Rolling bearing installation structure capable of achieving axial undamaged assembly and disassembly

A technology of rolling bearing and mounting structure, which is applied to the components of pumping device for elastic fluid, machine/engine, liquid fuel engine, etc., can solve the problem of not being able to set the axial positioning of rolling bearing to balance its own thrust, etc., and achieve convenient disassembly and assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

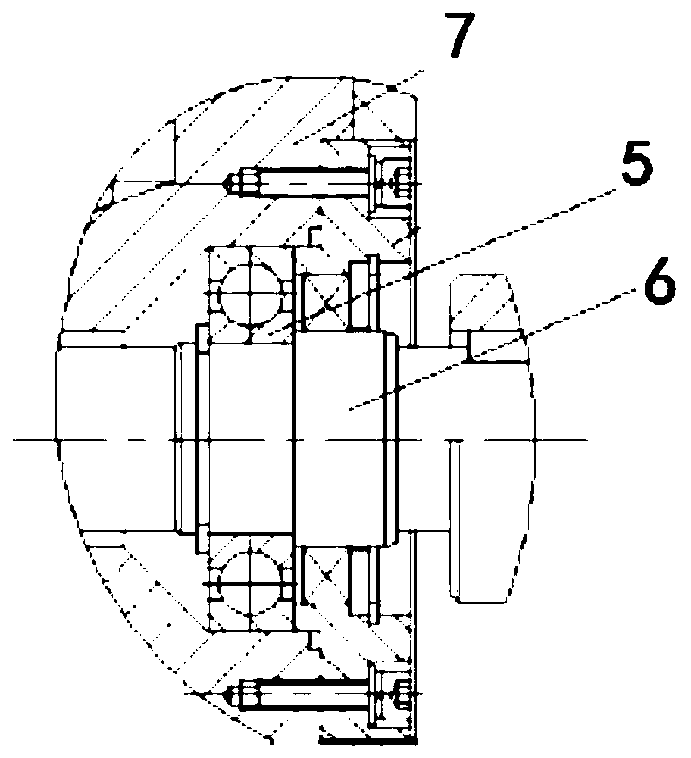

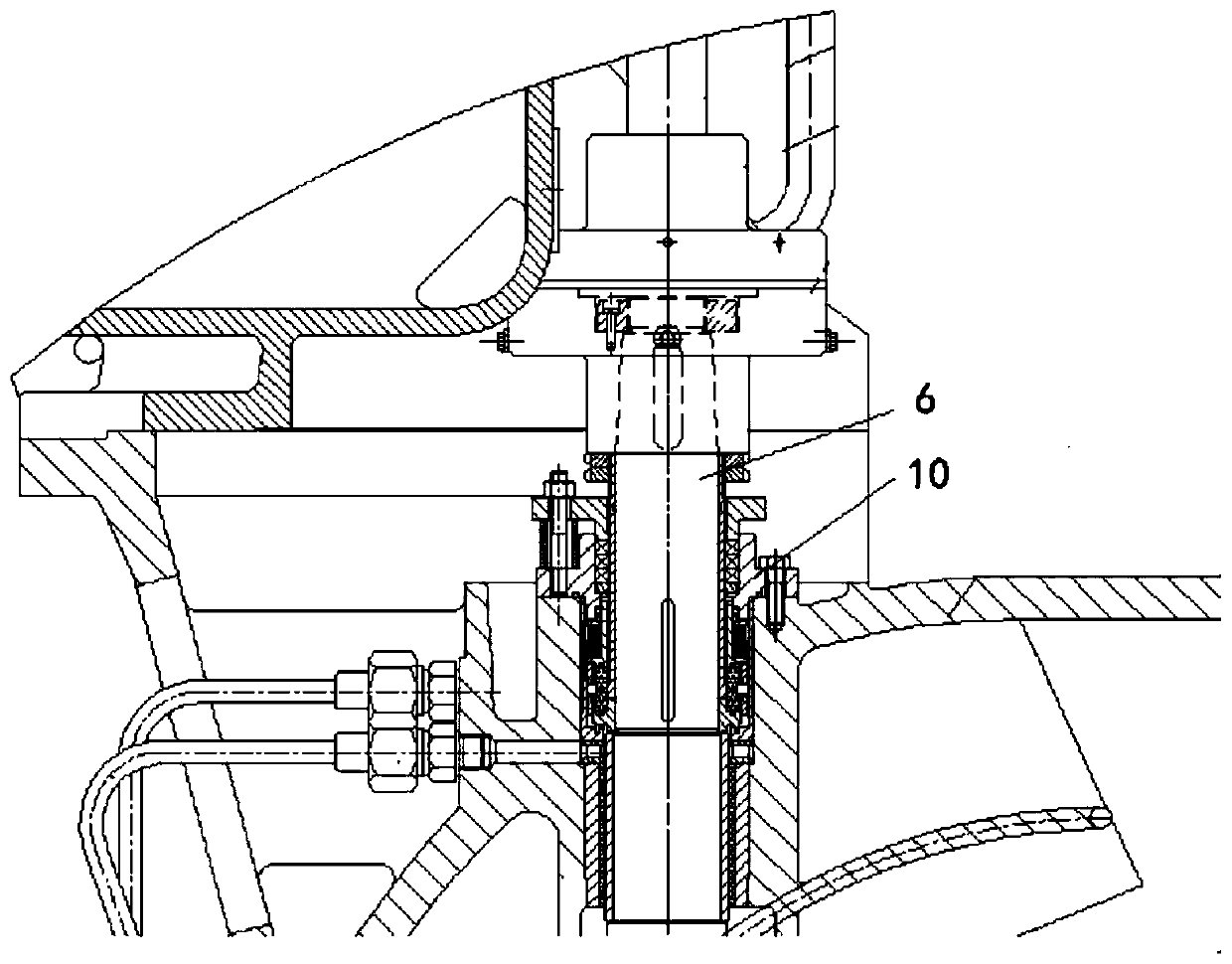

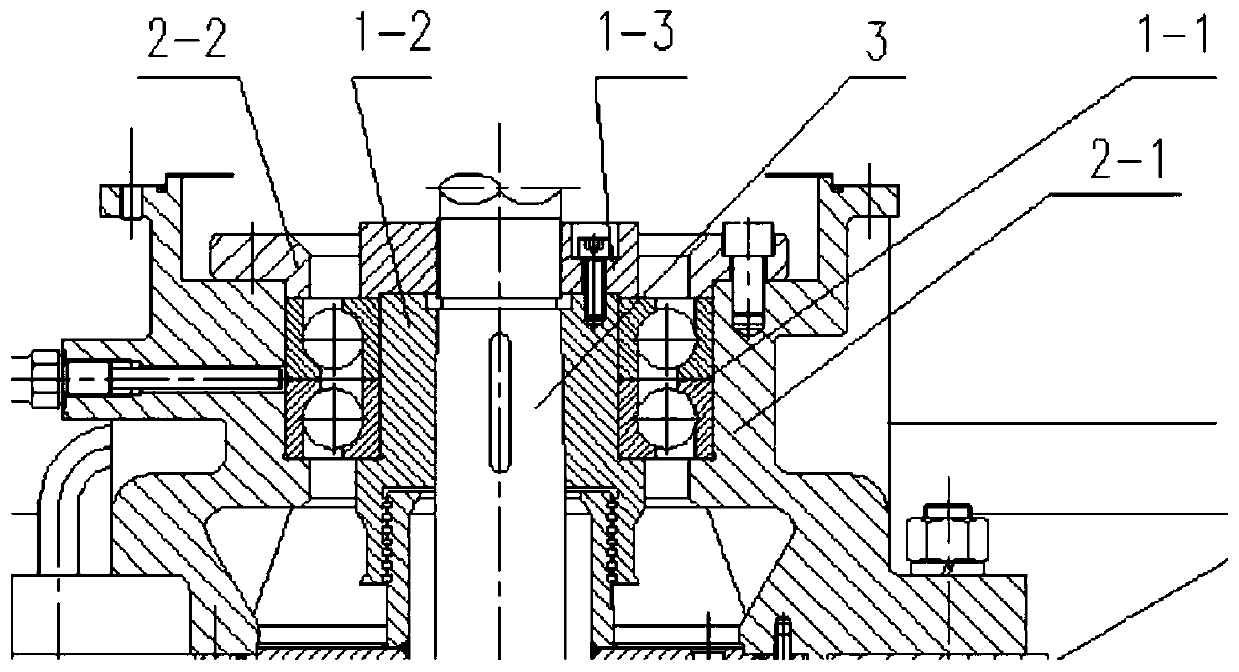

[0020] Such as image 3 As shown, a rolling bearing installation structure that can be assembled and disassembled axially without damage includes a pump shaft 3, a rolling bearing 1-1, a tapered bushing 1-2, an axial positioning nut 1-3, a bearing seat 2-1, a bearing pressure Cover 2-2.

[0021] The front part of the pump rotating shaft 3 has a tapered shaft extension, and the extended end of the tapered shaft extension is processed with threads. The rolling bearing 1-1 is first set on the tapered shaft sleeve 1-2, and the inner hole of the rolling bearing 1-1 is interference-fitted with the outer cylindrical surface of the tapered shaft sleeve 1-2. The inner hole of the tapered bushing 1-2 is a tapered hole, the assembly of the rolling bearing 1-1 and the tapered bushing 1-2 is inserted into the tapered shaft extension of the pump shaft 3, and then s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com