Power battery pack, energy storage device and electric vehicle

A technology for power battery packs and single cells, which is applied in power units, electric power units, electric vehicles, etc., can solve the problem that the battery life of the power battery pack cannot be effectively improved, the utilization rate of the installation area of the chassis is low, and the increase of the accommodating device Production process complexity and other issues to achieve the effect of improving battery life, achieving lightweight, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

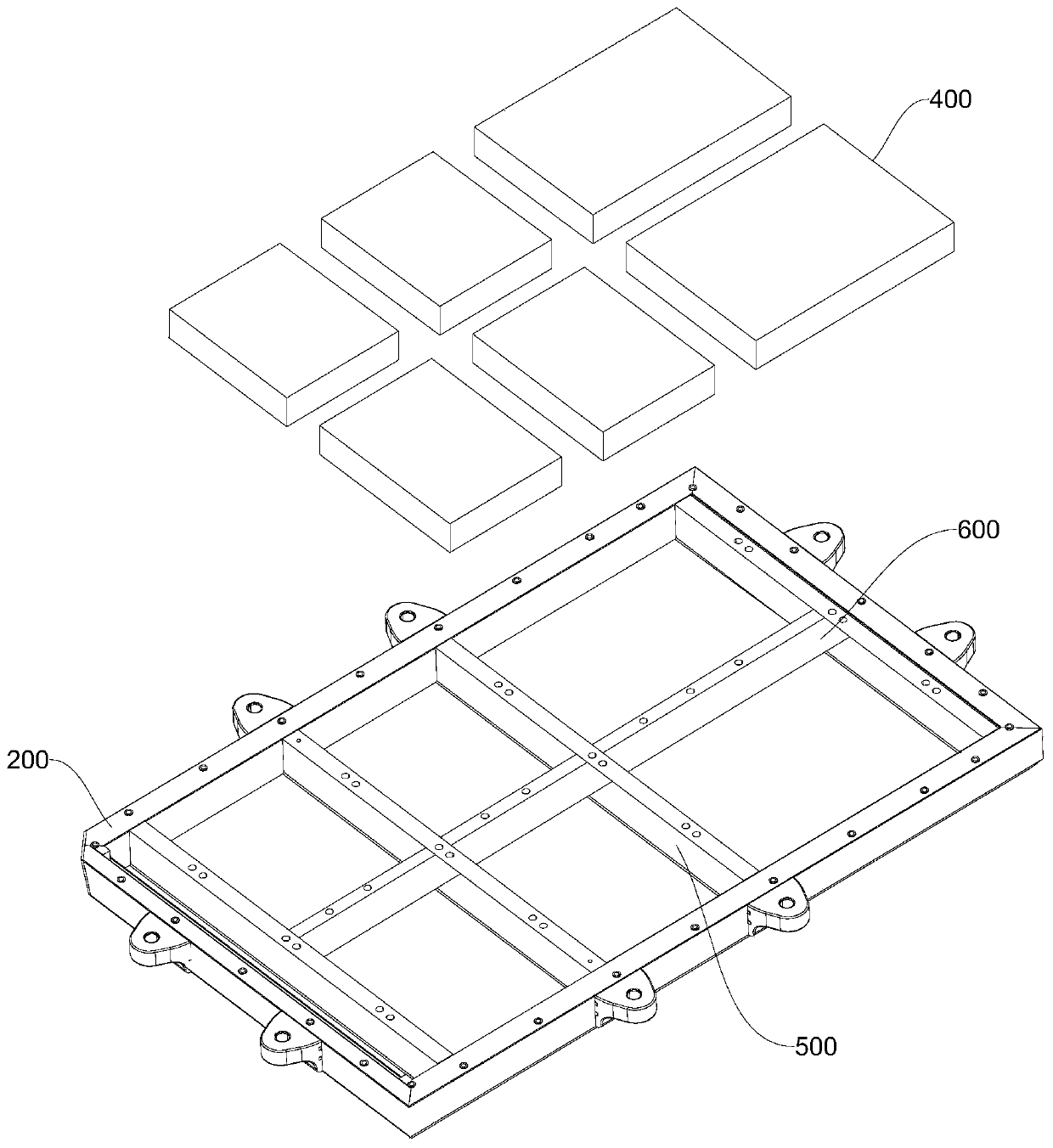

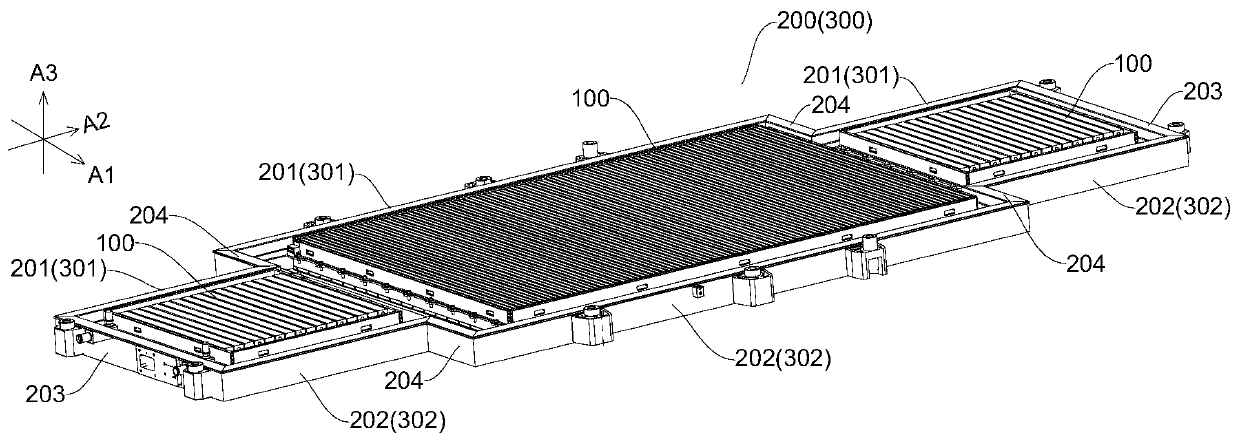

[0186] As an implementation manner, the power battery pack is arranged at the bottom of the electric vehicle, and the accommodating device 200 is fixedly connected to the chassis of the electric vehicle. Since