Skin piece perforating device

A technology for hole-making devices and skin parts, which is applied in the direction of manufacturing tools, boring/drilling, drilling/drilling equipment, etc. Low position accuracy and other issues, to achieve the effect of improved efficiency, convenient adjustment, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

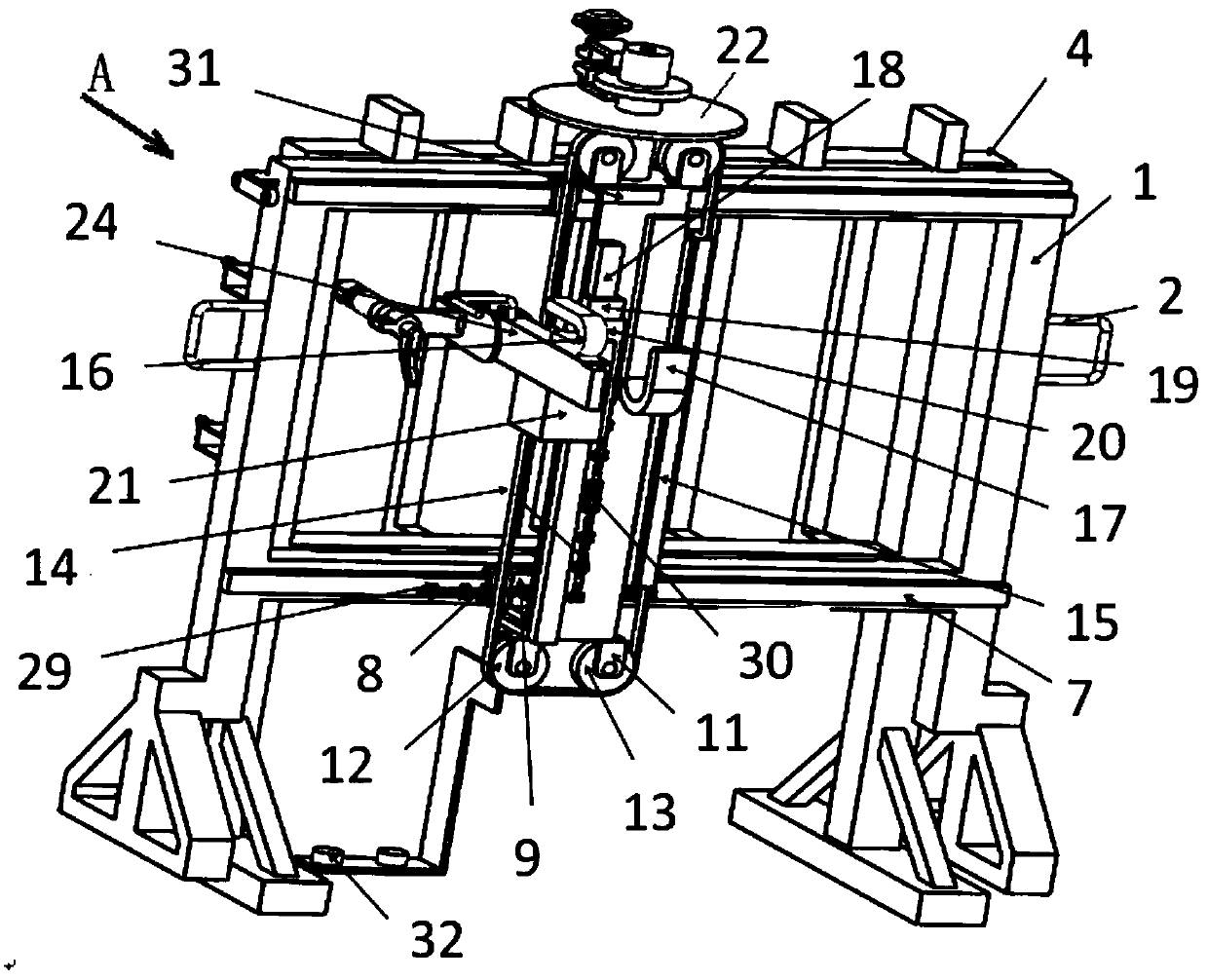

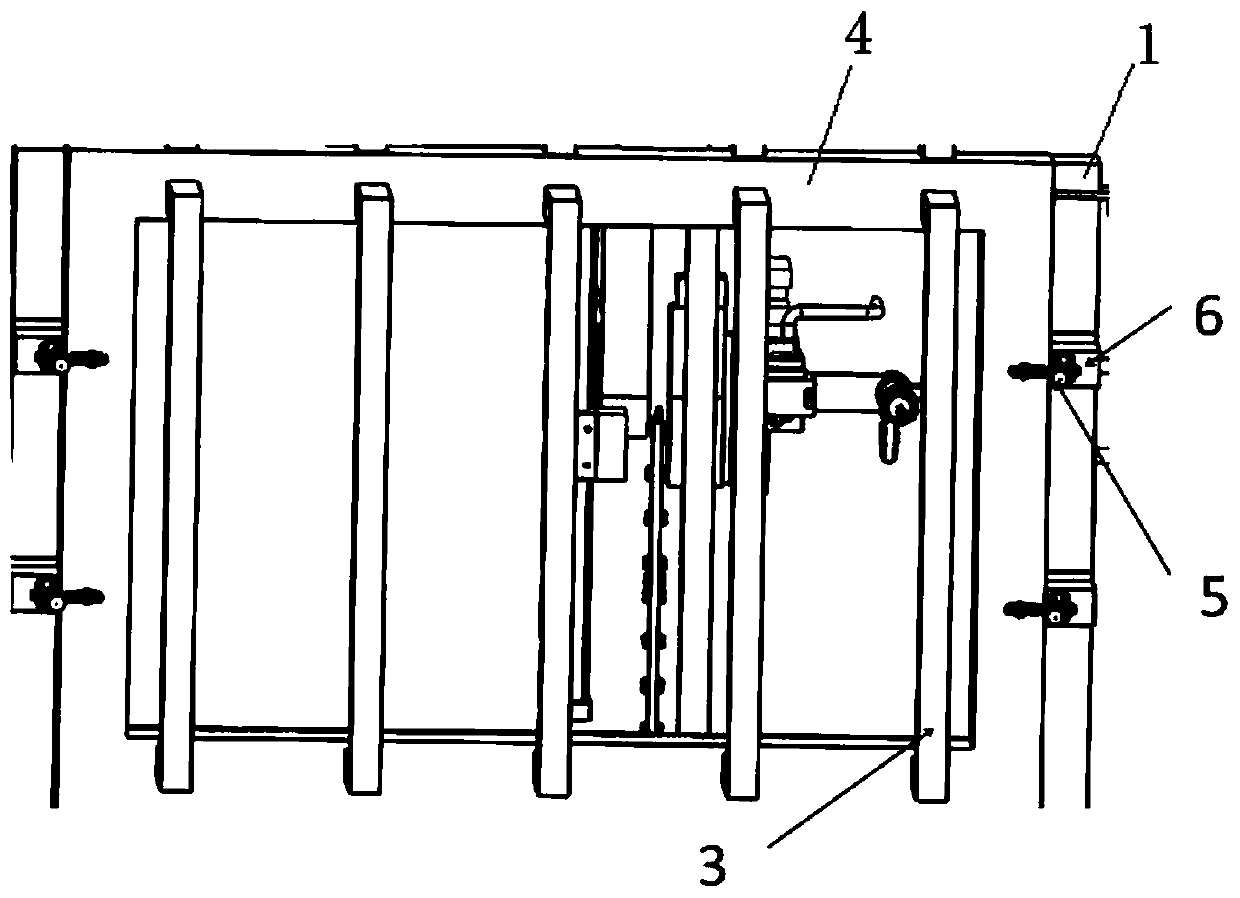

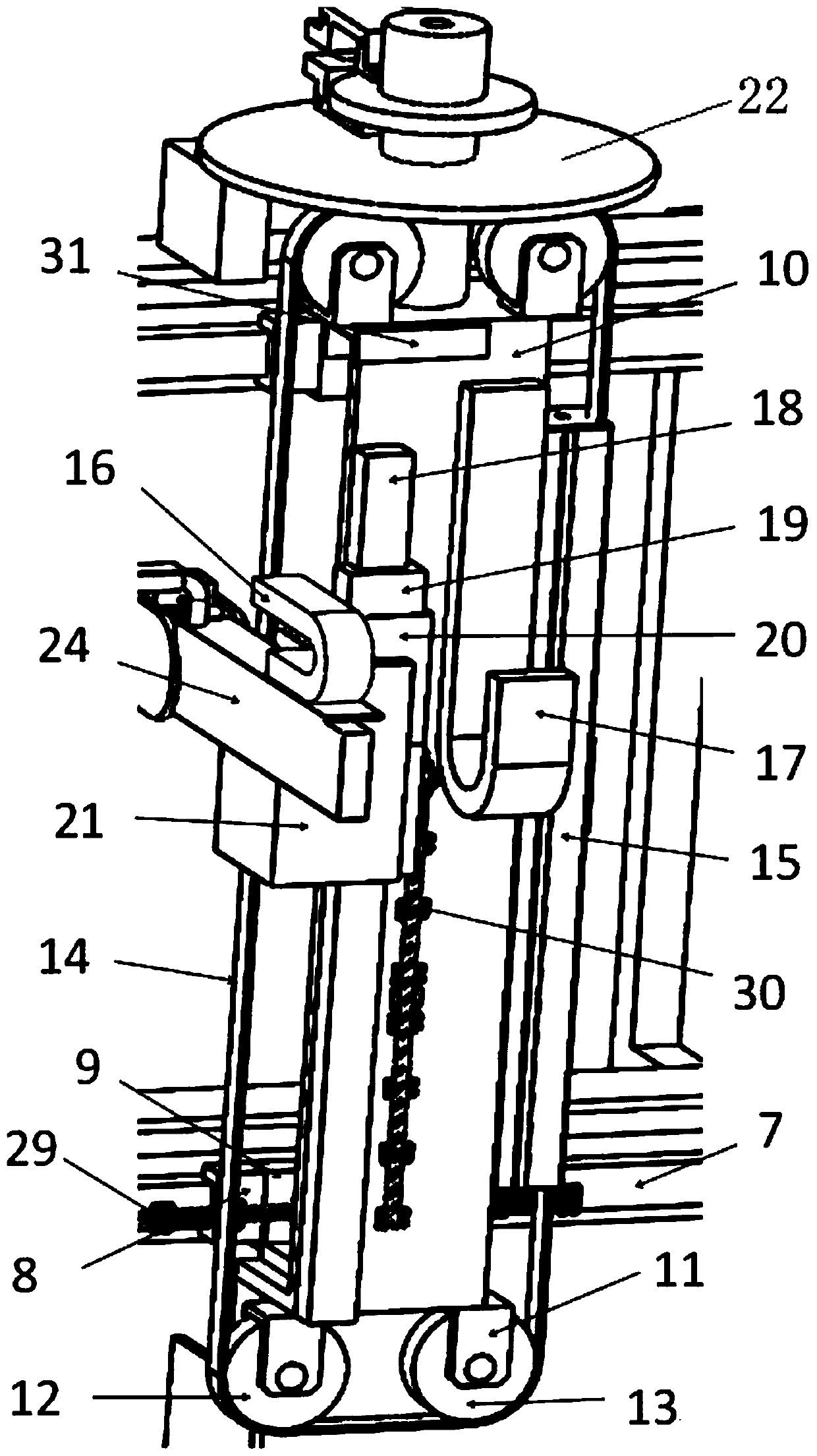

[0045] The skin part hole-making device described in this embodiment is used for processing a certain skin part. The counterweight wheel frame weighs 16Kg, its material is LY12, and its thickness is 2mm.

[0046] In this embodiment, the hole diameter of the skin is 4.2 mm, the number of holes is 80, and the holes are distributed in 4 rows and 8 columns.

