An out-of-box travel switch shaft body

A travel switch and shaft technology, which is applied in the direction of electric switches, contact operating mechanisms, electrical components, etc., can solve the problems of misjudgment of the control system out of the box, output of the box signal in advance, small frictional resistance, etc., and achieve high-quality work Characteristics, optimized process, effect of low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

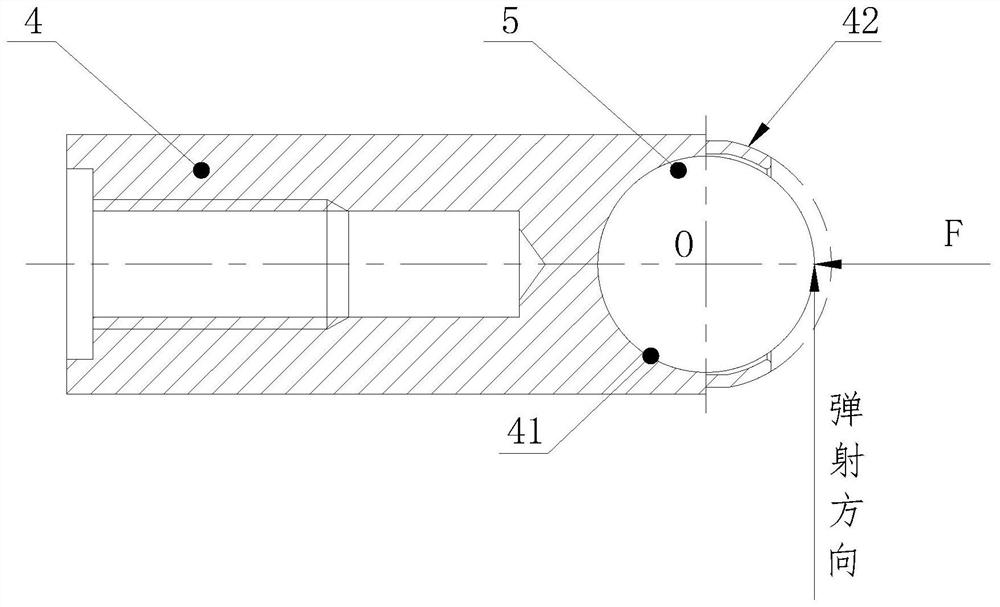

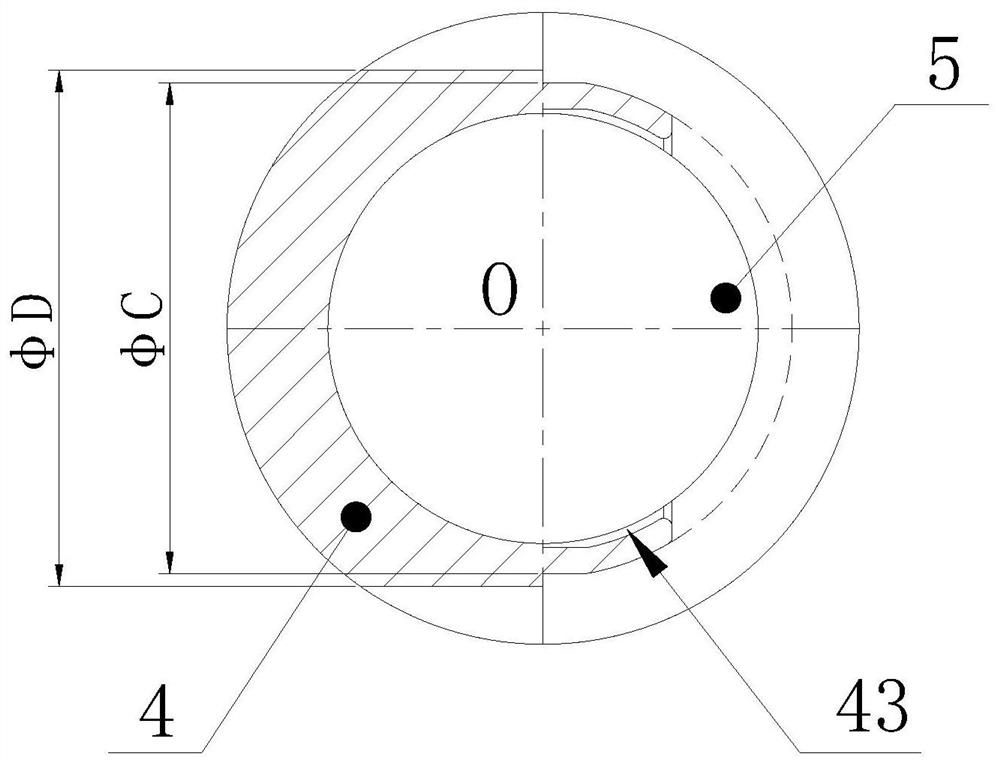

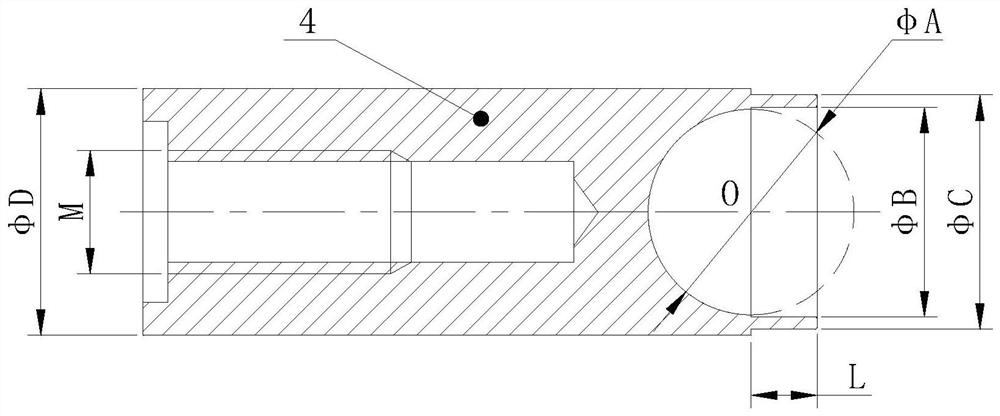

[0025] like Figure 1-3 As shown, an out-of-box limit switch shaft body includes a shaft body 4 and a steel ball 5. The shaft body 4 is a cylinder, and the bottom end of the shaft body 4 is a "U" cavity structure, which consists of a hemisphere with a diameter of φA surface 41 and a circular hole section 42 with an inner diameter of φB and a depth of L; the steel ball 5 is placed in the hemispherical surface 41, and the circular hole section 42 shrinks and locks the steel ball 5 to realize the three-axis limit of the steel ball 5. The steel ball 5 can roll at any angle within 360 degrees in the hemispherical surface 41 . The steel ball 5 rolls at any angle within 360 degrees in the hemispherical surface 41, which can realize the rolling and guiding installation at any angle during the final assembly, so that the friction force of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com