Vehicle door safety loop line fault point detection system and fault judging method

A safety loop and detection system technology, applied in railway signal and safety, door/window accessories, railway car body parts, etc., can solve problems such as difficult to determine the fault location, unable to eliminate the fault as soon as possible, safety loop fault between doors, etc., to achieve The effect of reducing operation and maintenance costs, facilitating operation and maintenance, and reducing the difficulty of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] While the invention may be embodied in various forms, some exemplary and non-limiting embodiments are shown in the drawings and will be described below, it should be understood that the disclosure is to be considered as an example of the invention and not It is intended that the invention be limited to the specific embodiments described.

[0044] In different figures, functionally identical parts have the same reference numerals, so these parts are usually only described once.

[0045] The present invention proposes a fault point detection system of the door safety loop, which can accurately locate the fault point monitoring system and fault judgment method of the door safety loop, thereby reducing the risk of train delays, off-lines, or even clearing passengers due to faults in the door safety loop , and at the same time reduce the difficulty of door safety loop troubleshooting, reduce operation and maintenance costs, and improve operational efficiency.

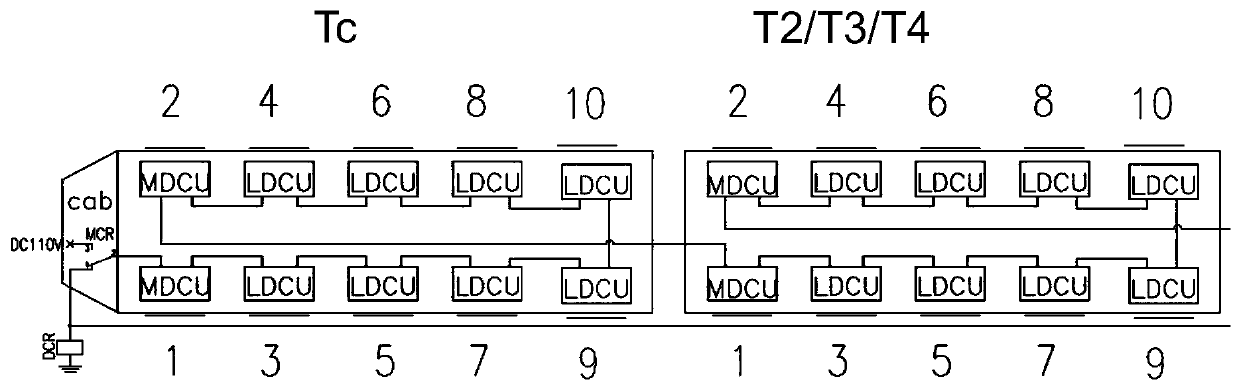

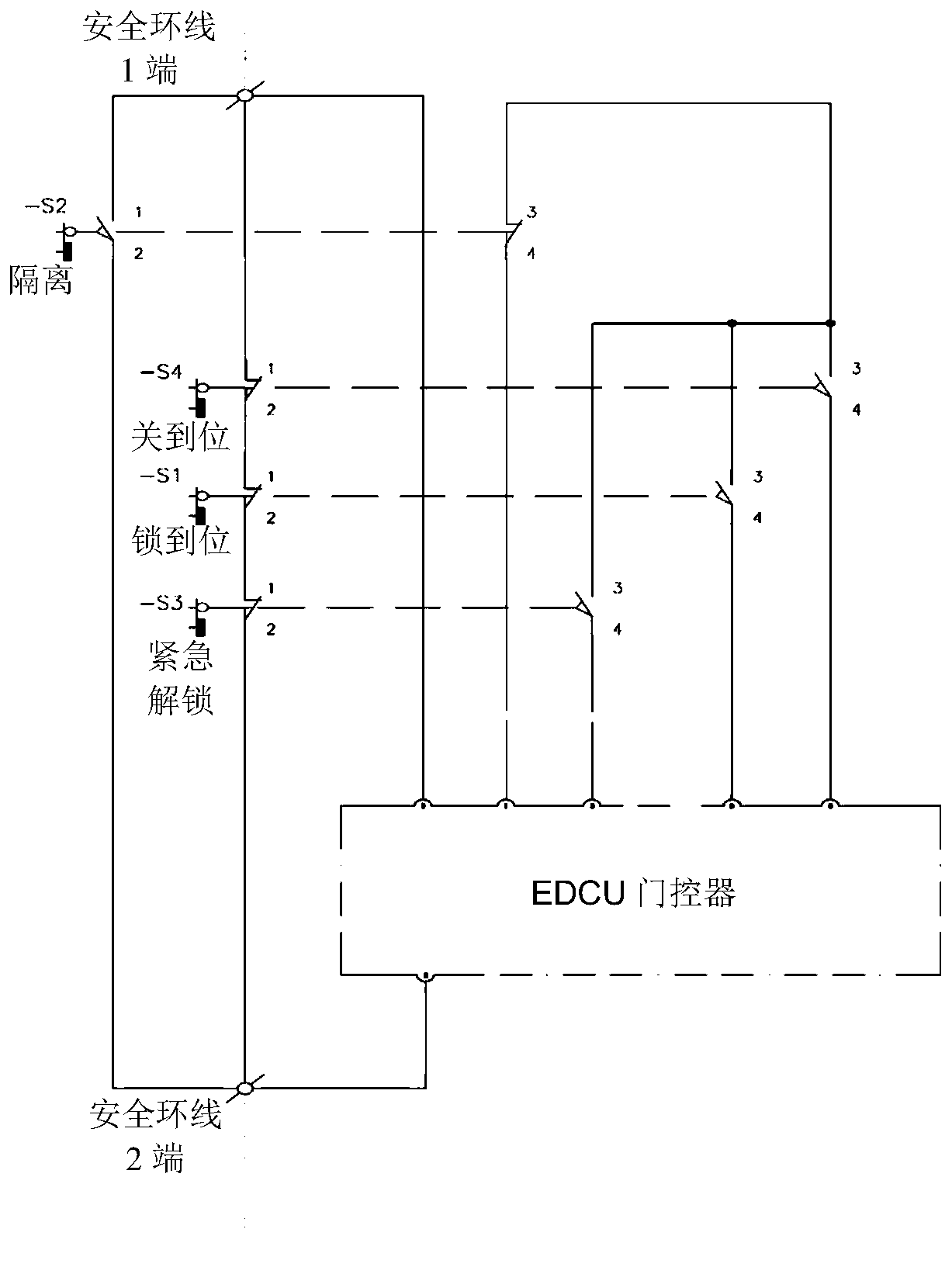

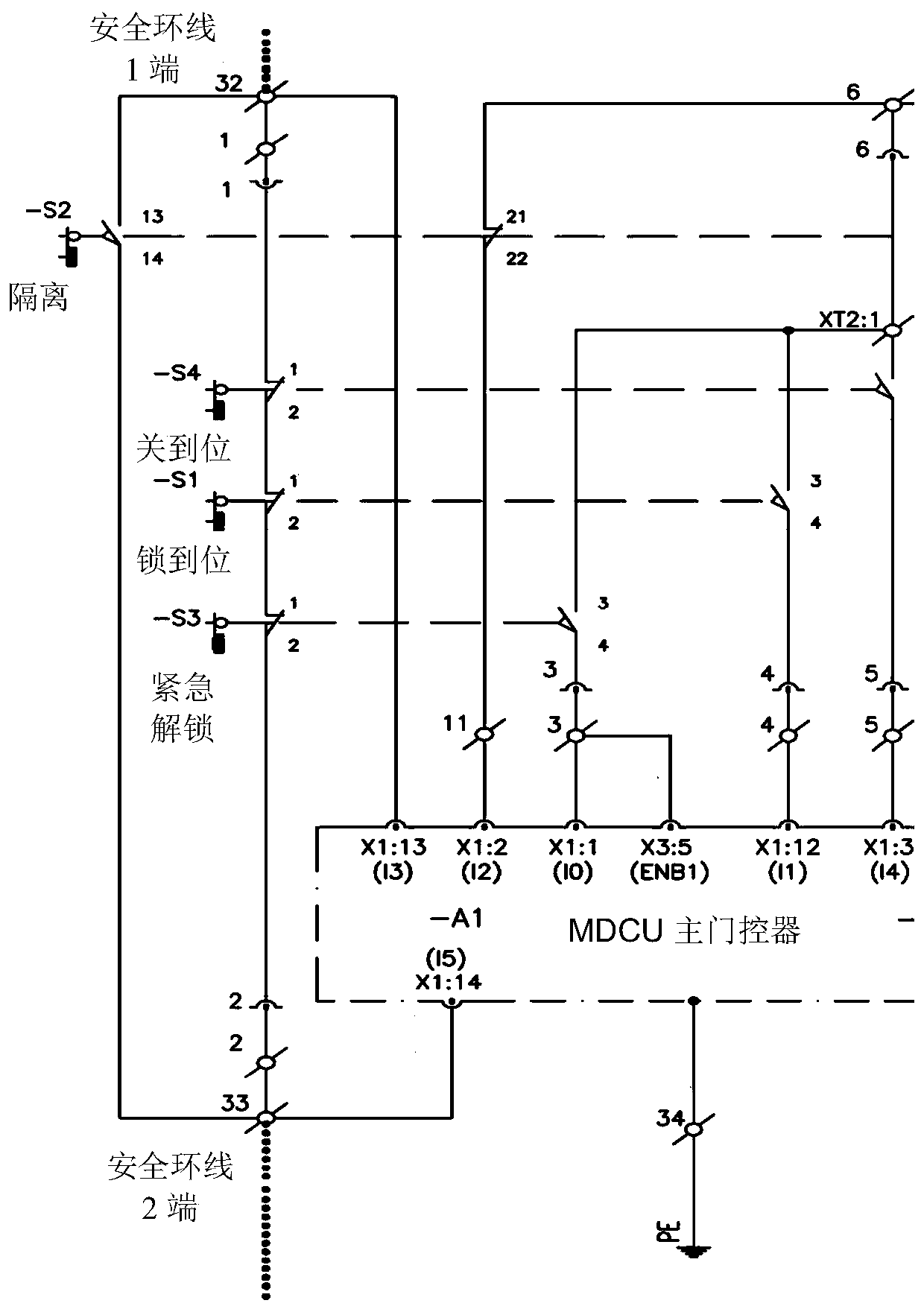

[0046] figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com