A Combined Suction Anchor Reinforced by Grouting Spiral Anchor

A suction anchor and screw anchor technology, which is applied in construction, infrastructure engineering, sheet pile wall and other directions, can solve the problems of difficult bearing capacity, weak integrity, and little effect of skirt structure bearing capacity, so as to improve the Tensile bearing capacity, the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

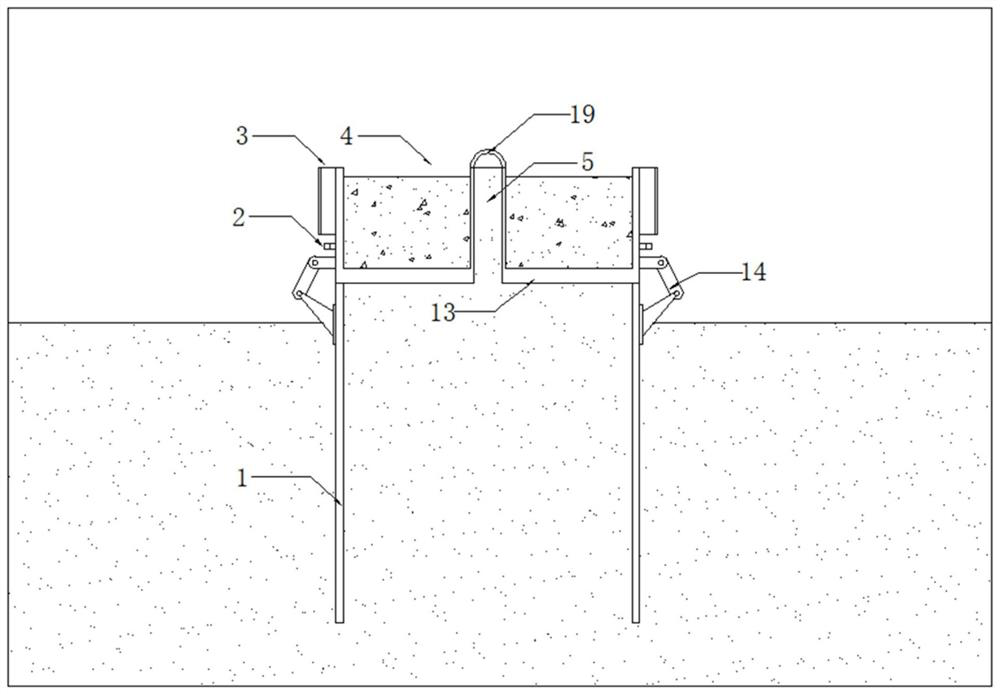

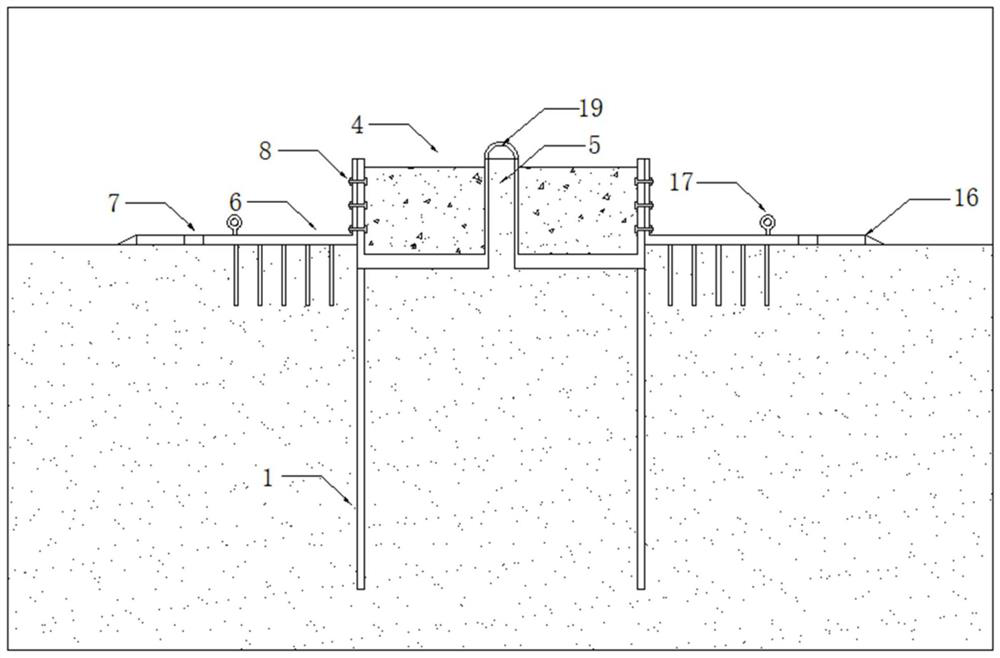

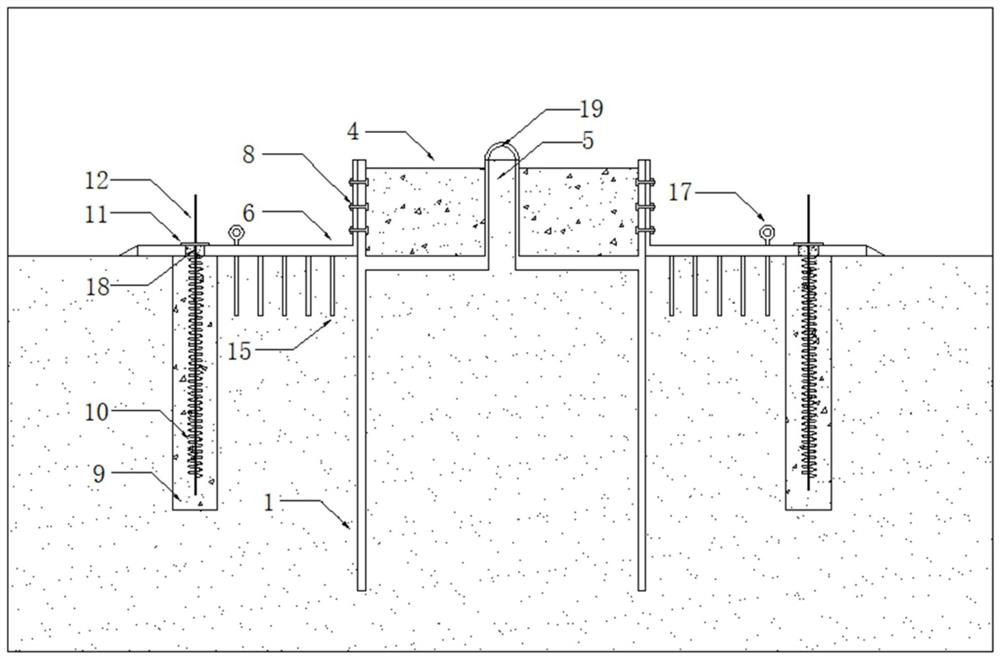

[0040]Specific, such asFigure 1-5As shown, a specific implementation example is as follows:

[0041]The entire installation process of the suction anchor device is divided into three stages: the first stage, the suction anchor device is installed by its own weight and the suction is installed to a specified depth; the second stage, the L-shaped skirt 6 and the suction anchor are fixedly connected by high-strength bolts 8; In the third stage, the screw bolt 12 is installed and grouted to form a reinforced area for pulling resistance.

[0042]In the first stage of the installation of the suction anchor, penetrating installation is carried out through the weight of the suction anchor and the concrete compact 4. At the same time, the steel cable that suspends the lifting lug 2 vertically passes through the vertical channel 3 during the installation process to ensure that the suction anchor always remains vertical during the installation process. Then apply negative pressure through the suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com