Pneumatic tire

A technology of pneumatic tires and tires, which is applied in the direction of heavy-duty tires, off-road vehicle tires, tire parts, etc., can solve the problems of groove bottom damage and cut resistance, and achieve the effects of improved traction, sufficient cut resistance, and easy grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

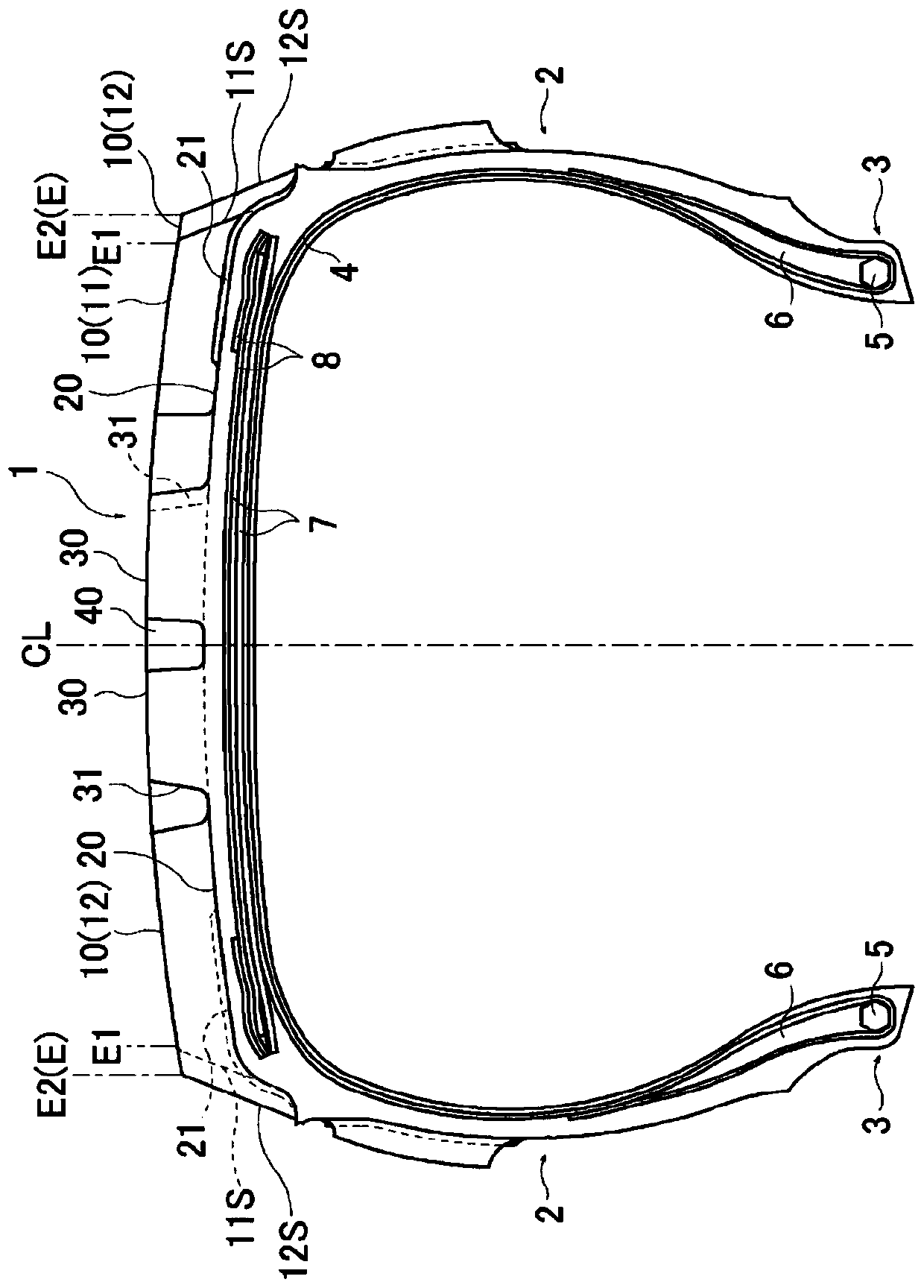

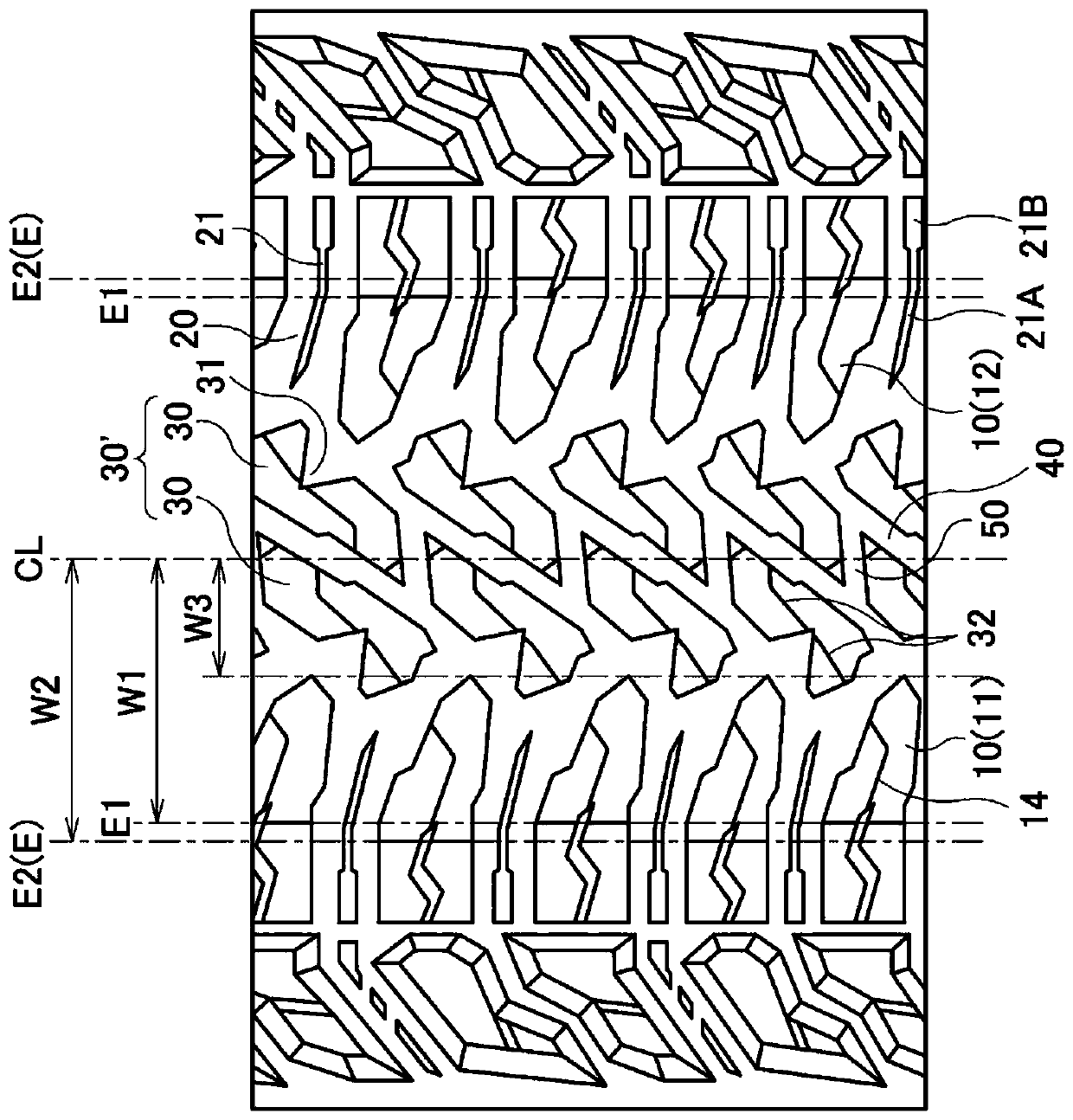

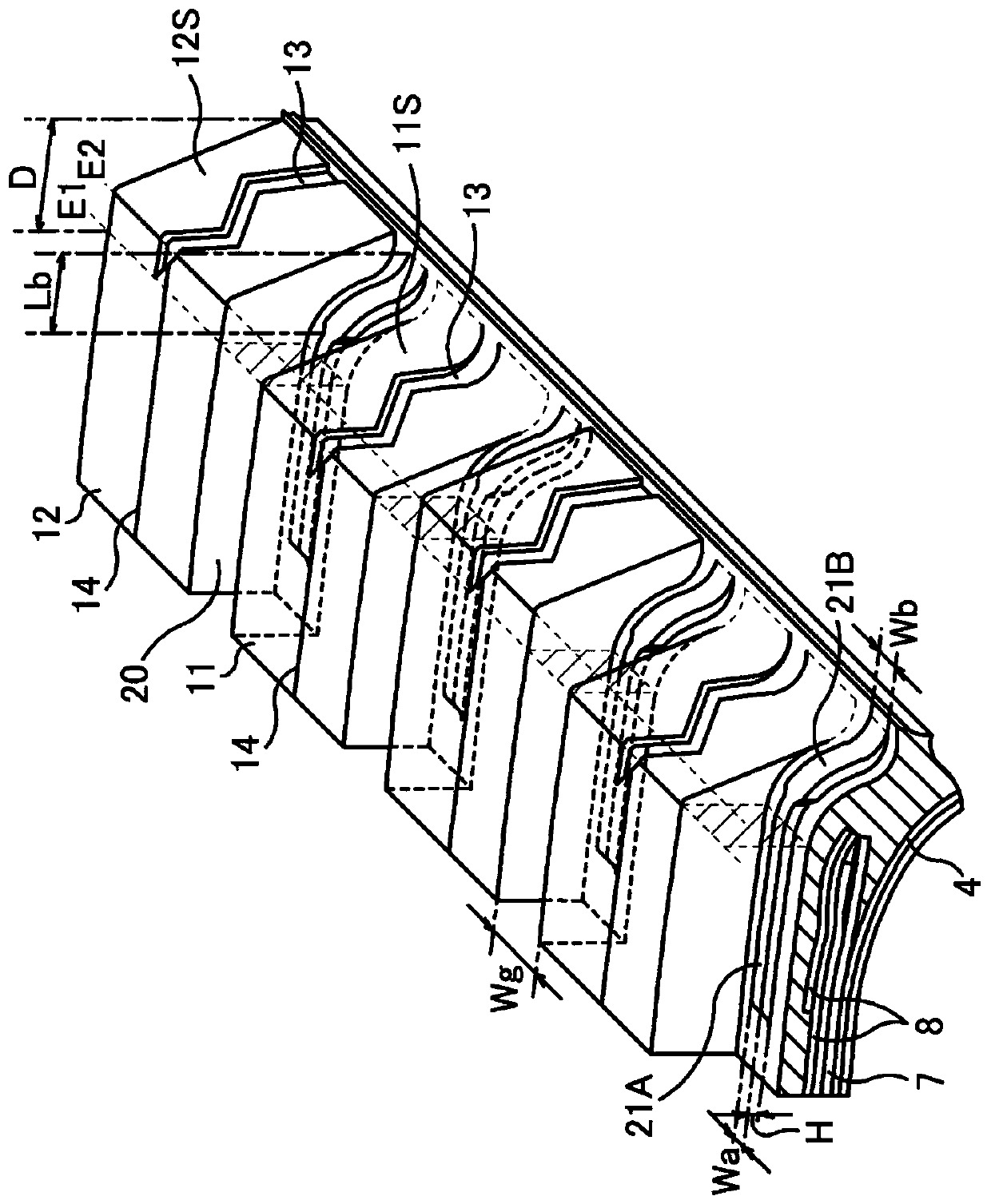

[0039] The tire size is LT265 / 70R17, with figure 1 The illustrated basic structure, with figure 2 Based on the tread pattern of the groove bottom protrusion, the shape of the groove bottom protrusion, the protrusion height H of the groove bottom protrusion, the position of the wide part of the groove bottom protrusion, and the ratio Wb of the protrusion width Wa of the wide width part of the groove bottom protrusion to the protrusion width Wb / Wa, the ratio of the tire width direction length Lb of the wide portion of the groove bottom protrusion to the distance D from the tire width direction outer end of the inner block to the end end of the outer block (Lb / D×100%), from the tire equator to The ratio of the distance W1 of the outer end in the tire width direction of the inner block to the distance W2 from the tire equator to the outer end of the outer block in the tire width direction (W1 / W2×100%) and the shape of the shallow groove are set as shown in Tables 1 and 2, respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com