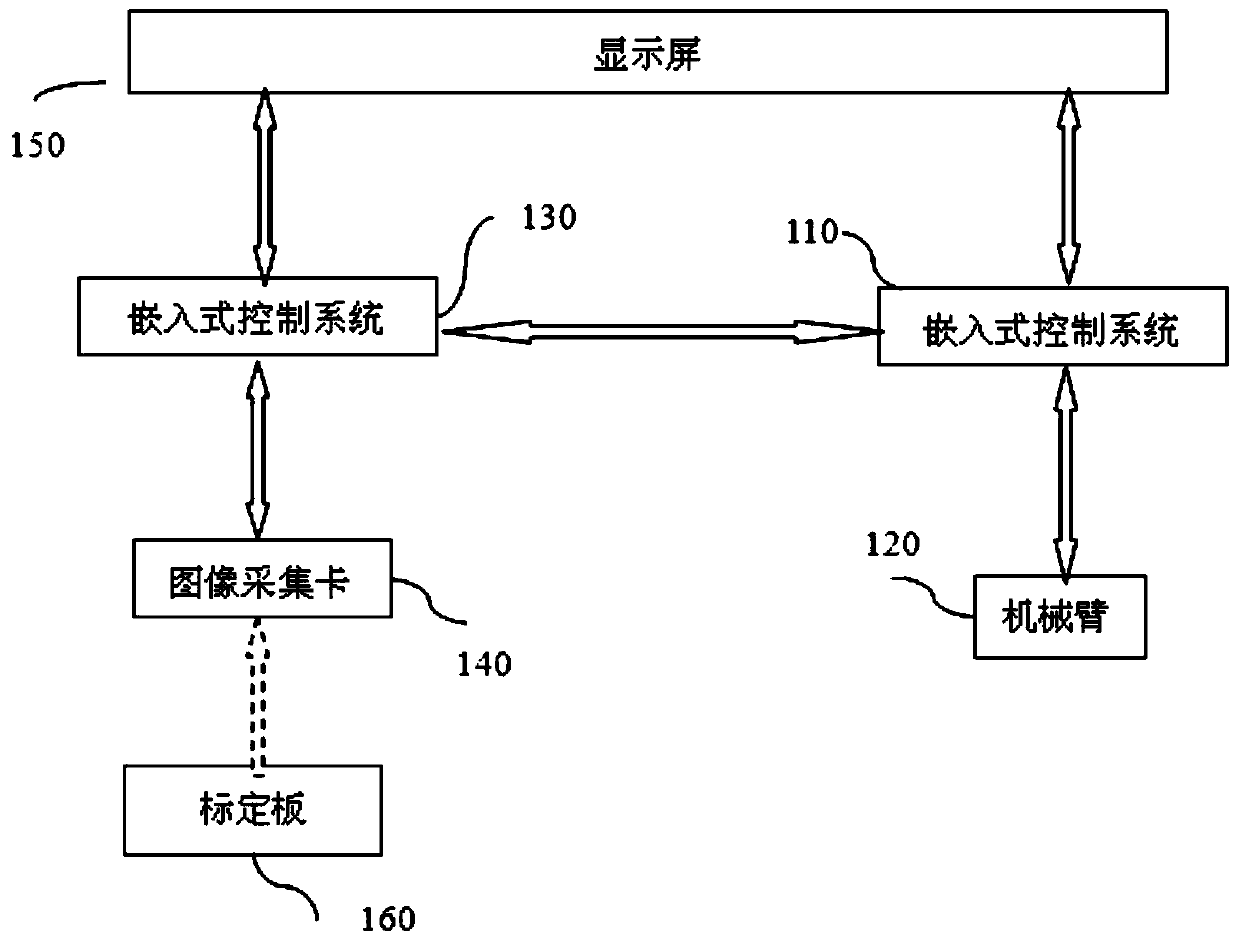

[0028] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

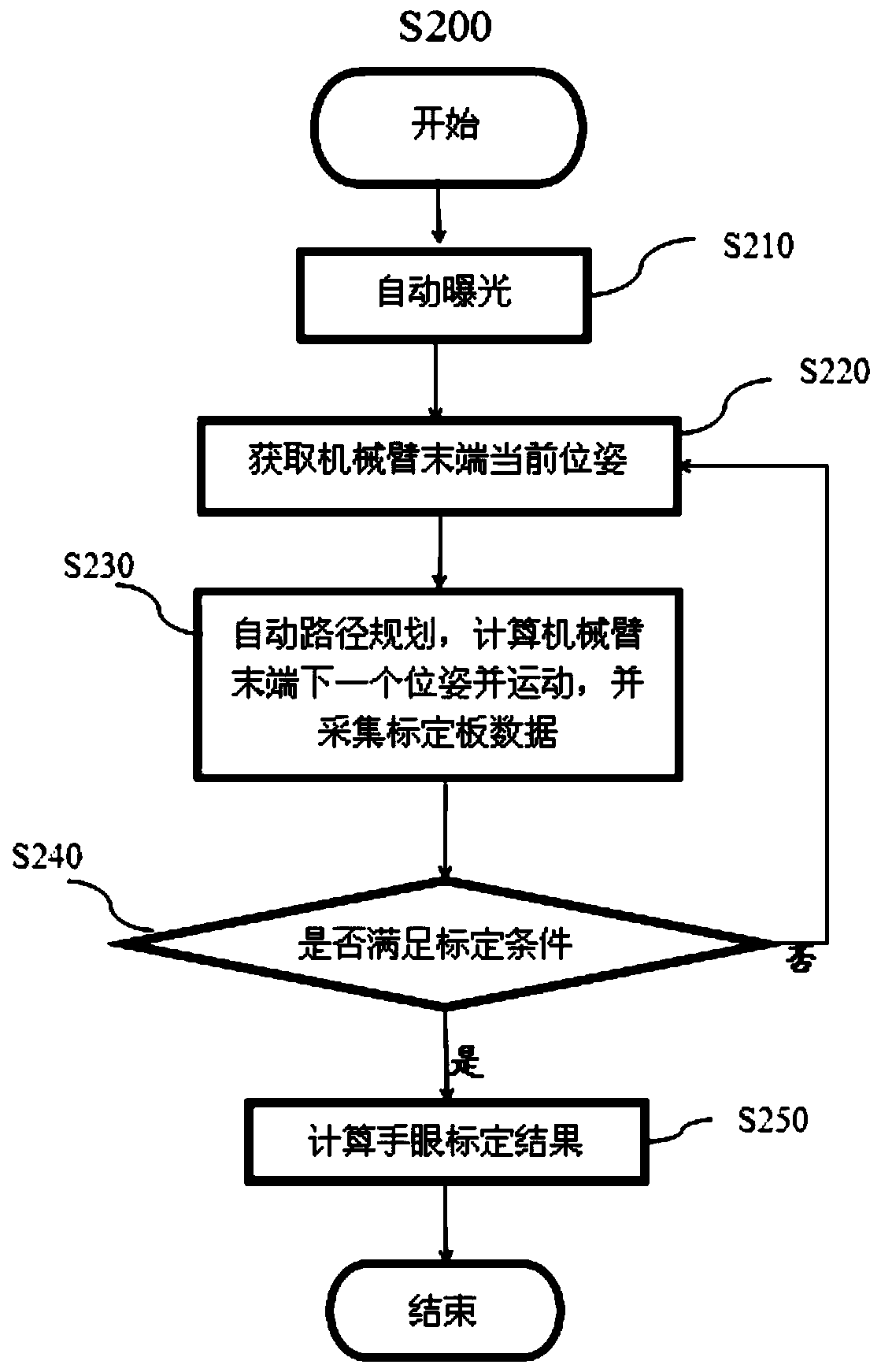

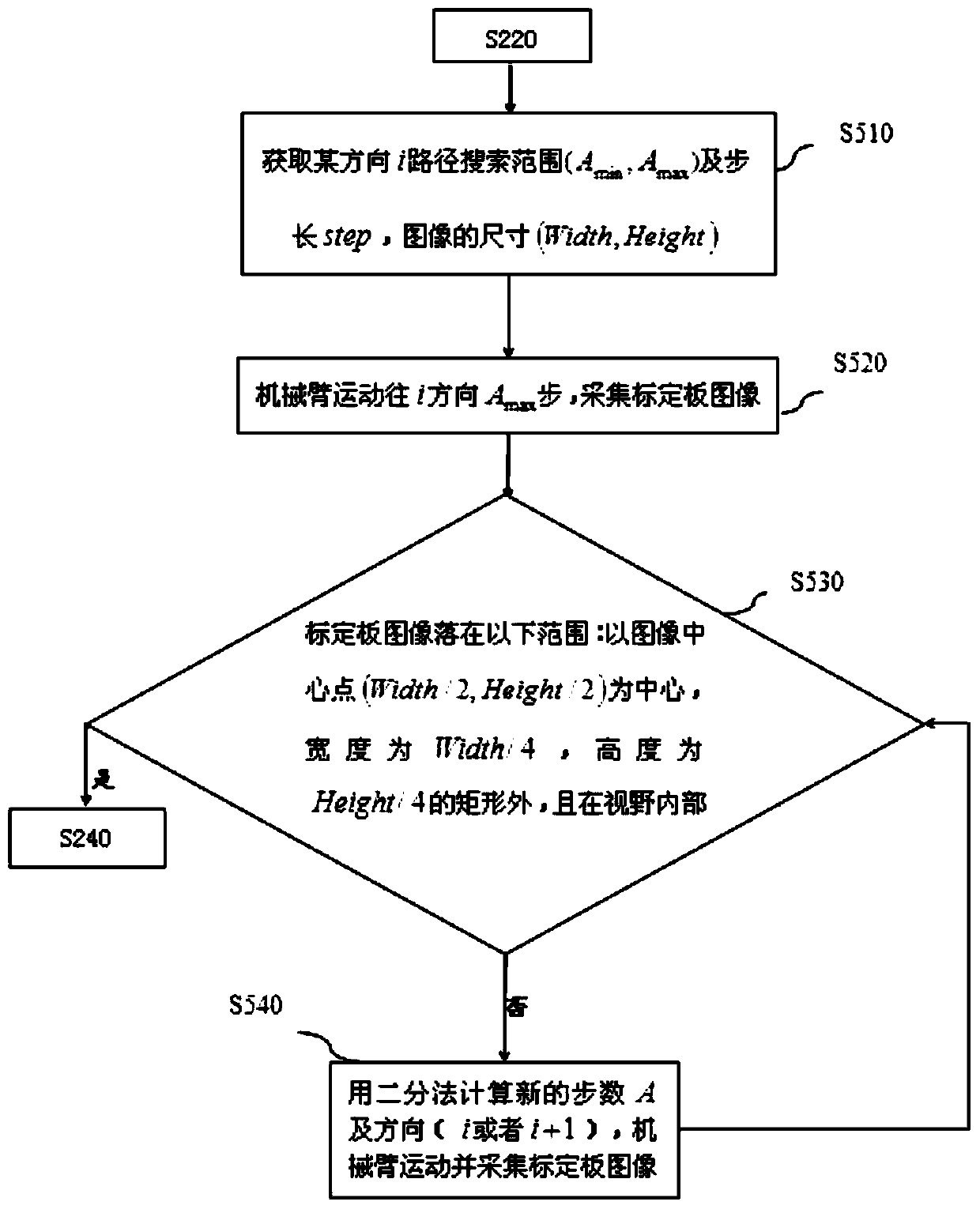

[0029] The invention provides a fully automatic hand-eye calibration and working plane calibration method, comprising the following steps: 1) automatic exposure to ensure that the calibration board can be identified; 2) obtaining the current pose of the end of the mechanical arm and the image data of the calibration board, and The automatic path planning method calculates the next pose of the end of the manipulator; 3) Determine whether there are at least nine calibration board images covering the entire image field of view; 4) If not, continue to collect the pose of the manipulator and the calibration board image; if there are , the hand-eye relationship matrix is calculated according to the pose data of the manipulator and the image data of the calibration board, and the camera internal parameters and the current working plane are calibrated at the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com