Gear type rubber pipe clamp and sealing method thereof

A gear-type, rubber tube technology, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of pipe shock absorption and noise reduction, and achieve uniform downforce, large contact area, and reduced The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

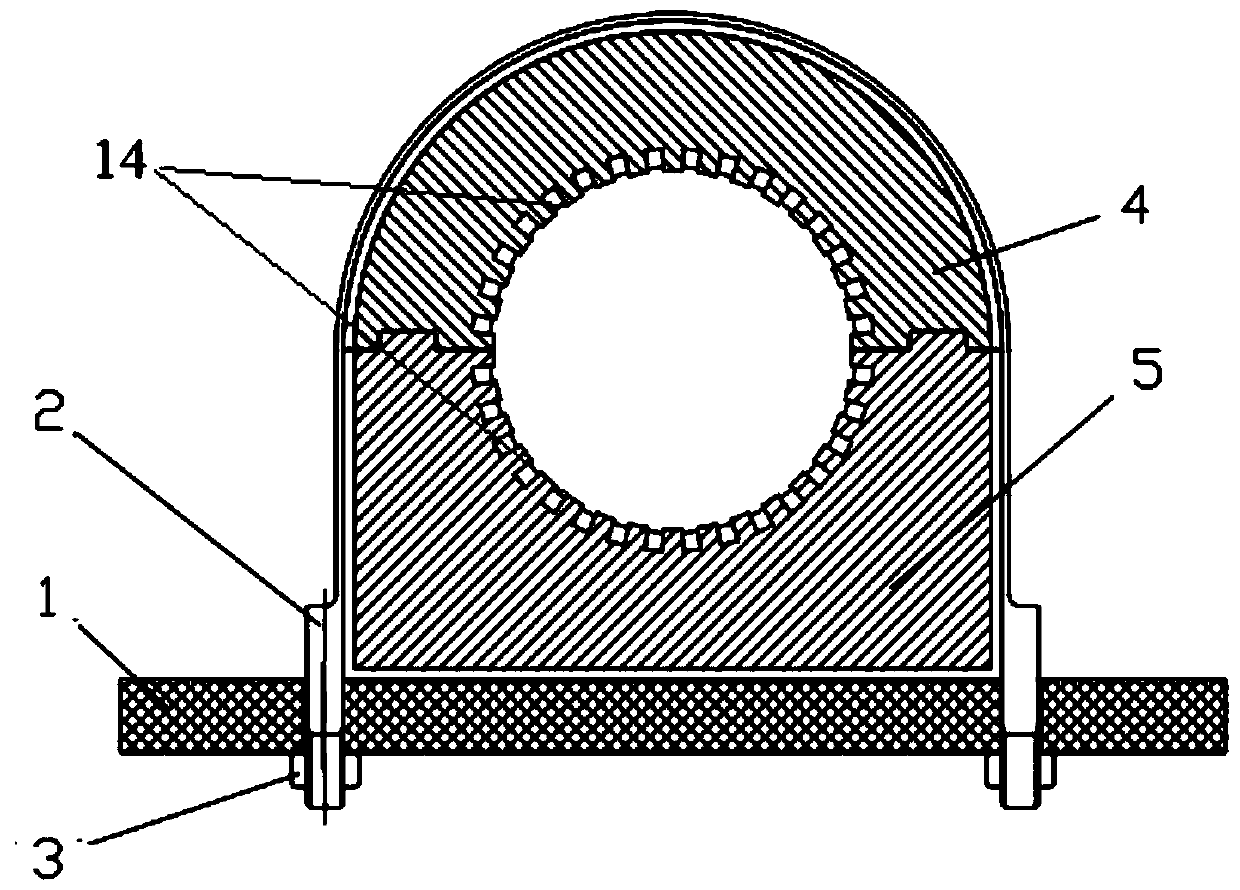

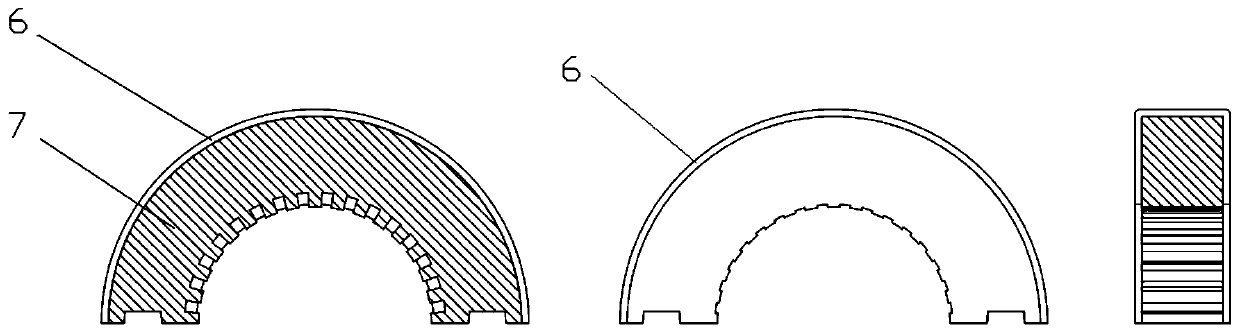

[0038] A gear-type rubber hose clamp, see Figure 1-3 , including an upper pipe clamp 4, a lower pipe clamp 5 and a clip 2, the upper pipe clamp 4 includes an upper pipe clamp housing 6 and an upper pipe clamp filling rubber 7 filled in the upper pipe clamp housing 6, the The lower pipe clamp 5 includes the lower pipe clamp housing 8 and the lower pipe clamp filling rubber 9 filled in the lower pipe clamp housing 8; the upper pipe clamp housing 6 and the lower pipe clamp housing 8 are connected to form a an accommodating chamber for accommodating pipes;

[0039] Both the upper pipe clamp housing 6 and the lower pipe clamp housing 8 are provided with a plurality of gear-type vibration isolation grooves 14 on the inner wall for accommodating the pipeline;

[0040] The clamp 5 is fixedly connected to the target base 1 after locking the upper pipe clamp housing 6 and the lower pipe clamp housing 8 .

[0041] Further, the inner diameter of the upper pipe clamp filling rubber 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com