Online ultrasonic detection device and method for internal defect expanding of turbine engine rotor

A technology of turbine engine and ultrasonic testing, which is applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the problems of low efficiency and poor effect of non-destructive testing High search efficiency, strong recognition ability, and efficient recognition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

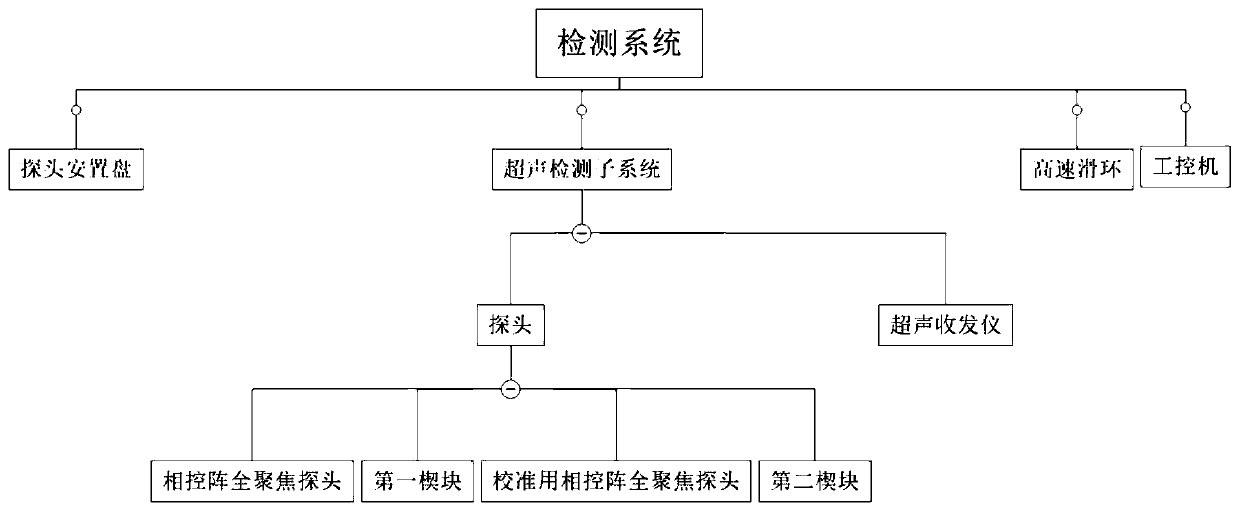

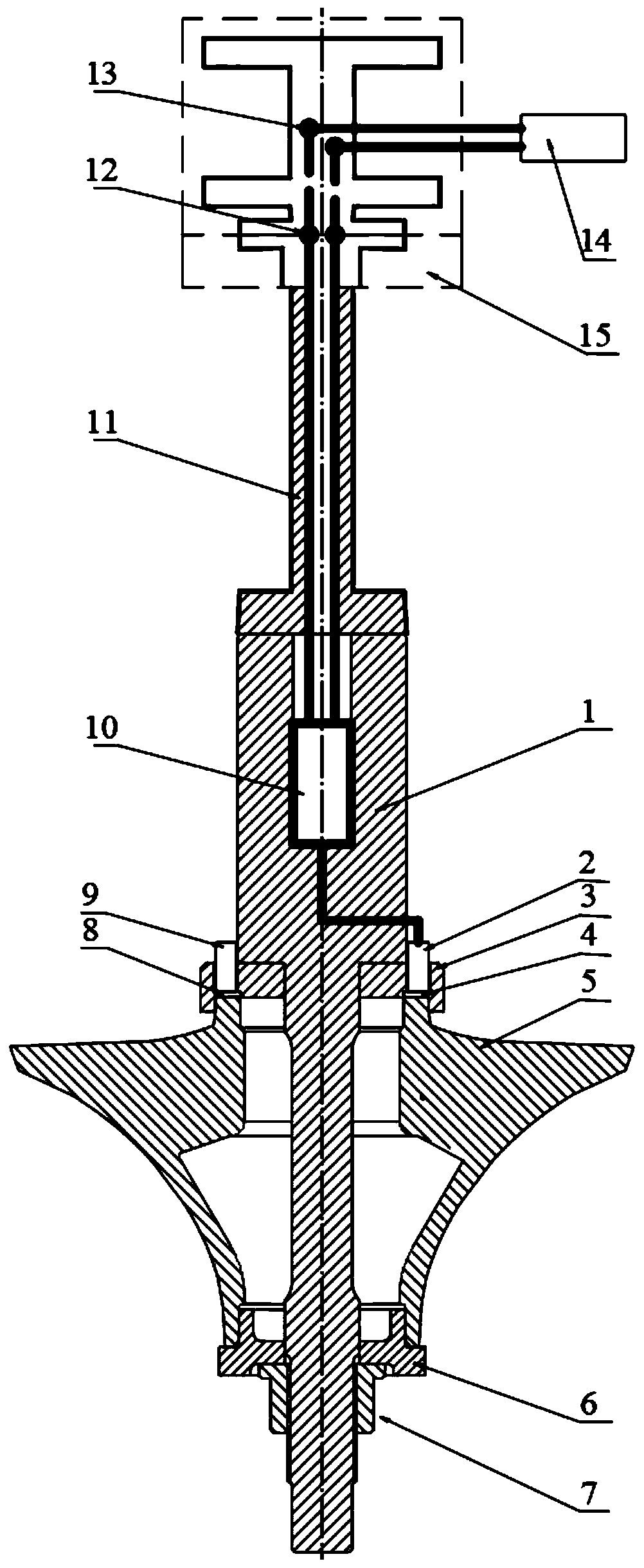

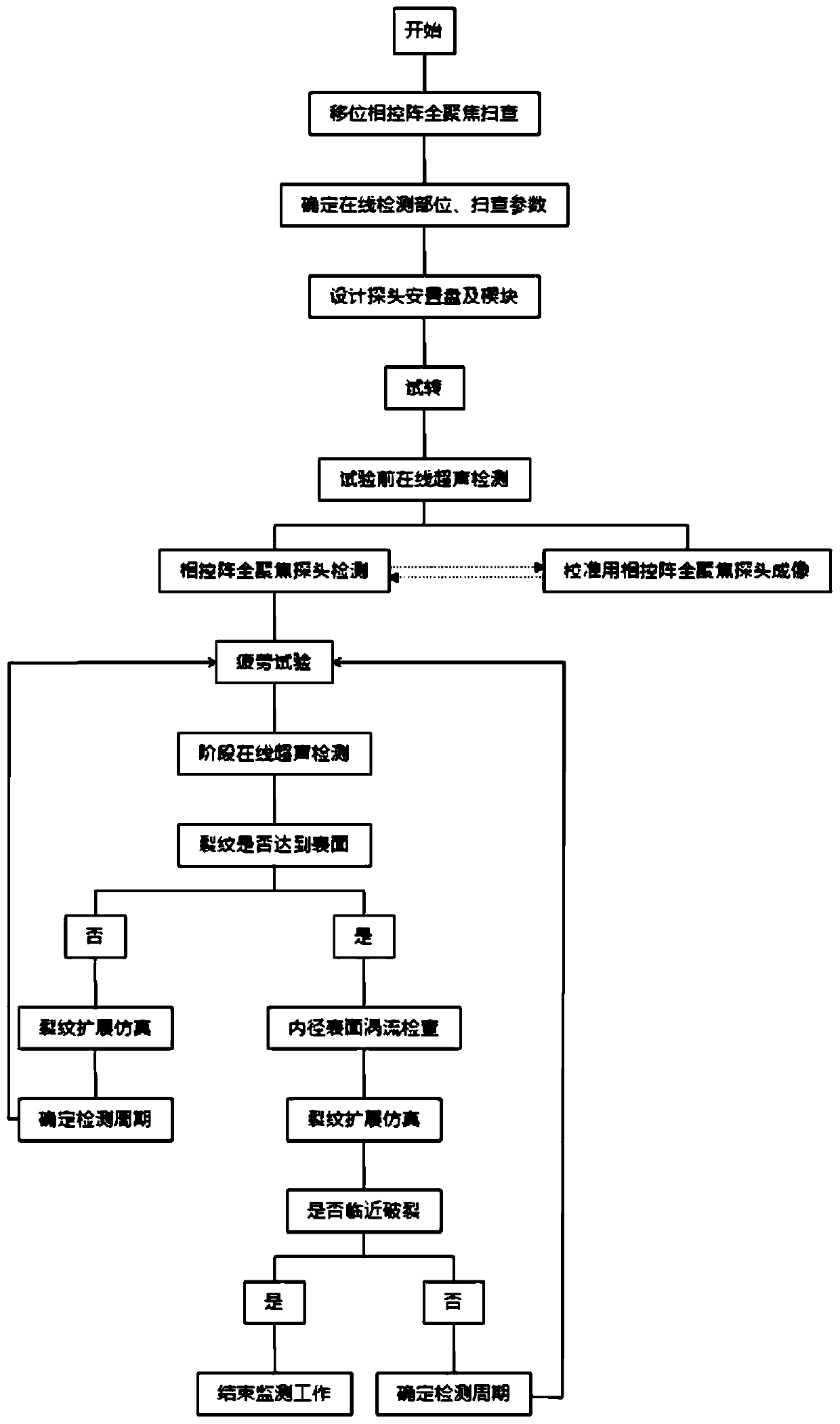

[0030] Such as figure 1 As shown, the on-line ultrasonic testing device for internal defect expansion of the turbine engine rotor includes a mandrel 1, a high-speed flexible shaft 11, a probe placement cover 3, an ultrasonic testing subsystem, a high-speed slip ring 15, and an industrial computer 14; the ultrasonic testing subsystem includes a phased array An all-focus probe 2 and an ultrasonic transceiver 10; the turbine engine rotor 5 to be tested is installed on the mandrel, one end is fastened by a lock nut 7, and the other end is fixed by a probe placement cover 3; the probe placement cover has a second A bolt hole, the phased array full-focus probe 2 is placed in the first bolt hole; the first bolt hole is provided with a first groove near the end of the turbine engine rotor 5, and the first wedge 4 is placed in the first groove; The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com