Additive-free peanut hull preparing device for food processing

An additive-free, food processing technology that is applied in the field of food processing and can solve problems such as waste of resources, mixing of processed shells and peanut kernels, and damage to shells of shelled peanuts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

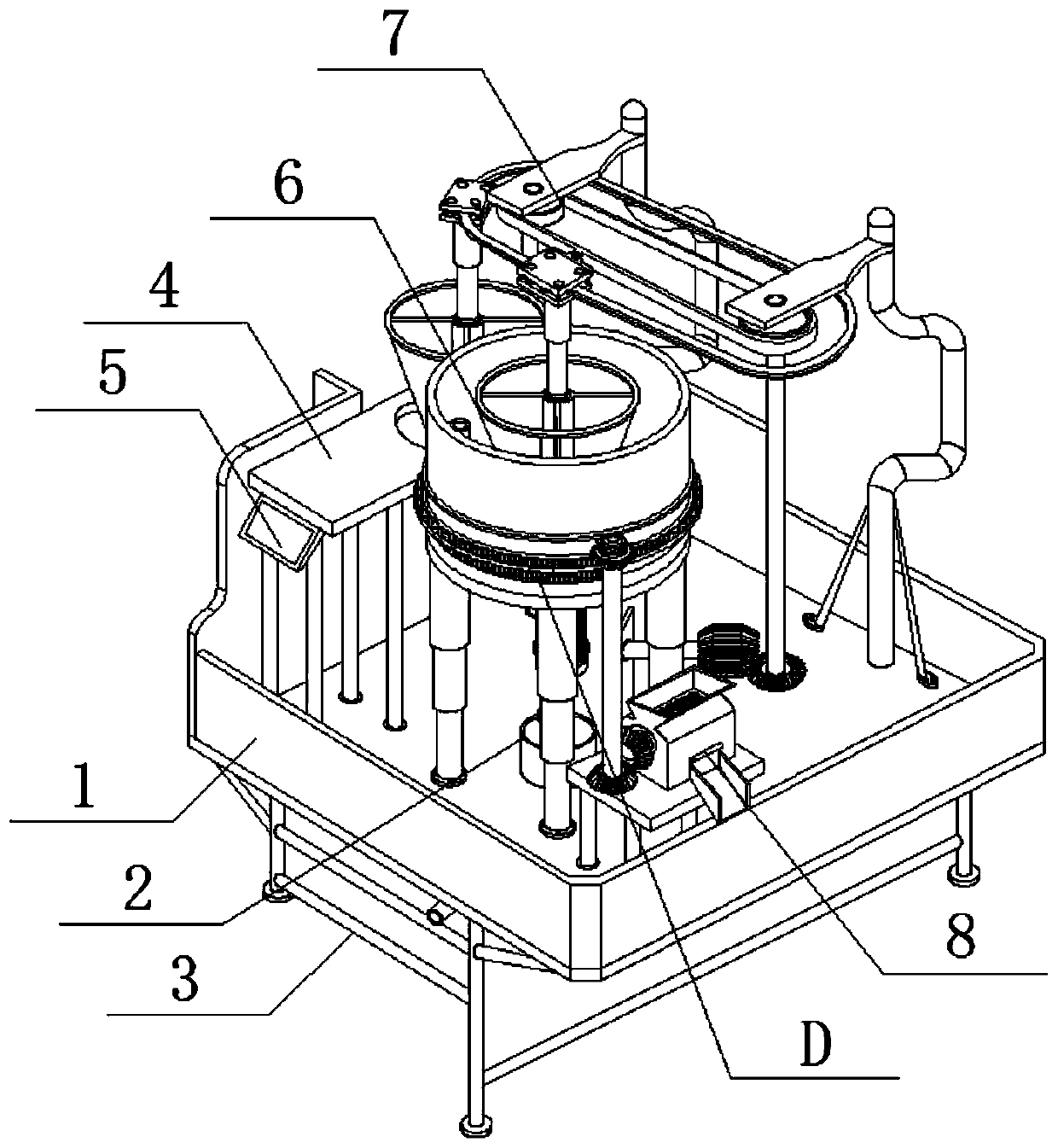

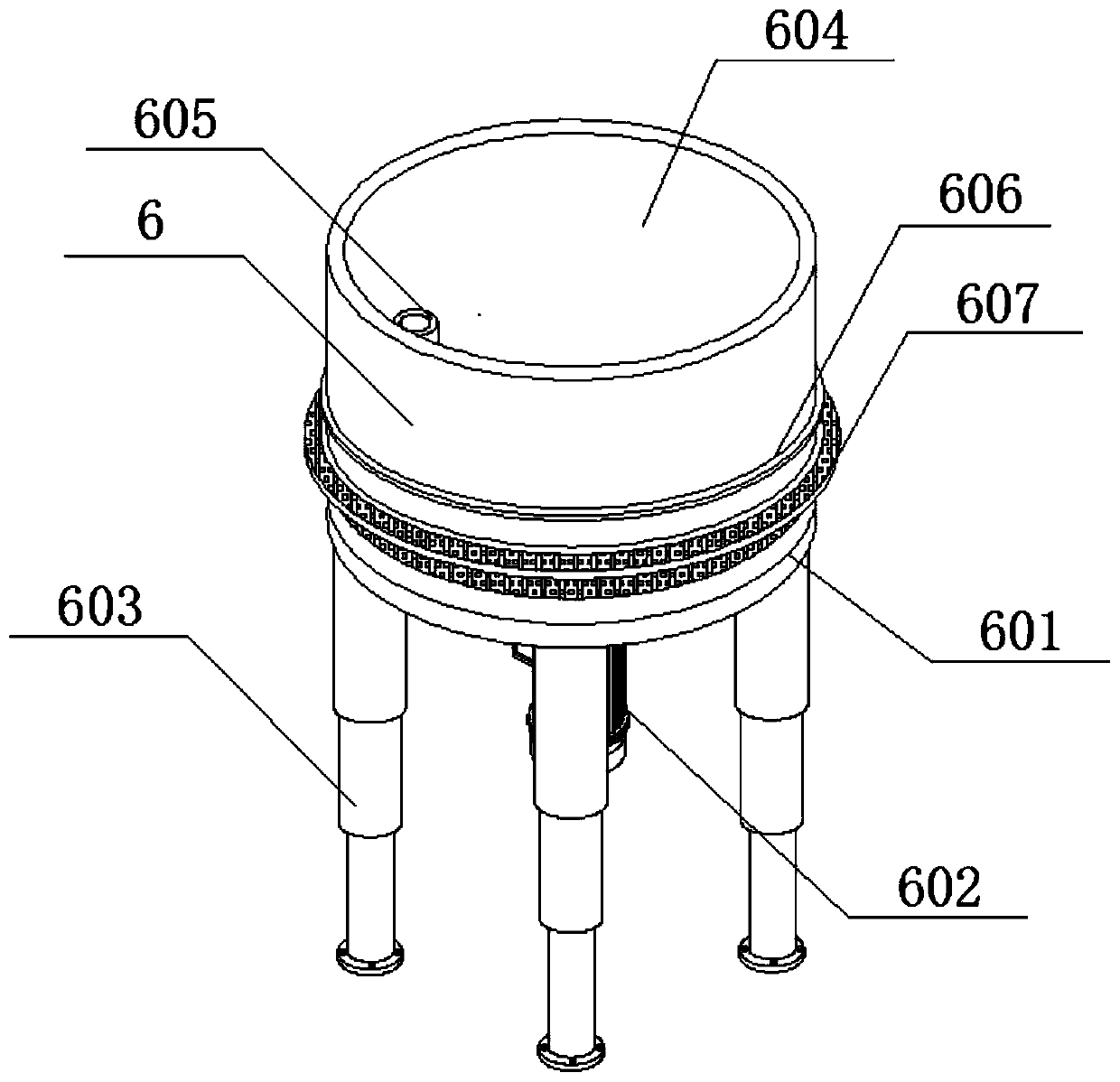

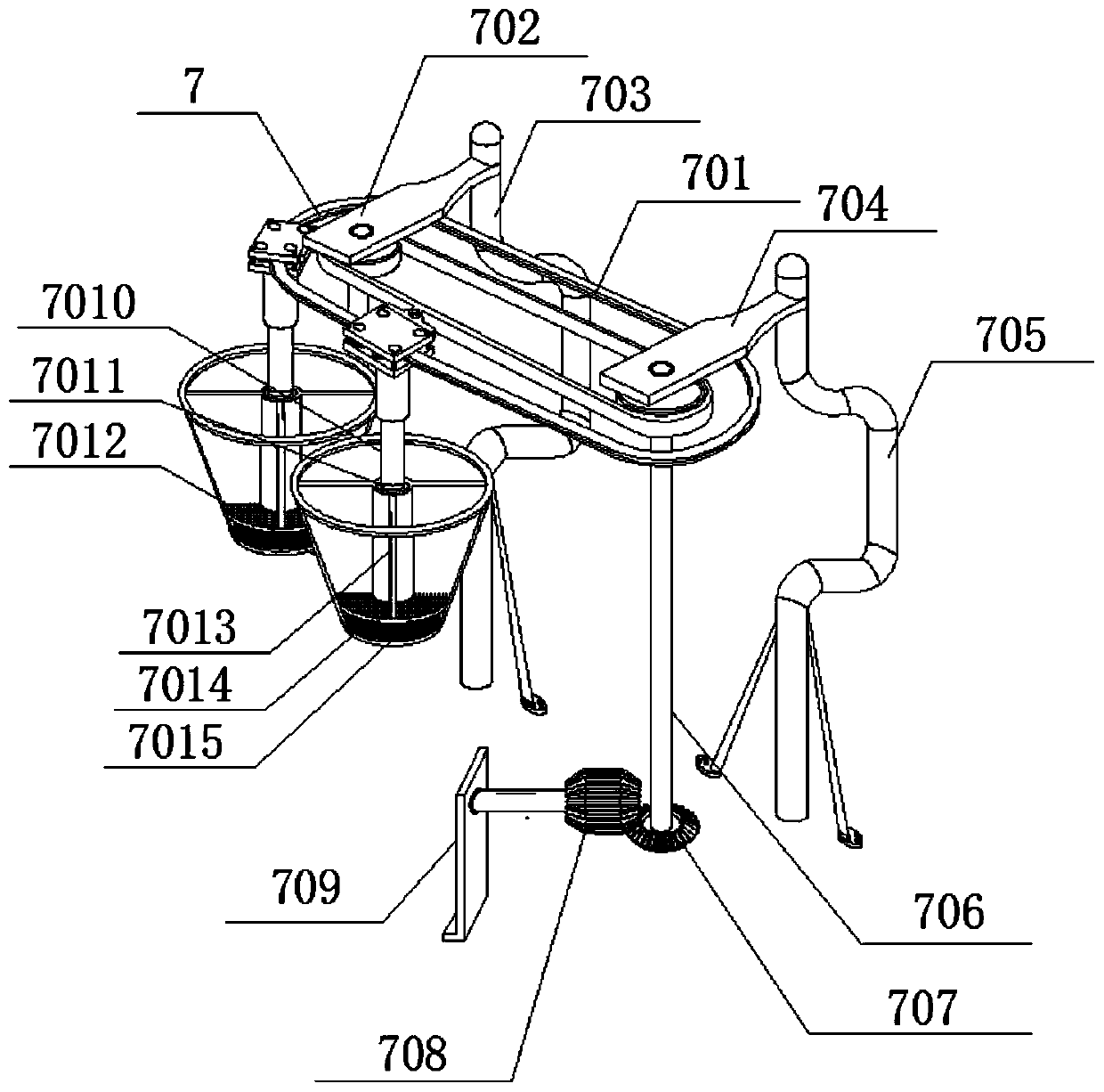

[0025] In this technical solution:

[0026] Passive soaking mechanism-6, sorting mechanism-7, crushing mechanism-8, circular table-601, motor-602, first electric push rod-603, soaking barrel-604, siphon-605, slide rail-606, ring cone Teeth-607, ring guide rail-701, first support plate-702, first support frame-703, second support plate-704, second support frame-705, support shaft-706, first bevel gear-707, the first Second bevel gear-708, first bearing housing-709, second electric push rod-7010, electromagnet-7011, sieve bucket-7012, partition-7013, grading partition-7014, collection partition-7015, The third support plate-801, the support foot-802, the discharge platform-803, the crushing cabin-804, the crushing blade-805, the third bevel gear-806, the fourth bevel gear-807, the connecting rod-808, the fifth Bevel gear-809 and slide block-8010 contain substantial innovative components for the present invention.

[0027] The processing table-1, the ring-2, the base frame-3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com