Corona treatment equipment for surface of injector tube body

A syringe barrel and corona treatment technology, applied in printing, printing machines, household components, etc., can solve the problems of poor printing firmness and clarity, low ink adhesion on the surface of the barrel, and can not meet the requirements of industry development, etc. The effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

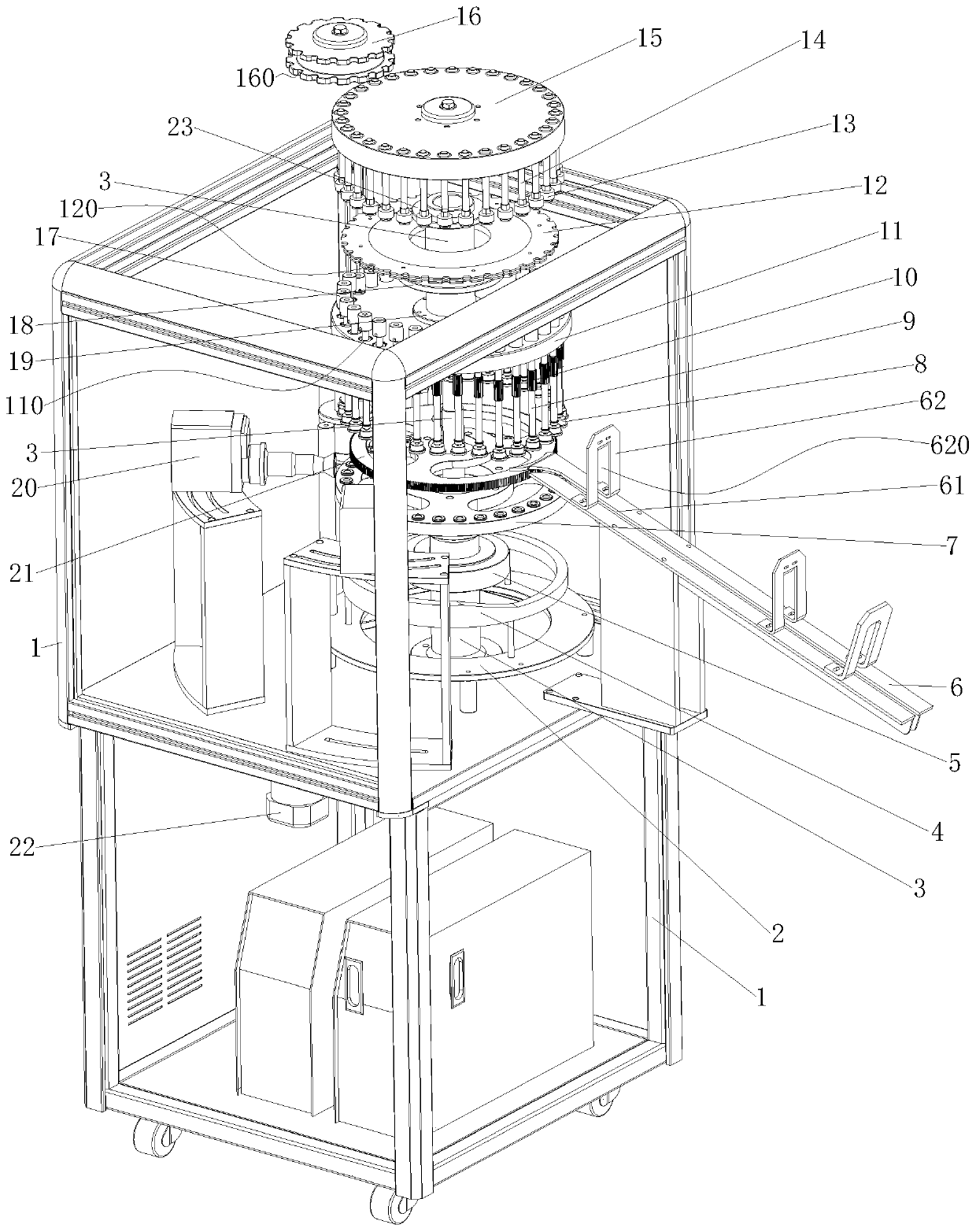

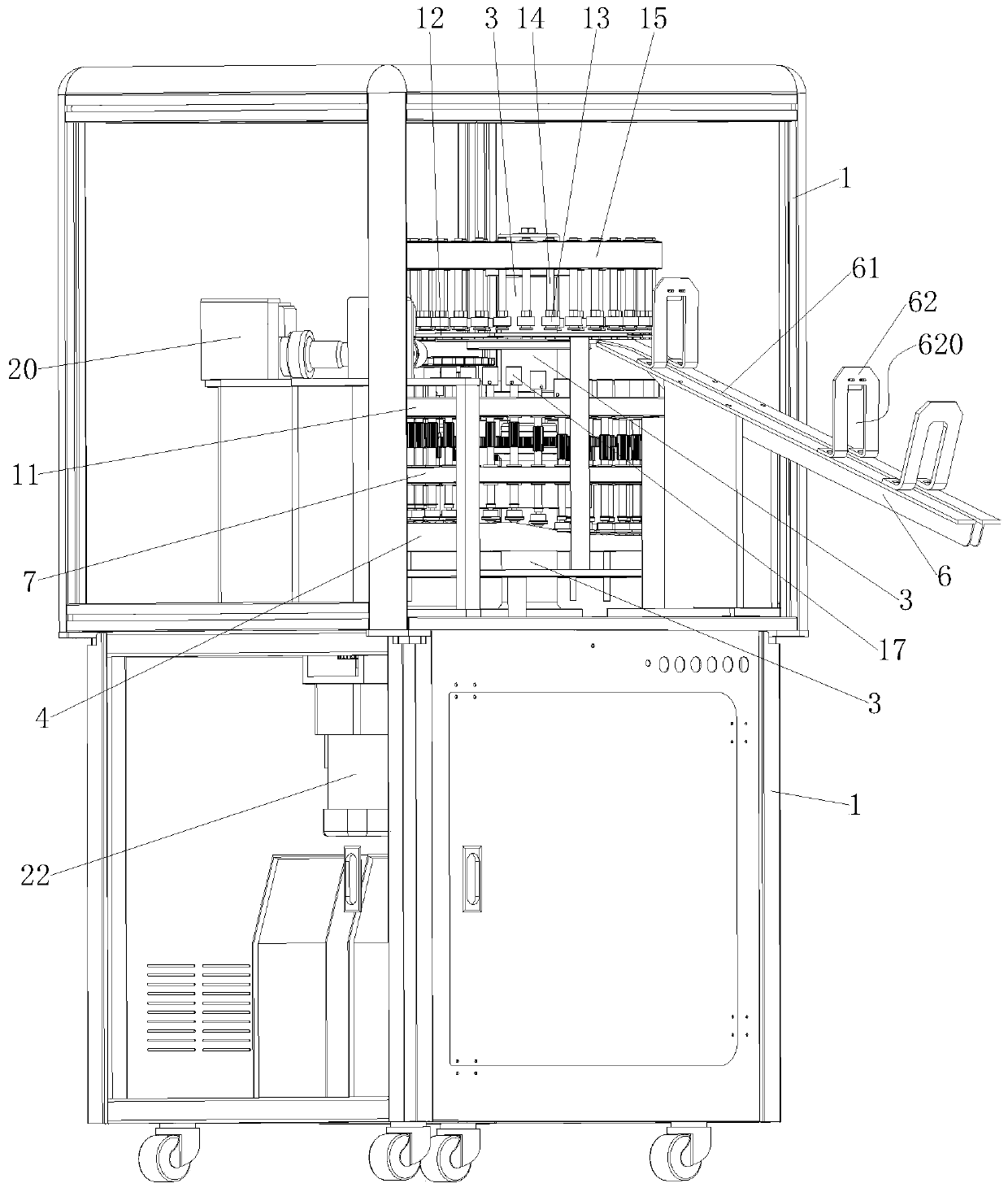

