Ultrasonic vibration meter

A technology of ultrasonic wave and vibration instrument, which is applied in the field of experimental equipment, can solve the problems of non-vibration of experimental vessels, poor oscillation effect, influence on oscillation and cell lysis effect, and achieve automatic opening and closing, avoiding excessive movement, and preventing stalling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

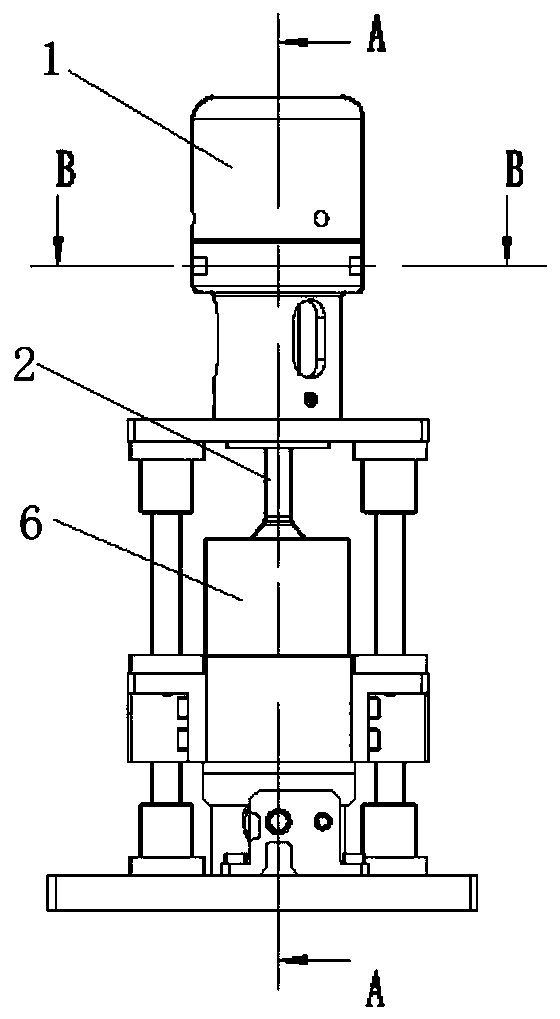

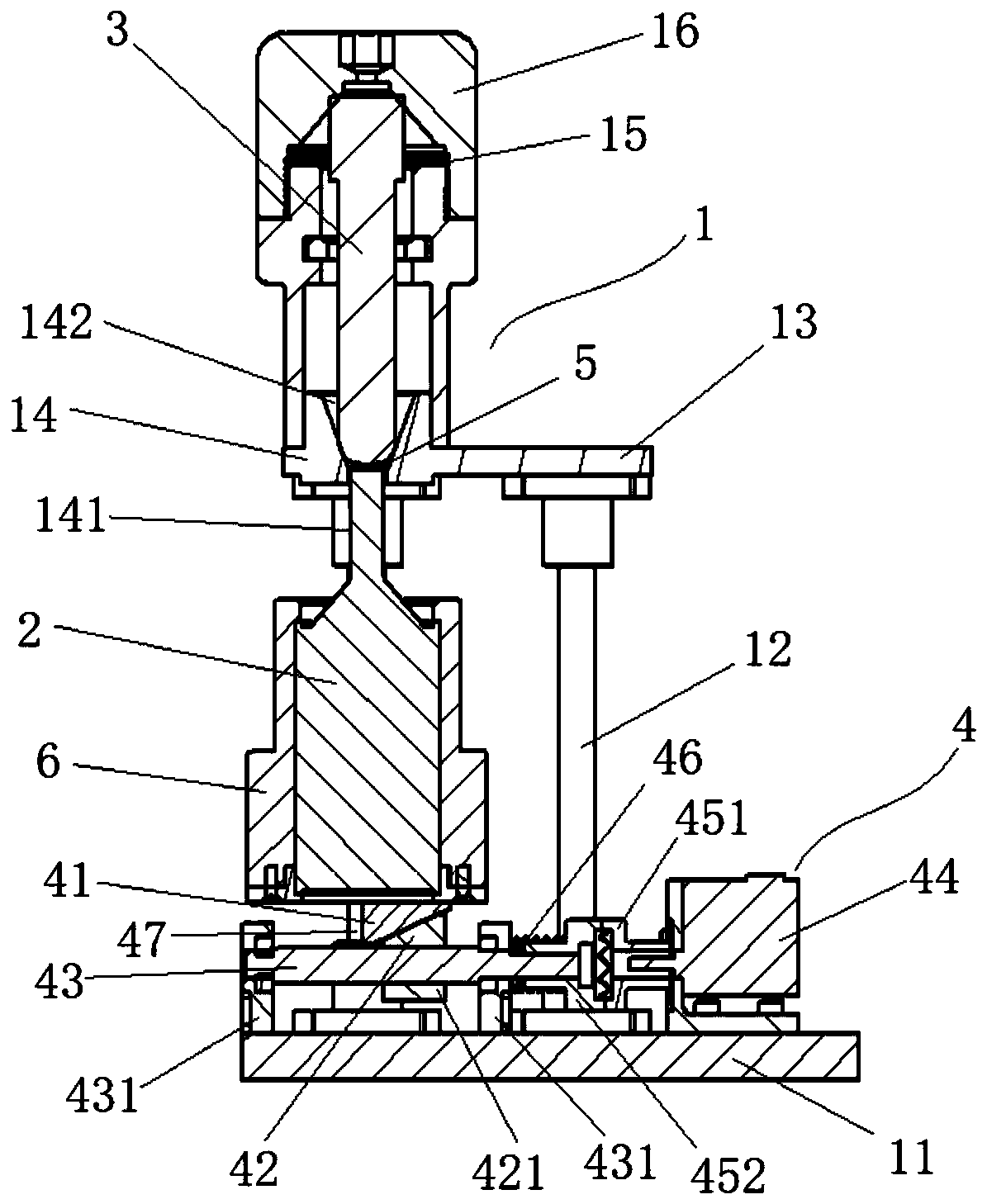

[0045] This embodiment relates to a kind of ultrasonic vibration instrument, its structure is as follows Figure 1~4 As shown, it includes a laboratory vessel fixing frame 1 and an ultrasonic generator 2 . In this embodiment, the experimental vessel 3 is a test tube. In this embodiment, the ultrasonic generator is an ultrasonic vibrator. The experimental vessel 3 is fixed in the experimental vessel holder 1, the sonotrode 2 is arranged inside the sonotrode shell 6, and the top of the sonotrode 2 abuts against the bottom end of the test vessel 3, and the bottom of the sonotrode shell 6 is arranged There is a lifting mechanism 4. In the implementation shown in this example, the lifting mechanism 4 includes an upper guide block 41, a lower guide block 42, a screw rod 43, a drive motor 44 and a limiter 47, wherein: the top of the upper guide block 41 is fixedly arranged on the ultrasonic The bottom of the generator housing 6; the upper guide block 41 and the lower guide block 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com