Wear-resistant straightening machine for steel rib processing

A technology of steel bar processing and straightening machine, which is applied in the field of steel bar processing, can solve the problems of poor adjustability of the device and large limitation of steel bar straightening, and achieves good effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

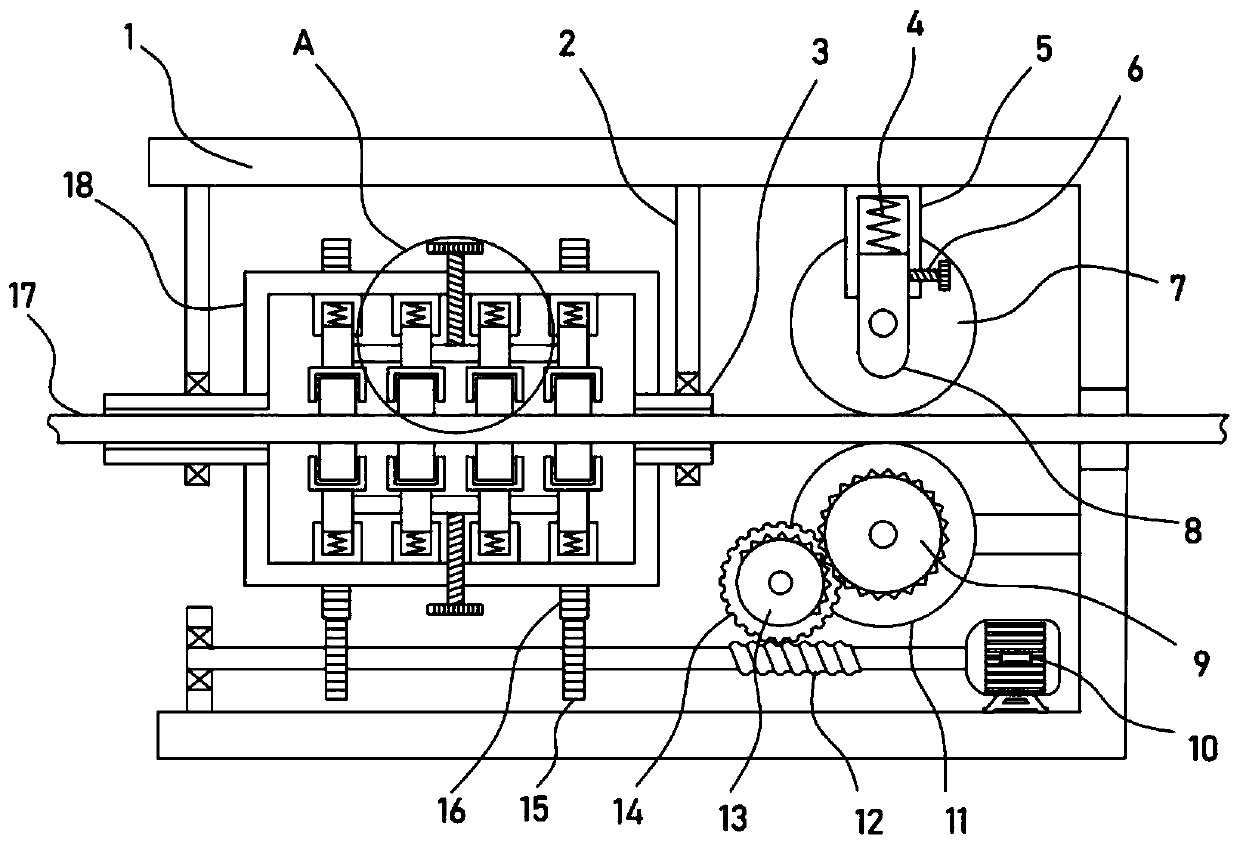

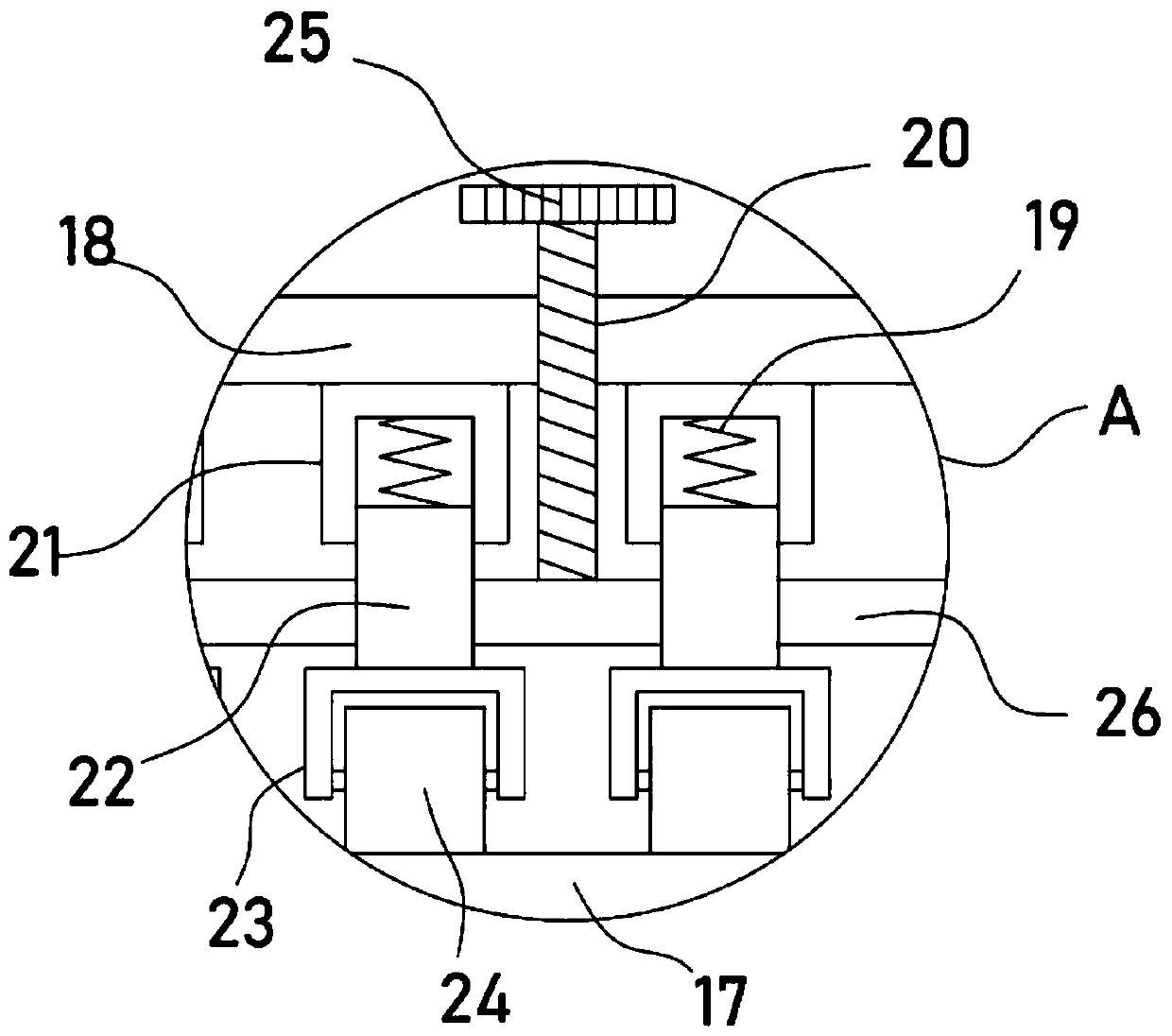

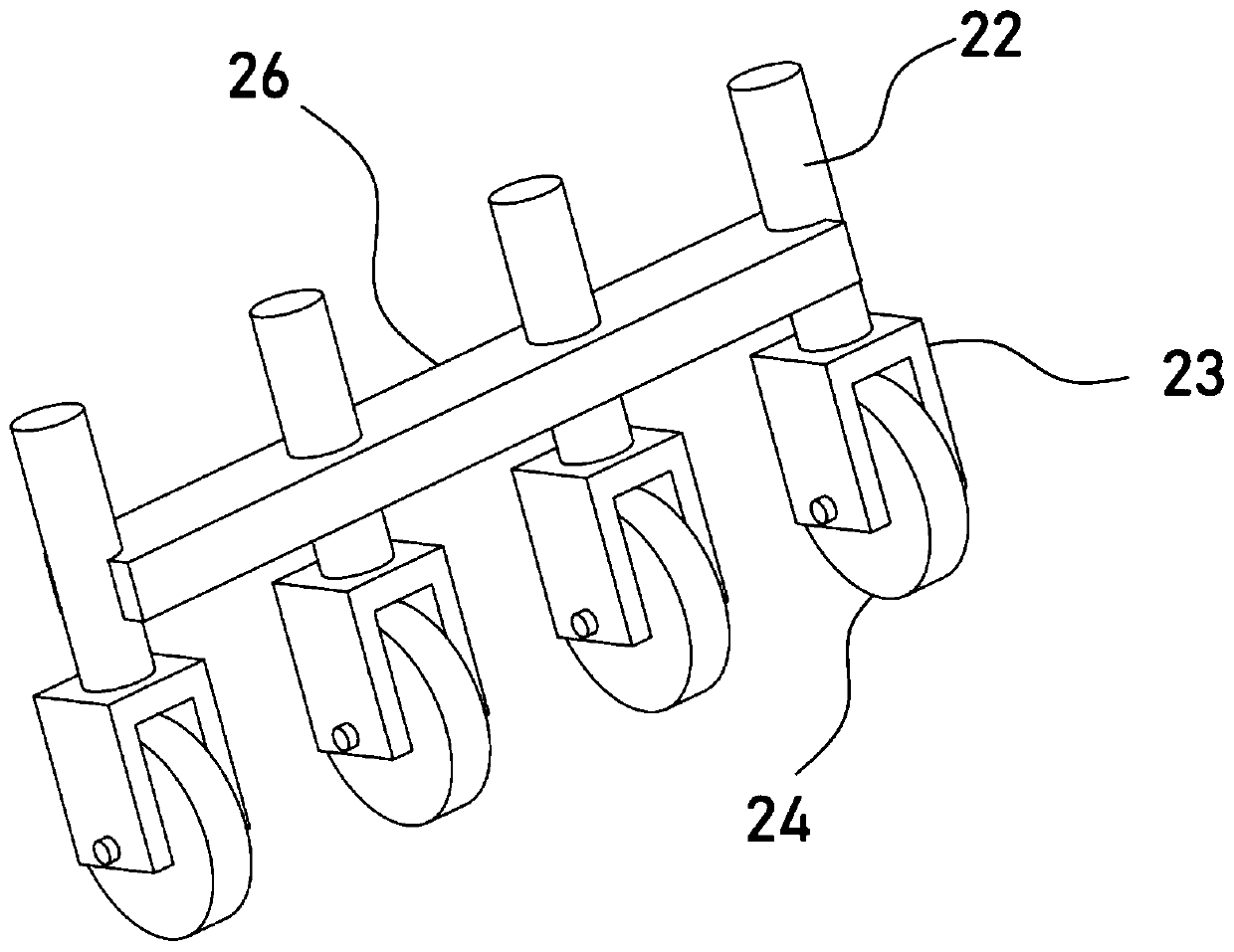

[0022] see Figure 1-4 , a steel bar processing wear-resistant straightening machine, including a frame 1, the frame 1 is provided with a driven roller 7 for pressing a steel bar 17, and the bottom of the steel bar 17 is abutted with a driving roller 11 driven by a conveying mechanism , the frame 1 is rotatably provided with a straightening drum 18 for