An inner positive pressure combined seed metering device

A combined seed metering device technology, applied in sowing, sowing seeders, agriculture, etc., can solve the problems of high leakage rate, poor adsorption or pressure adhesion performance, short filling time, etc., to reduce the leakage rate , Improve the uniformity of seeding and increase the number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

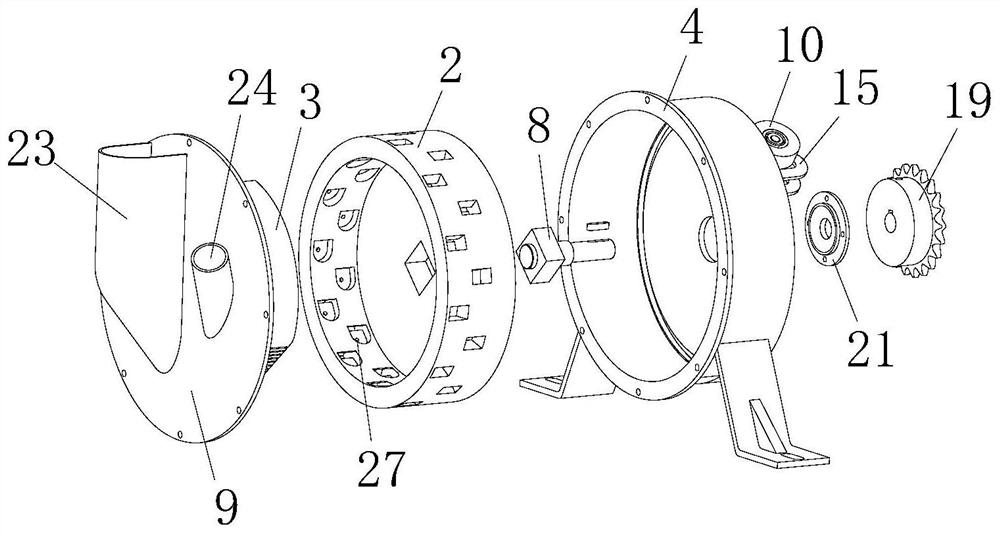

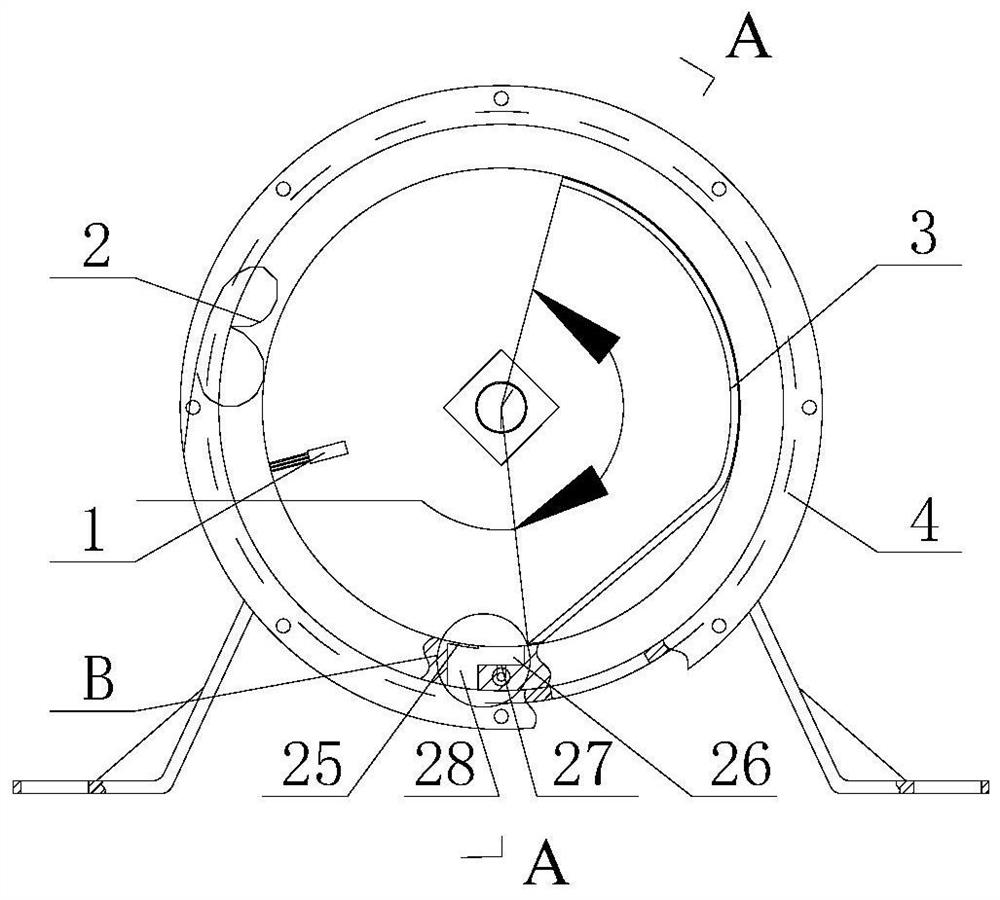

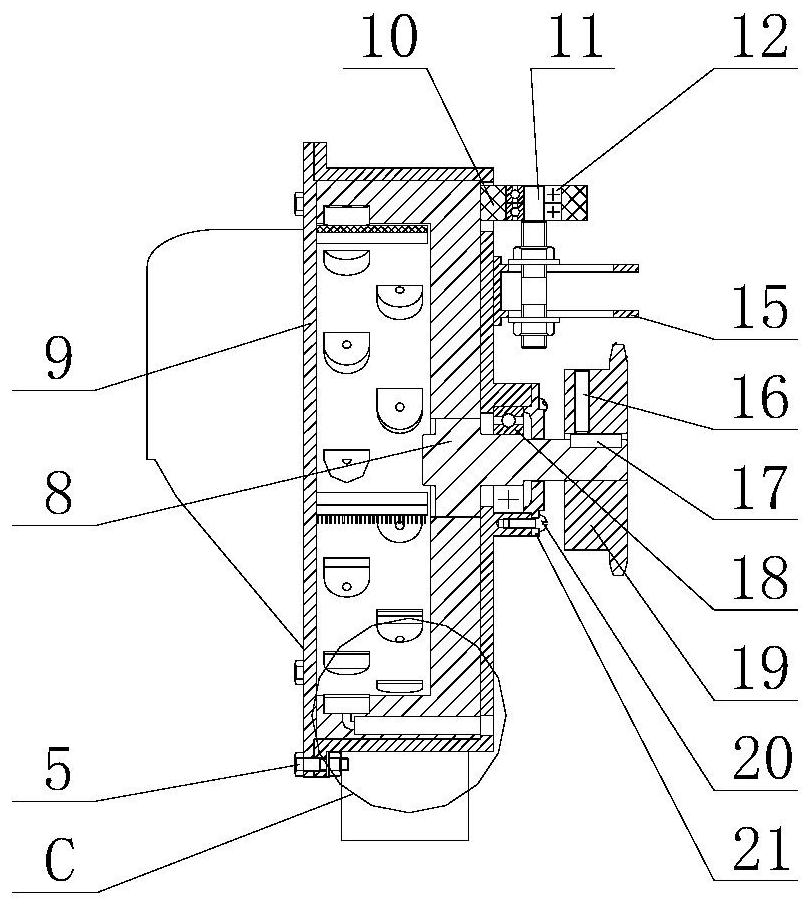

[0031] Such as figure 1 , Figure 5 The shown positive pressure combined seed metering device includes a front housing 9 with a seed inlet 23 and a positive pressure hole 24, a rear housing 4 with a seed inlet 31, a seed tray 2, and a seed discharge wheel. 10 and the seeding shaft 8, wherein the edge of the front housing 9 is provided with several first through holes 22 along the circumference, and the edge of the rear housing 4 is provided with a second through hole 30 matched with the first through holes 22 along the circumference, The front housing 9 and the rear housing 4 are arranged in abutment and are fixedly connected by hexagon socket head cap screws 5 , and the seed tray 2 is located in the space formed by the affixing of the front housing 9 and the rear housing 5 . Such as figure 2 , 3 As shown, the seeding shaft 8 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com