Battery and method for pinching tab on side negative electrode plate of battery

A side negative plate and battery technology, applied in lead-acid batteries, lead-acid battery construction, battery pack components, etc., can solve the problems of unstable side and negative plate pinching effect, affecting battery life, etc., and achieve the effect of input and output Good, life-enhancing, low-temperature performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

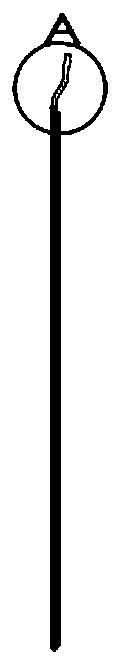

[0058] Step 1: On the frame of the side negative plate, the length of 1mm from the frame of the side negative plate is used as the bending point, and the tabs at this distance have no horizontal offset;

[0059] Step 2: Bending the tab at the bending point in step 1, the bending angle is 120°, and the length B of the bent tab in the vertical direction is 4mm;

[0060] Step 3: On the basis of step 2, bend the upper part of the tab of the side negative plate. The horizontal offset distance of the tab of this section is 0.5mm, and the tab is pinched to complete.

Embodiment 2

[0062] Step 1: On the frame of the side negative plate, the length of 3mm from the frame of the side negative plate is used as the bending point, and the tabs at this distance have no horizontal offset;

[0063] Step 2: Bending the tab at the bending point in step 1, the bending angle is 140°, and the length B of the bent tab in the vertical direction is 4.5mm;

[0064] Step 3: On the basis of step 2, bend the upper part of the tab of the side negative plate. The horizontal offset distance of the tab of this section is 1mm, and the tab is pinched to complete.

Embodiment 3

[0066] Step 1: On the frame of the side negative plate, the length of 2mm from the frame of the side negative plate is used as the bending point, and the tabs at this distance have no horizontal offset;

[0067] Step 2: Bending the tab at the bending point in step 1, the bending angle is 135°, and the length B of the bent tab in the vertical direction is 4.2 mm;

[0068] Step 3: On the basis of step 2, bend the upper part of the tab of the side negative plate. The horizontal offset distance of the tab of this section is 0.8mm, and the tab is pinched to complete.

[0069] Another embodiment of the present invention discloses a storage battery, which includes a casing and a battery electrode group disposed inside the casing. The tabs of the negative plate on the side of the battery electrode group are kneaded by the method of Embodiments 1 to 3.

[0070] Specifically, the battery electrode group in this embodiment includes positive plates, negative plates, positive tabs, negativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com