Precoated sand shell mold casting technology

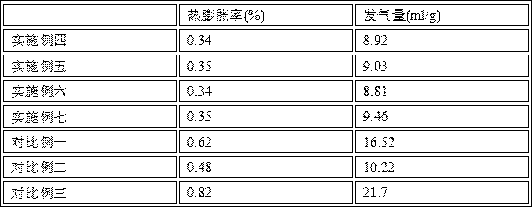

A technology of shell casting and coated sand, which is used in manufacturing tools, casting molding equipment, casting molds, etc., can solve problems such as workers' health hazards, and achieve the effects of low thermal expansion rate, excellent heat resistance, and low gas generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

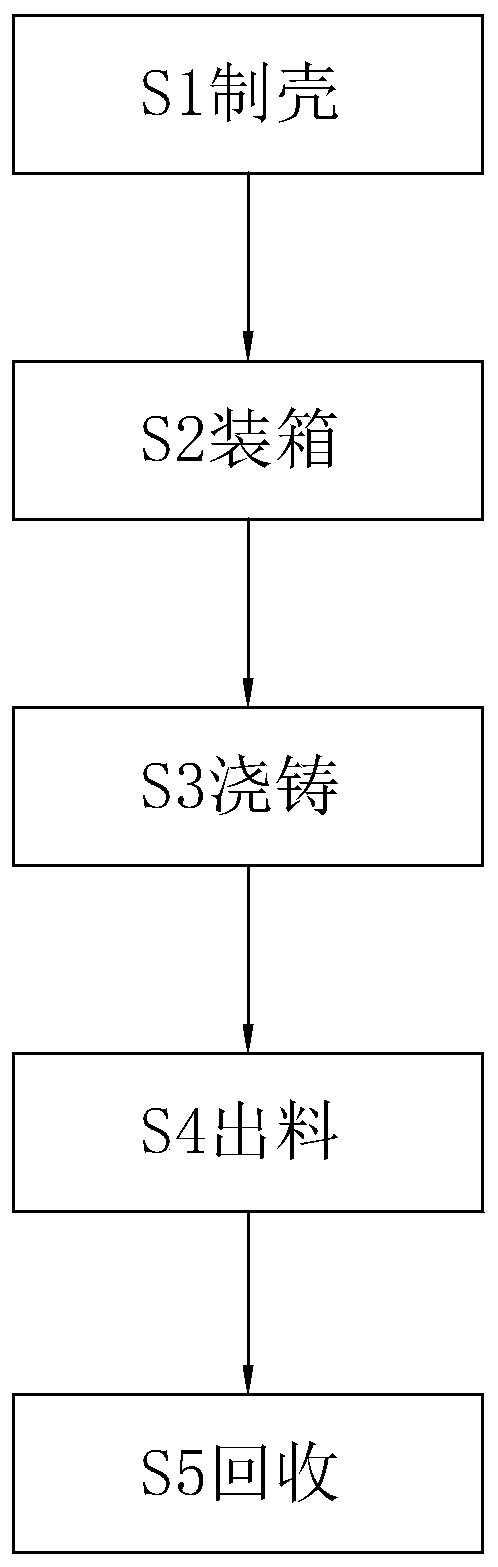

[0047] S1 shell making: configure the coated sand and make the metal template required by the corresponding casting, then use the sand shooting machine to cover the coated sand on the metal template, heat the metal template to 180°C, and the coated sand hardens to make the upper shell and Lower shell type, bonding the upper shell type and the lower shell type together to form a complete shell type;

[0048] S2 packing: Put the shell into the box, then fill the steel shot between the outside of the shell and the inner wall of the box and vibrate;

[0049] S3 Casting: Pour molten iron into the inner cavity of the shell mold, blow it to cool after pouring, and the casting is formed;

[0050] S4 Discharging: Pour out the castings, waste sand, and steel shots in the box together, separate the castings with a shakeout machine, clean and inspect the surface of the castings, and put them into storage after passing the test;

[0051] S5 Recycling: Magnetic separation to separate waste...

Embodiment 2

[0053] S1 shell making: configure the coated sand and make the metal template required by the corresponding casting, then use the sand shooting machine to cover the coated sand on the metal template, heat the metal template to 280°C, and the coated sand hardens to make the upper shell and Lower shell type, bonding the upper shell type and the lower shell type together to form a complete shell type;

[0054] S2 packing: Put the shell into the box, then fill the steel shot between the outside of the shell and the inner wall of the box and vibrate;

[0055] S3 Casting: Pour molten iron into the inner cavity of the shell mold, blow it to cool after pouring, and the casting is formed;

[0056] S4 Discharging: Pour out the castings, waste sand, and steel shots in the box together, separate the castings with a shakeout machine, clean and inspect the surface of the castings, and put them into storage after passing the test;

[0057] S5 Recycling: Magnetic separation to separate waste...

Embodiment 3

[0059] S1 shell making: configure the coated sand and make the metal template required by the corresponding casting, then use the sand shooting machine to cover the coated sand on the metal template, heat the metal template to 230°C, and the coated sand hardens to make the upper shell and Lower shell type, bonding the upper shell type and the lower shell type together to form a complete shell type;

[0060] S2 packing: Put the shell into the box, then fill the steel shot between the outside of the shell and the inner wall of the box and vibrate;

[0061] S3 Casting: Pour molten iron into the inner cavity of the shell mold, blow it to cool after pouring, and the casting is formed;

[0062] S4 Discharging: Pour out the castings, waste sand, and steel shots in the box together, separate the castings with a shakeout machine, clean and inspect the surface of the castings, and put them into storage after passing the test;

[0063]S5 Recycling: Magnetic separation to separate waste ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com