Refinery excess sludge dewatering method and refinery excess sludge dewatering apparatus

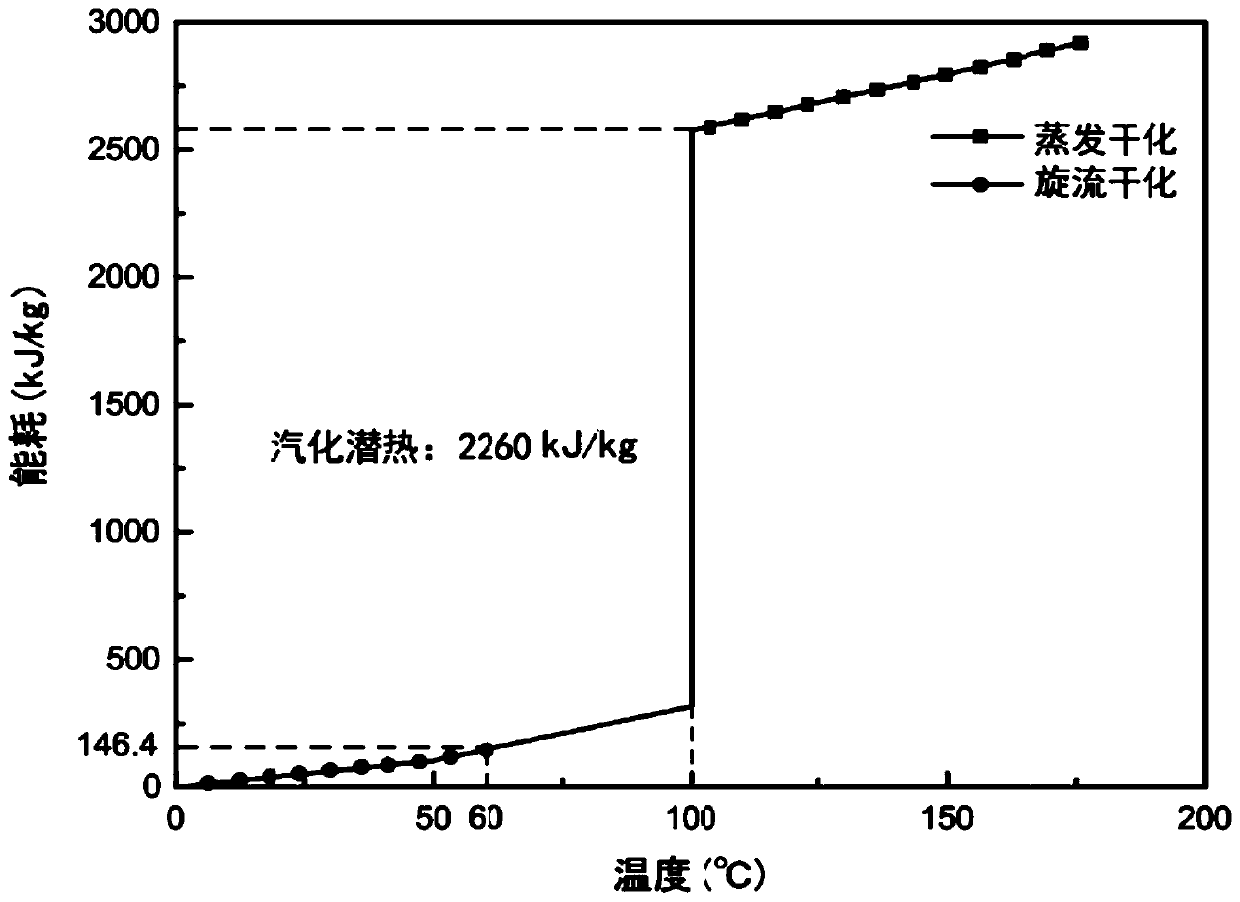

A technology for excess sludge and oil refineries, applied in the direction of water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve unfavorable transportation, storage and digestion, poor dehydration effect, complicated process flow and other problems to achieve the effect of high dehydration efficiency, convenient operation and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

