Rotating shaft oil application device capable of achieving automatic application

A technology for oiling device and rotating shaft, which is applied to the device and coating of the surface coating liquid, which can solve the problems of poor oiling effect of the rotating shaft, improve product production efficiency and product quality, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

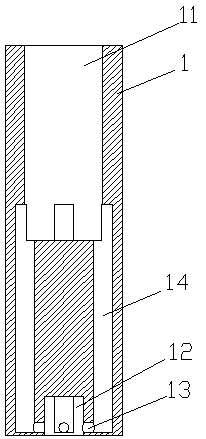

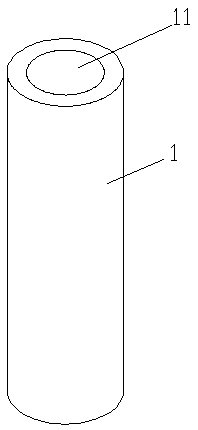

[0016] Such as figure 1 , figure 2 As shown, the present invention proposes a uniformly applied rotating shaft oiling device, comprising: a body 1 with an oil storage chamber 11, the oil storage chamber 11 communicates with a feeding device to supply oil to the oil storage chamber 11, There is also an oiling groove 12 on the body 1, the oiling groove 12 can be inserted into the rotating shaft, and can be used for the rotating shaft to rotate in the oiling groove, the inner wall of the oiling groove is provided with a plurality of oiling holes 13, and the oiling holes 13 pass through the oiling channel 14 communicates with the oil storage chamber 11 to release silicone grease. When the rotating shaft is buckled in, the oil outlet from the oiling hole 13 located on the side wall of the oiling groove 12 can be evenly applied to the movement contact surface on the periphery of the rotating shaft. The rotating shaft can be a connecting rod The rotating shaft with mushroom heads a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com