Wide flange beam slab plate type rail beam

A technology of slab track and track beam, which is applied to tracks, roads, bridges, etc., can solve the problems of lack of track technology and achieve the effects of clear force transmission, reasonable structure, and reduced bridge deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

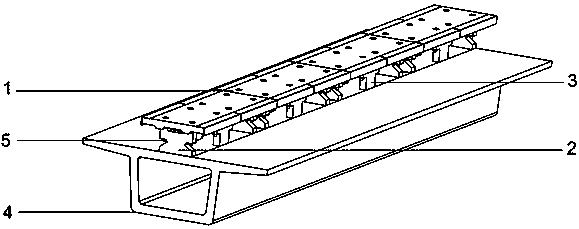

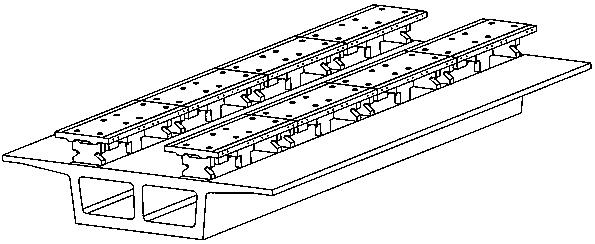

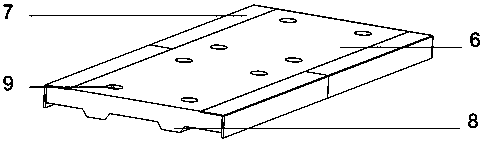

[0025] The slab-on-beam track beam provides a variety of line types. The single-line track on the beam and the multi-line track on the beam can be used. If the load-bearing beam is a multi-line slab track beam structure, the distance between the track slabs must meet the limit requirements. Each line type is composed of upper concrete track slab 1, edge pier column 2, middle pier column 3, lower load-bearing beam 4 and slab pier connection key 5. The upper concrete track slab 1 takes 3.096 meters or other modulus as a system unit, and is manufactured and machined in the factory. The prestressed concrete box girder used by the lower load-bearing beam 4 can adopt a simply supported structure or a continuous str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com