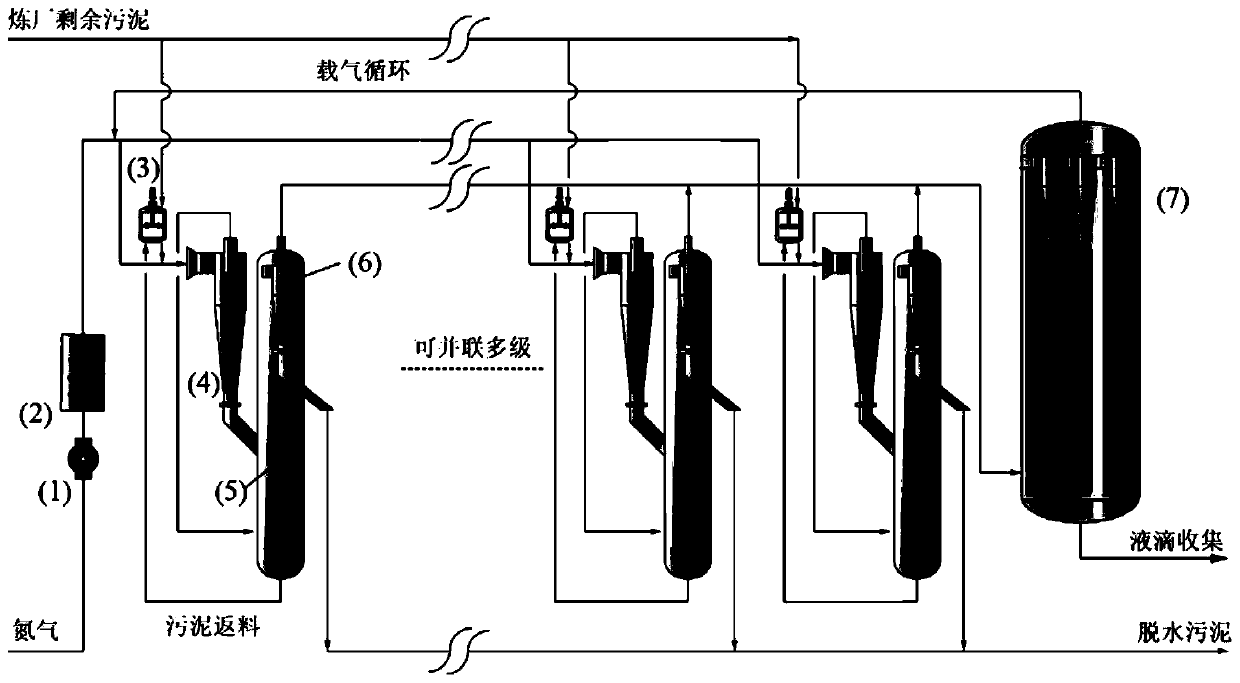

[0073] In a deep dewatering device for surplus sludge in an oil refinery, the deep dehydration of surplus sludge is carried out according to the method and device of the present invention, and its specific operation process and effects are described as follows:

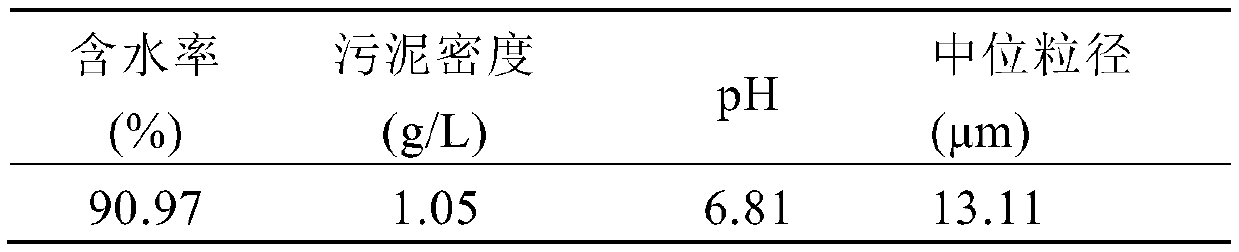

[0074] 1. Properties of excess sludge

[0075] The excess sludge used comes from the excess sludge of Shanghai Secco Petrochemical Co., Ltd. After the biochemical excess sludge of Secco Petrochemical is dehydrated by a centrifuge, the moisture content is still 90.9% by weight, and the average particle size is 13.1μm. The mud properties are shown in Table 1 below.

[0076] Table 1: Properties of Aqueous Sludge

[0077]

[0078] 2. Implementation process

[0079] Implement with reference to the method of the present invention, specifically as follows:

[0080] In this embodiment, the material is water-containing sludge, and air is selected as the gas for the swirling and autorotation dehydration of the sludge and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com