Operation control method and control system for determining trajectory of robot

A technology of operation control and robotics, which is applied in the direction of program control of manipulators, manipulators, manufacturing tools, etc., can solve the problems of difficulty in getting to an accurate position, high technical difficulty, and low efficiency, so as to reduce hysteresis, simplify calculations, Ensure real-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

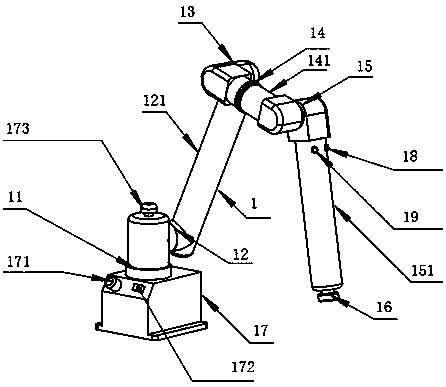

[0080] The multi-axis synchronous manipulator 1 includes a first shaft 11 to a sixth shaft 16, wherein the first shaft 11 is connected to the base 17 in rotation, and the maximum rotation angle is 360°; the second shaft 12 is connected to the first shaft 11 in rotation, The rotation angle of the second shaft 12 is 0~180°; the third shaft 13 is connected to the connecting rod 121 on the second shaft 12 in rotation, and the rotation angle is -90°~180°; one end of the fourth shaft connecting rod 141 is connected to the third shaft 13, the other end is connected to the fifth shaft 15, the fourth shaft connecting rod 141 is divided into two sections of rods, and the two sections of rods are connected in rotation to form the fourth shaft 14, the maximum angle of rotation of which is 360°; the fifth shaft 15 The rotation angle is -90°~90°; the fifth axis connecting rod 151 is connected to the sixth axis 16, and the maximum rotation angle of the sixth axis 16 is 360°. The fifth axis c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com