[0047] The rodless cylinder adopts the balance cylinder of SMC series, and its cylinder diameter is 30mm. The models of tensioning timing belt and timing pulley are MBQ and FTPA-MXL respectively. The horizontal guide rail and the vertical guide rail adopt HIWIN series linear guide rail respectively, the model is SSVRB.

[0048] In this embodiment, the entire hole-making process is successfully completed by using the skin-piece hole-making device of the present invention, which is easy to operate and can meet the requirements for flexible hole-making at multiple angles such as obliquely upward and obliquely downward.

Embodiment 2

[0050] The skin part hole-making device described in this embodiment is used to process a certain skin part. The counterweight wheel frame weighs 18Kg, the material is LC4, and the thickness is 3mm.

[0051] In this embodiment, the hole diameter of the skin is 5 mm, the number of holes is 120, and the holes are distributed in 6 rows and 20 columns.

[0052] The rodless cylinder adopts the balance cylinder of SMC series, and its cylinder diameter is 30mm. The models of tensioning timing belt and timing pulley are MBQ and FTPA-MXL respectively. The horizontal guide rail and the vertical guide rail adopt HIWIN series linear guide rail respectively, the model is SSVRB.

[0053] In this embodiment, the whole hole-making process is successfully completed by using the skin-piece hole-making device of the present invention, which is easy to operate and can meet the requirement for lamination of aluminum alloy and skin-piece for hole-making.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com