the installation space at the chassis of the electric vehicle is large, disposing the power battery pack at the chassis of the electric vehicle can increase the number of single batteries 100 as much as possible, thereby improving the battery life of the electric vehicle. Here, there may be one or more power battery packs arranged at the bottom of the electric vehicle.

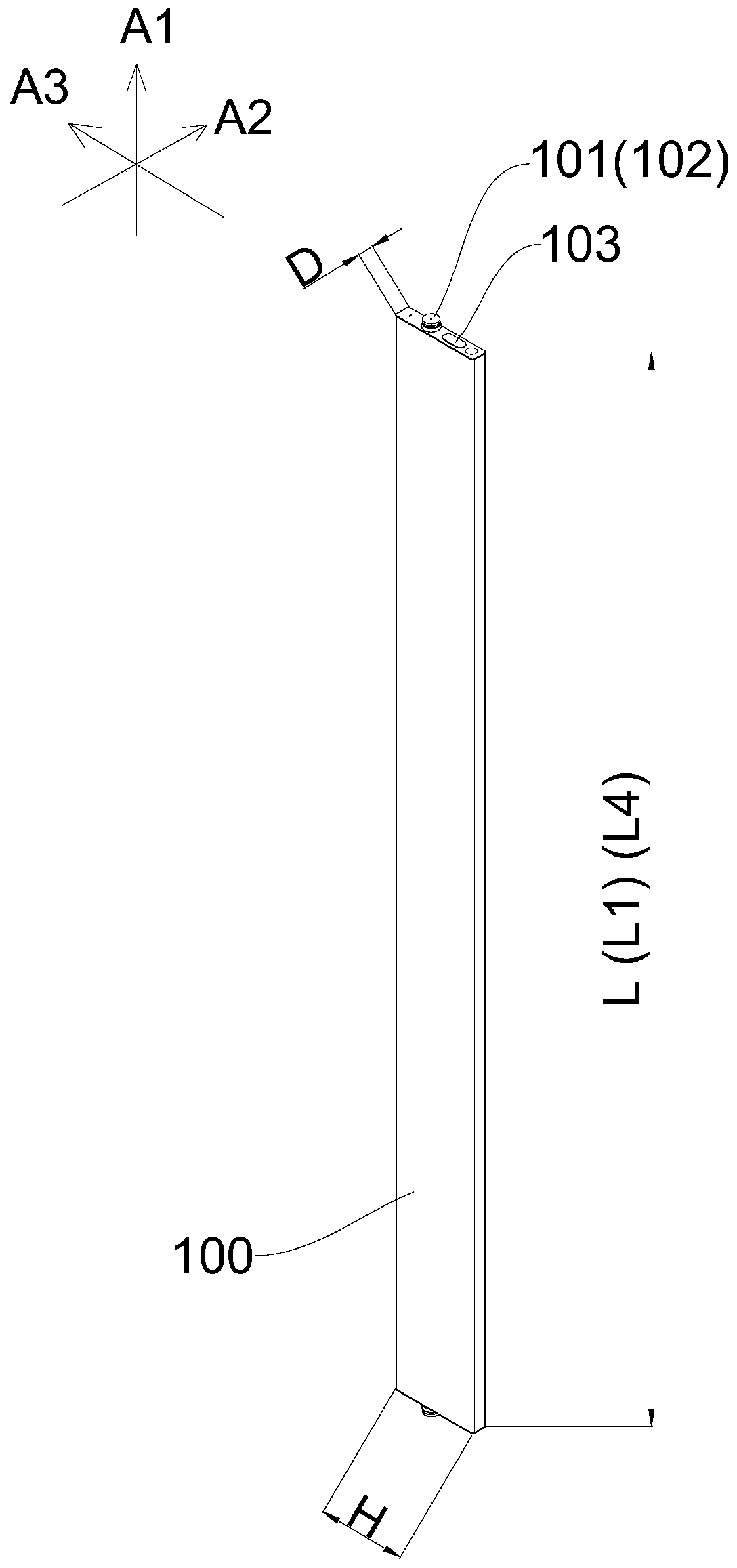

[0187] Optionally, the electric vehicle includes a power battery pack disposed at the bottom of the electric vehicle, the accommodating device 200 is fixedly connected to the chassis of the electric vehicle, and the plurality of single batteries 100 are arranged along a second direction A2 different from the first direction A1, The first direction A1 is the vehicle body width direction of the electric ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com