Quick positioning assembly steel ring fixing device

A technology of fixing device and steel collar, applied in the field of steel collar, can solve problems such as affecting the construction and installation progress, increasing the difficulty of transportation, etc., and achieves the effects of high practical value and promotion value, simple structure, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

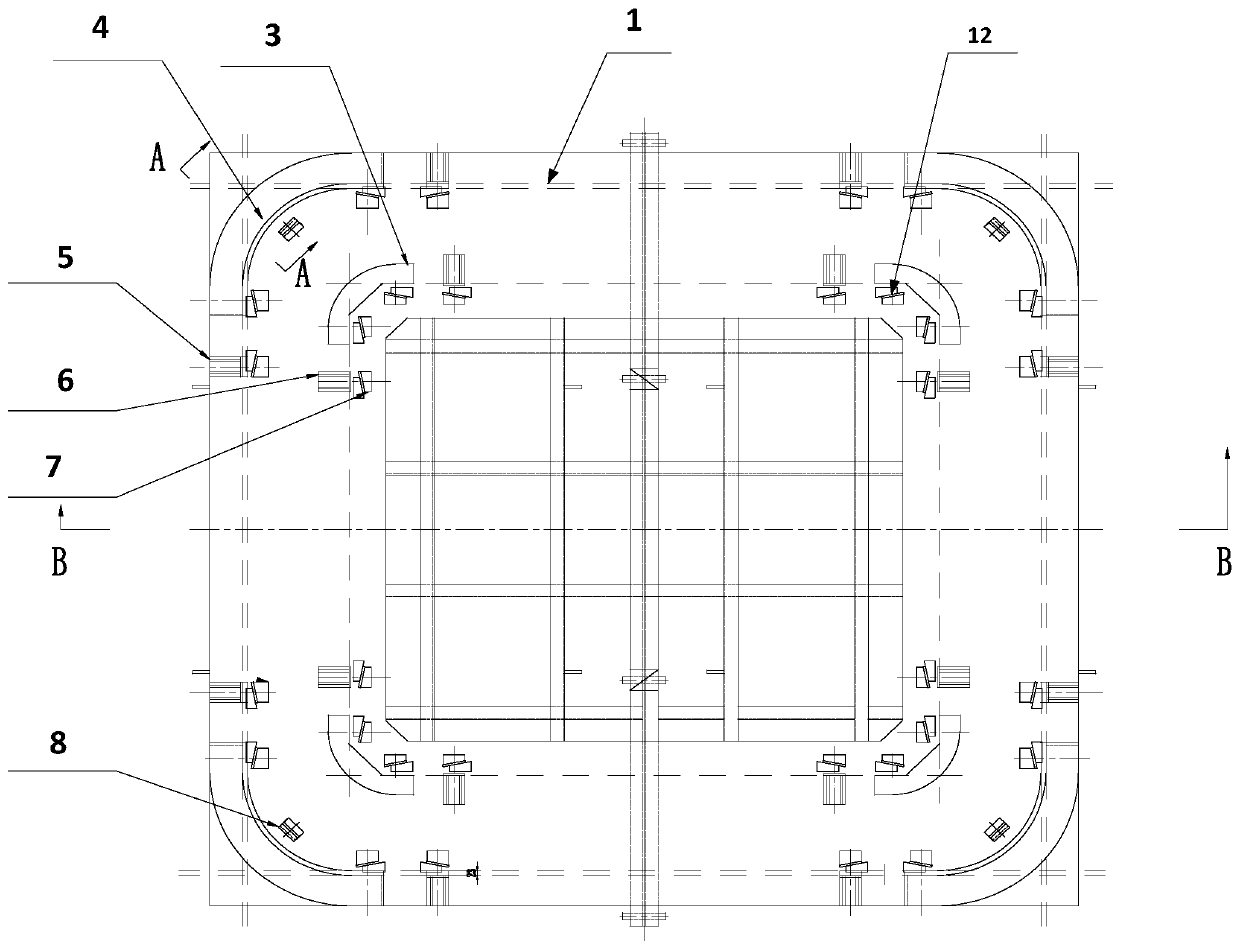

[0022] Such as Figures 1 to 5 As shown, this embodiment provides a fast positioning and assembly steel collar fixing device, which is used for on-site positioning, welding and assembly of the inner steel collar and the outer steel collar. It should be noted that the serial numbers such as "first" and "second" in this embodiment are only used to distinguish similar components, and should not be understood as specific limitations on the scope of protection.

[0023] In this embodiment, the fast positioning and assembling steel collar fixing device includes a base 2 which is arranged on the ground and has a cube structure. The two first stop seats 5 on both sides of the side center line of the outer steel collar 1 are welded on the base 2 and arranged in one-to-one correspondence with any first stop seat 5 for clamping the outer The fifth retaining seat 10 on one side of the steel collar is symmetrical to the center line of any side of the inner steel collar, welded on the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com