Generator rotor structure and generator

A technology for generator rotors and generators, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as the inability to replace the coil frame, the difficulty in welding the balance block, and the inability to realize the balance adjustment of the unit, so as to reduce the residual unbalance, The effect of reducing vibration noise and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

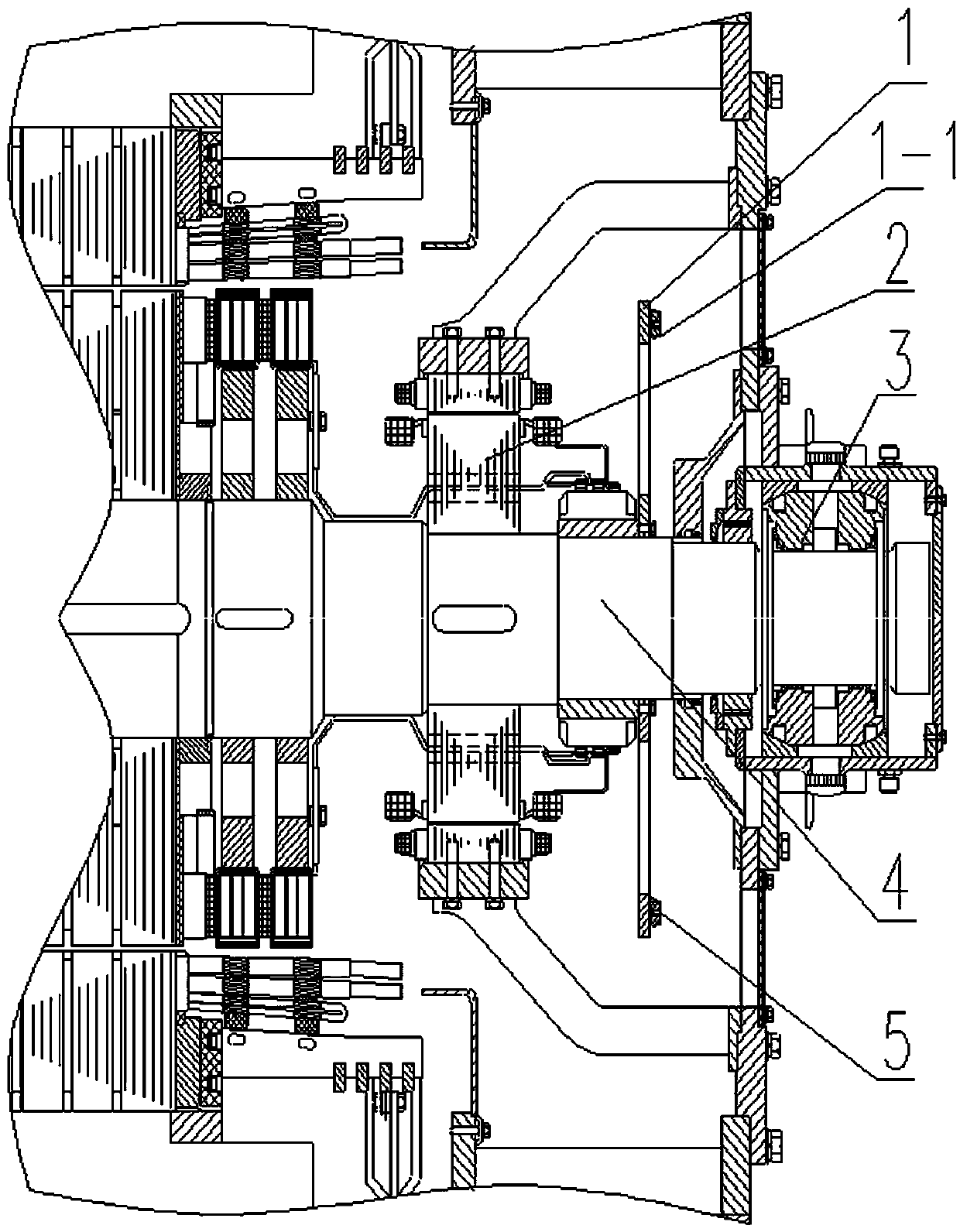

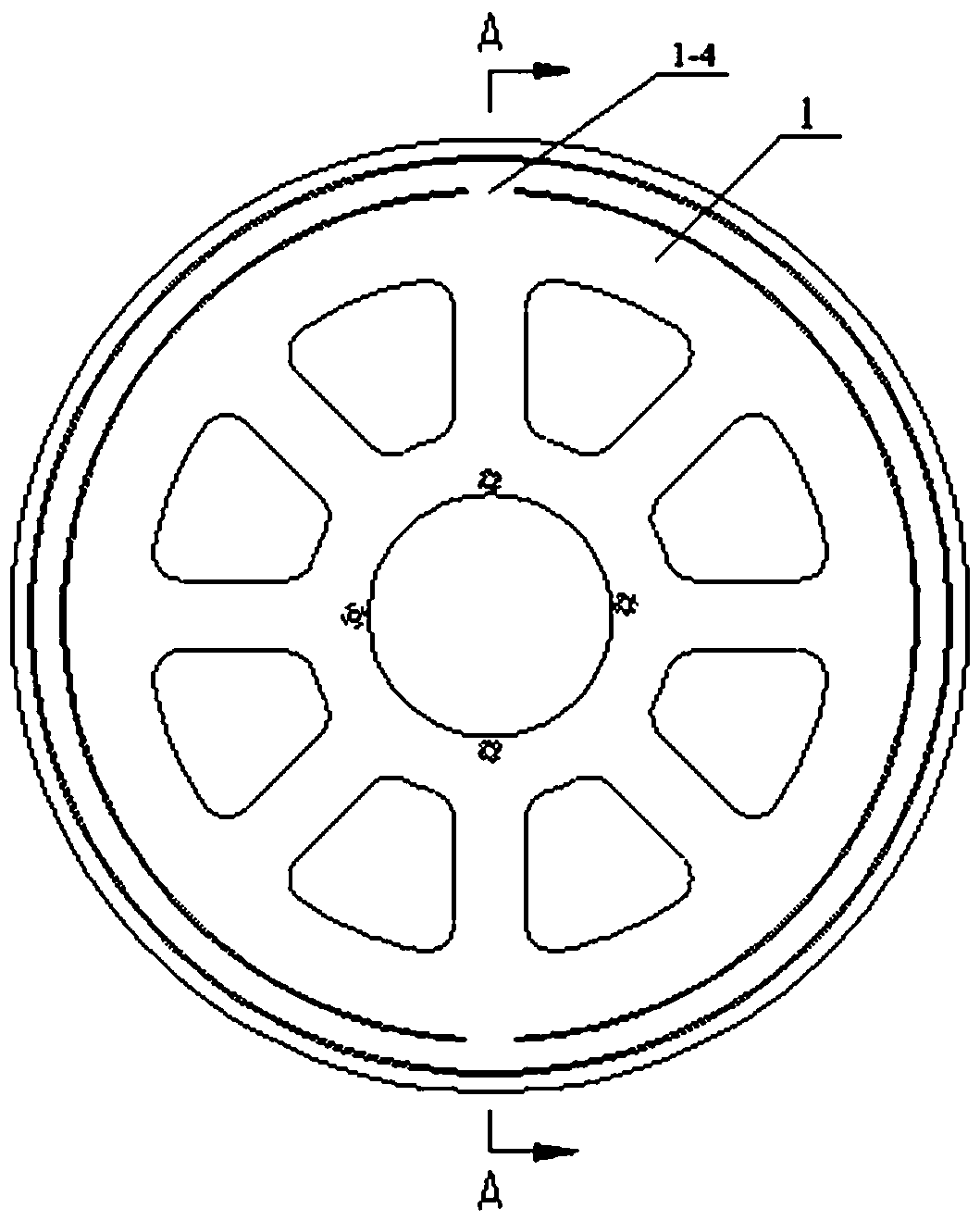

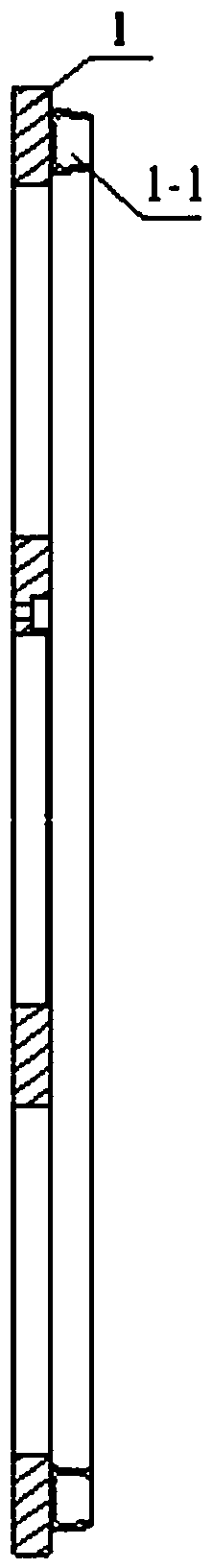

[0019] Referring to the accompanying drawings, a generator rotor structure includes a balance disc 1, the balance disc 1 is arranged between the generator exciter rotor 2 and the non-shaft end bearing 3 and fixed on the generator shaft 4, the balance disc 1 A balance groove 1-1 is provided on the disk 1, and the opening of the balance groove 1-1 faces the non-shaft end bearing 3. According to the needs of dynamic balance, a balance weight 5 is fixed at a matching position in the balance groove 1-1. In order to facilitate on-site adjustment, the outer diameter of the balance plate 1 is larger than the outer circle of the generator rotor. In order to reduce the weight, the balance plate 1 is provided with weight-reducing holes. The cross-section of the groove is a trapezoidal shape with a small outside and a big inside. In order to ensure that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com