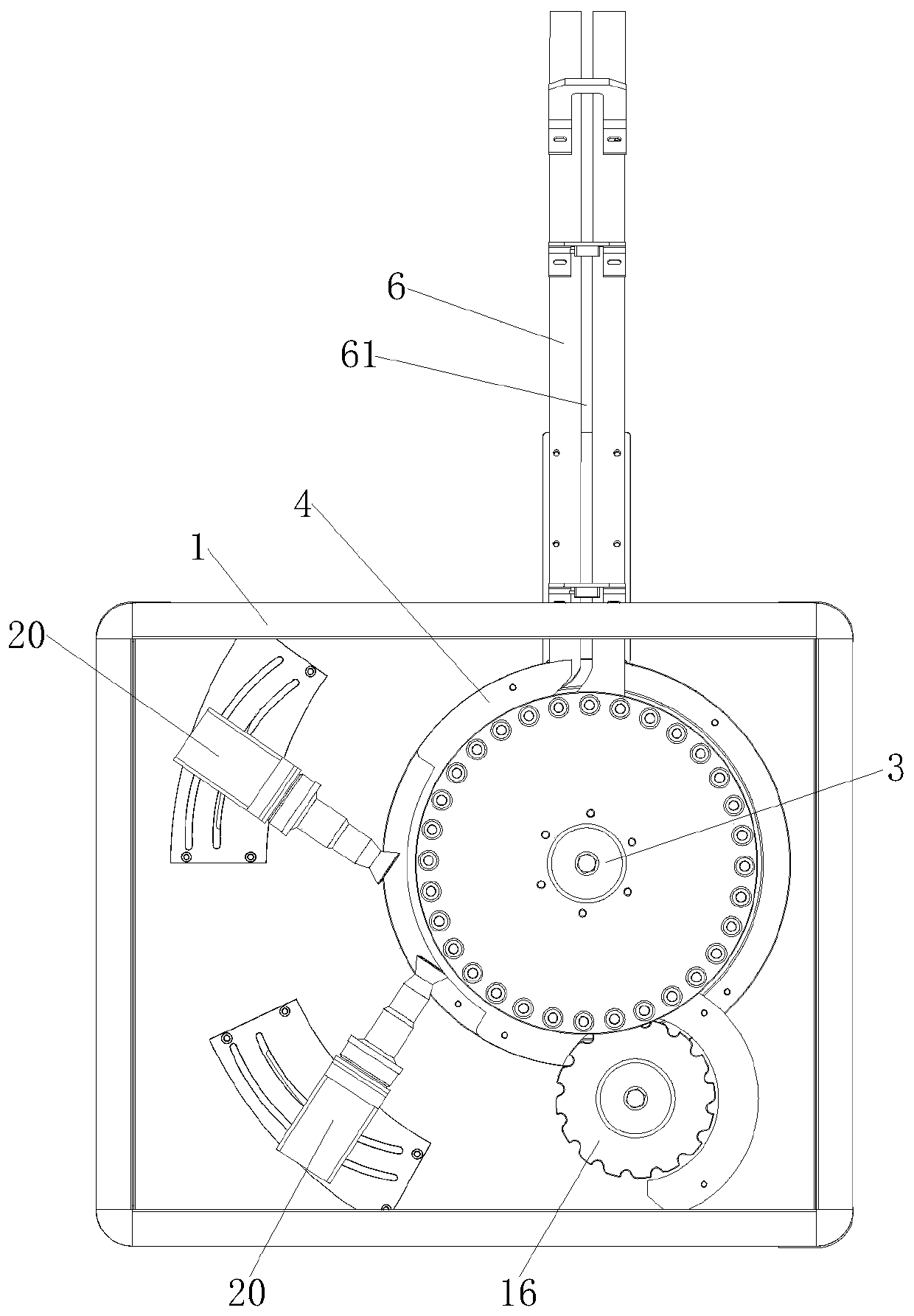

[0029] Syringe barrel surface corona treatment equipment, such as Figure 1-5 As shown, it includes a frame 1, a feeding mechanism for placing and delivering the syringe barrel 17, a pressing mechanism for receiving the syringe barrel 17 delivered by the feeding mechanism and pre-tightening the syringe barrel 17, and a pressing mechanism for receiving the upper syringe barrel 17. The syringe cylinder 17 delivered by the pressing mechanism and drives the syringe cylinder 17 to rotate so that the syringe cylinder 17 passes through the guide mechanism of the corona treatment area, the transmission mechanism used to drive the guide mechanism to rotate or move up and down, and the drive mechanism used to drive the transmission mechanism , a corona treatment machine 20 for performing corona treatment on the surface of the syringe cylinder 17 that ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com