the steel bar 17 to pass through, and the straightening drum 18 is symmetrically provided with two straightening mechanisms connected by an adjusting mechanism, and the straightening mechanism includes several rotationally arranged Straightening pinch roller 24, straightening pinch roller 24 and steel bar 17 pressure abutting settings.

[0023] The general working process of the device is as follows: the steel bar 17 that needs to be straightened is conveyed through the conveying mechanism, the steel bar 17 enters the inside of the straightening drum 18, and the straightening drum 18 drives the internal adjustment mechanism to r...

Embodiment 2

[0029] On the basis of Embodiment 1, in order to ensure that the steel bars 17 are fully straightened by the straightening mechanism, that is, the pressure straightening time of specific parts is guaranteed, the conveying mechanism in the device includes a worm 12 driven by a motor 10, and the worm The upper meshing of 12 is equipped with a worm wheel 14, the worm wheel 14 is coaxially fixed with a driving semicircular gear 13, and the driving roller 11 is coaxially fixed with a driven gear 9 matching with the driving semicircular gear 13, and the outer side of the straightening drum 18 The outer ring gear 16 is fixed on the wall sleeve, and the drive gear 15 coaxially fixed with the worm 12 is connected to the bottom of the outer ring gear 16 .

[0030] The motor 10 drives the worm 12 to rotate, and the worm 12 drives the worm wheel 14 to rotate together with the driving semicircular gear 13. While the driving semicircular gear 13 rotates, it is intermittently meshed with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com