Method for improving catalytic performance and stability of benzene hydrogenation catalyst

A catalytic performance, catalyst technology, applied in chemical instruments and methods, catalyst activation/preparation, catalysts, etc., can solve the problems of reduced catalyst production time, poor cleaning time, and product quality degradation, etc., to improve and stabilize performance, Simple structure and prolonged production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: a kind of method that improves catalytic performance and stability of benzene hydrogenation catalyst, concrete steps are as follows:

[0026] Saponification reaction of C4-C15 carboxylic acid and sodium hydroxide solution to generate sodium carboxylate salt solution, adding transition metal inorganic salt solution to the sodium carboxylate salt solution for metathesis reaction, adding cyclohexane for extraction to obtain transition metal carboxylate Cyclohexane solution, transition metal carboxylate cyclohexane solution for impurity removal treatment until no free water and emulsified impurities are detected in the upper transition metal carboxylate cyclohexane solution, and then add trihydrocarbyl aluminum solution and alcohols in sequence Complexation reaction to obtain benzene hydrogenation catalyst;

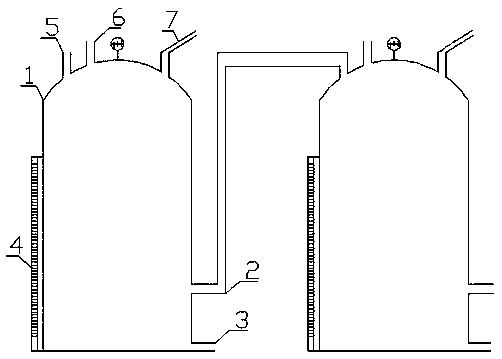

[0027] like figure 1 As shown, the impurity removal equipment is an impurity removal tank 1 arranged in series, the top of the impurity removal tank 1 i...

Embodiment 2

[0033] Embodiment 2: a kind of method that improves catalytic performance and stability of benzene hydrogenation catalyst, concrete steps are as follows:

[0034]Saponification reaction of C4-C15 carboxylic acid and sodium hydroxide solution to generate sodium carboxylate salt solution, adding transition metal inorganic salt solution to the sodium carboxylate salt solution for metathesis reaction, adding cyclohexane for extraction to obtain transition metal carboxylate Cyclohexane solution, transition metal carboxylate cyclohexane solution for impurity removal treatment until no free water and emulsified impurities are detected in the upper transition metal carboxylate cyclohexane solution, and then add trihydrocarbyl aluminum solution and alcohols in sequence Complexation reaction to obtain benzene hydrogenation catalyst;

[0035] like figure 1 As shown, the impurity removal equipment is an impurity removal tank 1 arranged in series, the top of the impurity removal tank 1 is...

Embodiment 3

[0042] Embodiment 3: a kind of method that improves catalytic performance and stability of benzene hydrogenation catalyst, concrete steps are as follows:

[0043] Saponification reaction of C4-C15 carboxylic acid and sodium hydroxide solution to generate sodium carboxylate salt solution, adding transition metal inorganic salt solution to the sodium carboxylate salt solution for metathesis reaction, adding cyclohexane for extraction to obtain transition metal carboxylate Cyclohexane solution, transition metal carboxylate cyclohexane solution for impurity removal treatment until no free water and emulsified impurities are detected in the upper transition metal carboxylate cyclohexane solution, and then add trihydrocarbyl aluminum solution and alcohols in sequence Complexation reaction to obtain benzene hydrogenation catalyst;

[0044] like figure 1 As shown, the impurity removal equipment is an impurity removal tank 1 arranged in series, the top of the impurity removal tank 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com