High efficiency/color quality/color stability laminated white light organic light emitting diode

A technology of light-emitting diodes and white light, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of unfavorable device low cost, large-scale industrial production, complex device structure, and long preparation cycle, and achieve Good bipolar transmission performance, high device efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0095] During the preparation process of the device, the evaporation rate of the material and the thickness of the organic and inorganic film layers are monitored and controlled by a quartz crystal frequency meter connected outside the vacuum chamber. Among them, organic materials, MoO 3 The evaporation rates of LiF, LiF, and Al are about 1Å / s, 0.3Å / s, 0.1Å / s, and 3Å / s, respectively. The overlapping part of the ITO glass and the aluminum cathode is used as the effective light-emitting layer of the device, and the effective light-emitting area is 3mm×3mm.

[0096] The performance test method of the OLED device involved in the embodiment of the present invention is as follows.

[0097] The prepared OLED device was taken out from the vacuum cavity, and the parameters such as current density, brightness, current efficiency and power efficiency of the device were measured by using a computer-integrated control BM-70A photometer and a Keithley 2400 digital source meter; using a com...

Embodiment 1

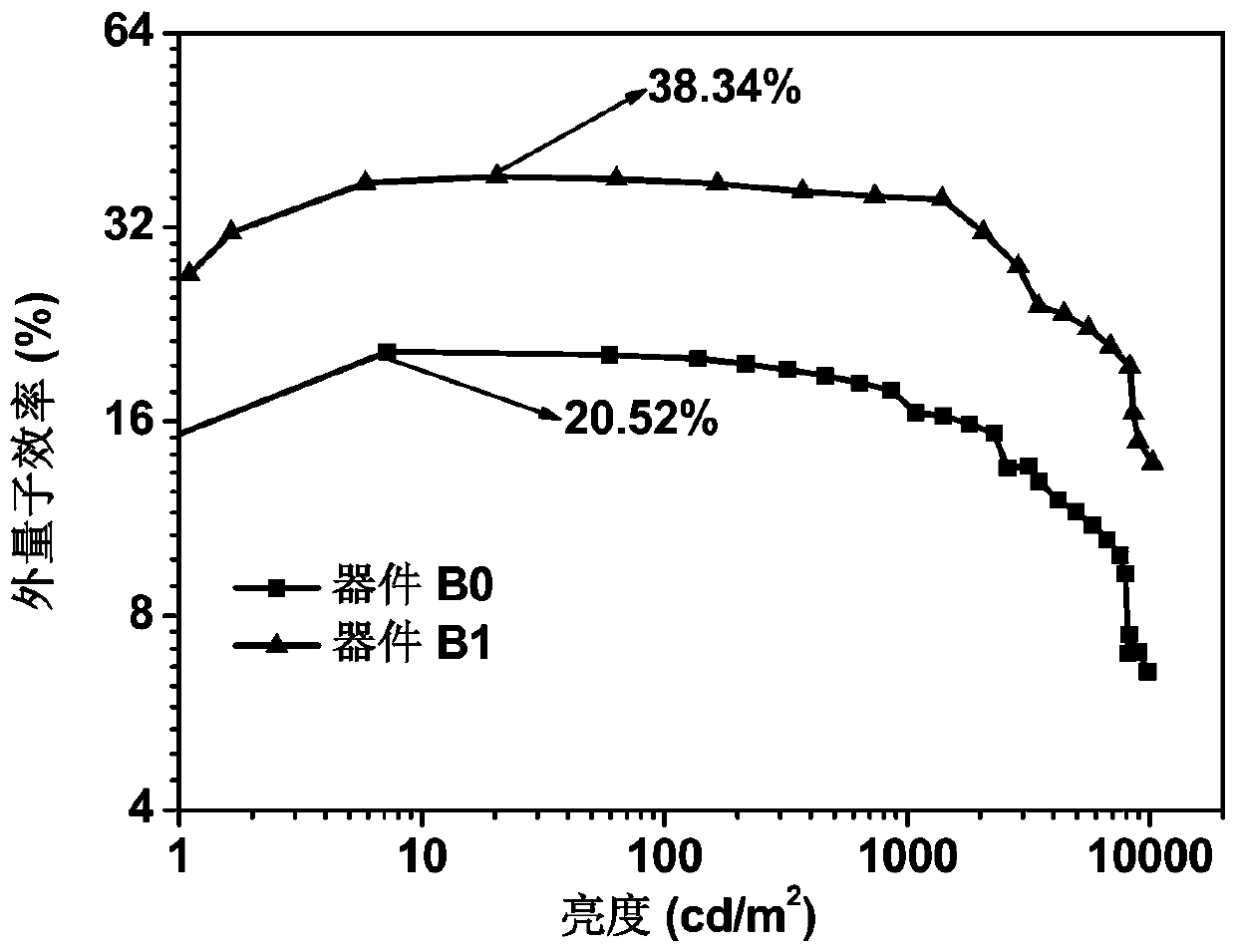

[0101] LiF / Al / HAT-CN / HAT-CN:TAPC was selected as the charge generation unit to verify the crucial role of the charge generation unit in realizing the preparation of high-performance stacked WOLEDs.

[0102] First prepare a conventional blue light device B0 as a reference, device structure: ITO (180nm) / HAT-CN (5nm) / TAPC (40nm) / TCTA:TmPyPB(1:1):15wt% FIrpic (20nm) / TmPyPB (15nm) / TmPyPB:10wt% LiF (25nm) / LiF (1nm) / Al (100nm).

[0103] Then, the above-mentioned charge generation unit is used to connect two reference blue light devices as an electroluminescence unit, and a laminated blue light device B1 based on the above-mentioned charge generation unit is prepared, the device structure: ITO (180nm) / HAT-CN (5nm) / TAPC( 40nm) / TCTA:TmPyPB(1:1):15wt% FIrpic (20nm) / TmPyPB (15nm) / TmPyPB:10wt% LiF(25nm) / LiF (1nm) / Al (3nm) / HAT-CN (10nm) / HAT-CN:TAPC (2:1, 80nm) / TAPC(40nm) / TCTA:TmPyPB(1:1):15wt% FIrpic (20nm) / TmPyPB (15nm) / TmPyPB:10wt% LiF(25nm) / LiF ( 1nm) / Al (100nm).

[0...

Embodiment 2

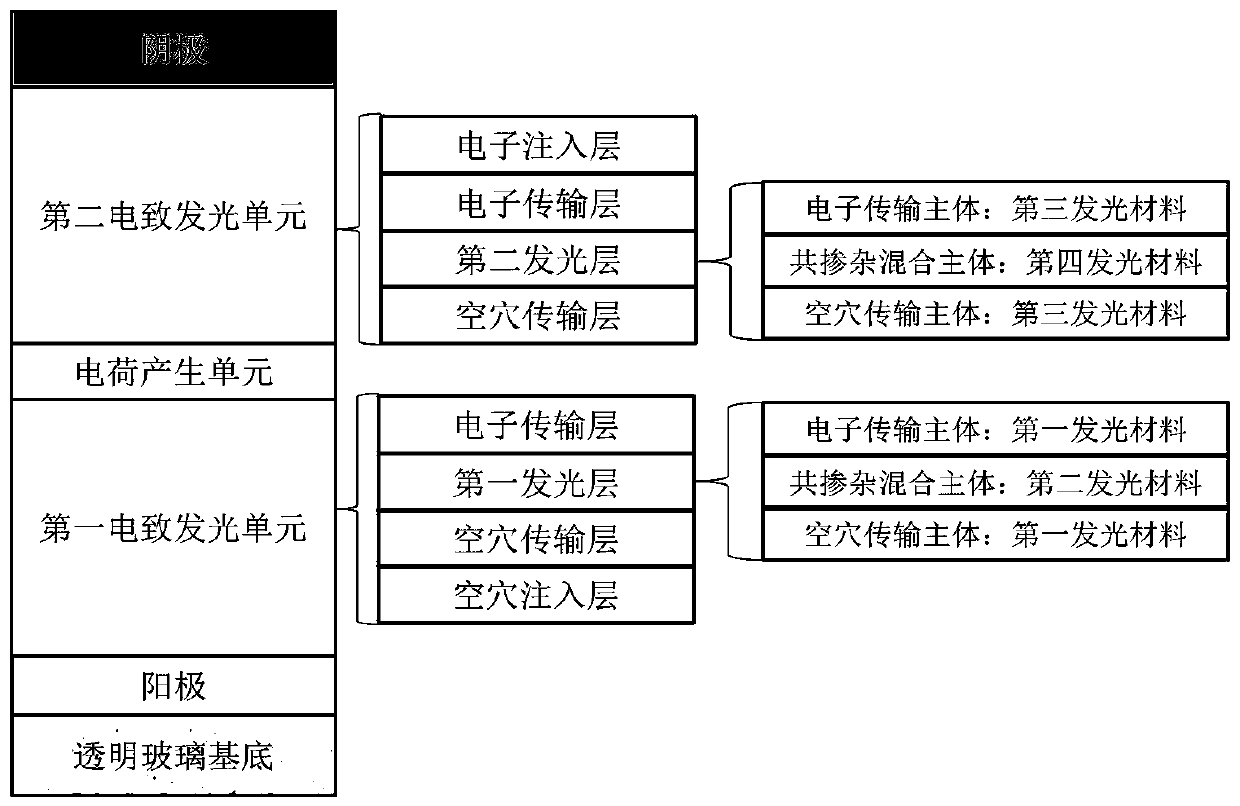

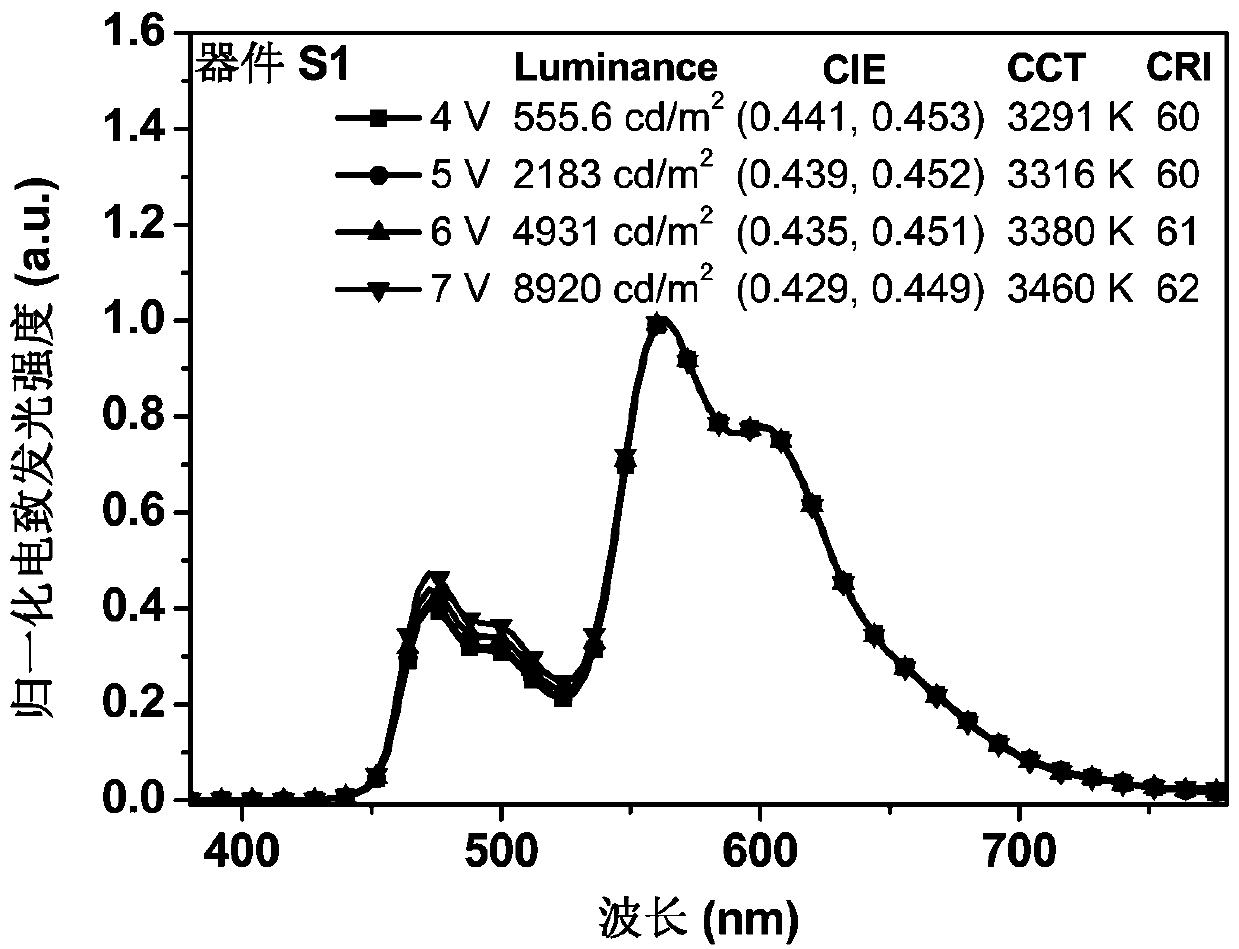

[0109] In order to verify that the device structure of the sandwich body symmetric light-emitting layer structure can achieve high device efficiency and color stability, and to develop three-color and four-color high-color quality laminated WOLEDs in subsequent examples, this example prepared a sandwich-based symmetric WOLED. The yellow / blue / yellow, red / green / red and red / yellow / red symmetrical light-emitting layers of the light-emitting layer structure constitute single light-emitting unit two-color white light devices S1, S2 and S3.

[0110] Yellow / blue / yellow symmetrical light emitting layer device S1: ITO (180nm) / HAT-CN (5nm) / TAPC (40nm) / TCTA:6wt% Ir(BT) 2 (acac) (3nm) / TCTA:TmPyPB (1:1):15wt% FIrpic (15nm) / TmPyPB:6wt% Ir(BT) 2 (acac) (3nm) / TmPyPB (15nm) / TmPyPB:10wt% LiF (25nm) / LiF (1nm) / Al (100nm).

[0111] Red / green / red symmetrical light-emitting layer device S2: ITO (180nm) / HAT-CN (5nm) / TAPC (40nm) / TCTA:6wt% Ir(piq) 2 (acac) (3nm) / TCTA:Bepp 2 (1:1):8wt% Ir(ppy) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com