Ignition generating line power supply control circuit

A busbar power supply and control circuit technology, used in weapon accessories, ammunition testing, ammunition and other directions, can solve problems such as abnormal busbar power supply, hidden dangers, and live ignition busbars, so as to improve safety and reliability, prevent malfunction, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

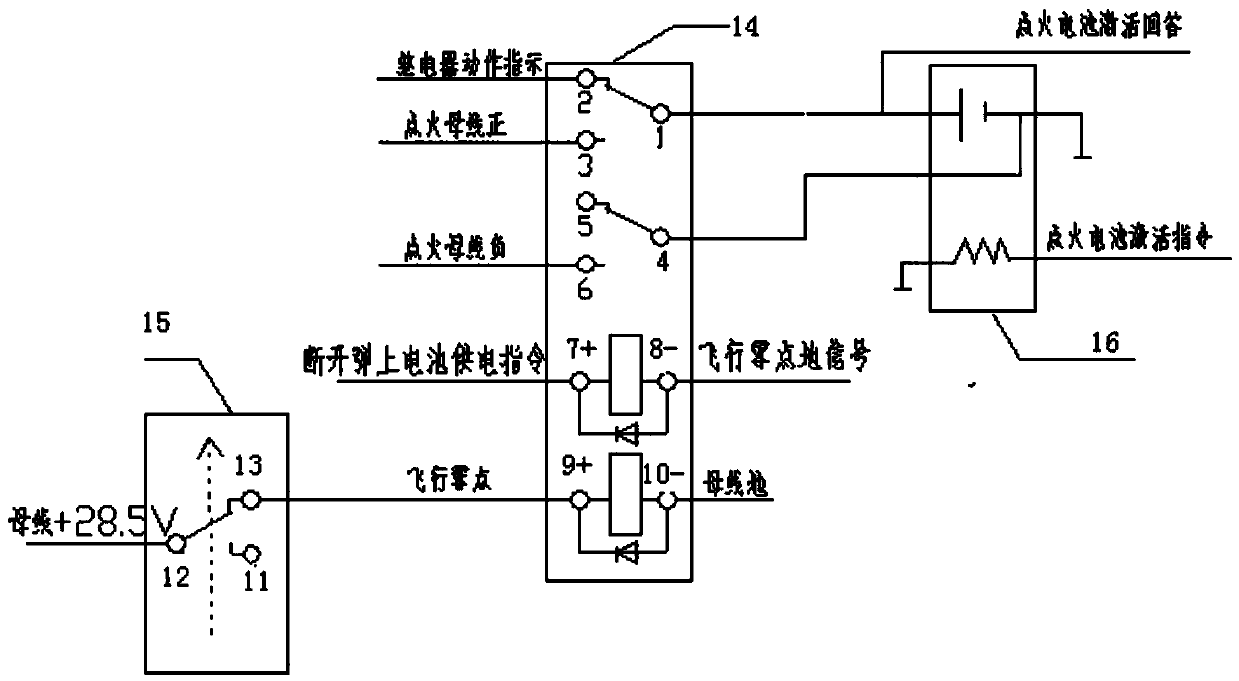

[0013] The present invention comprises an ignition battery control relay 14, a travel switch 15 and an ignition battery 16. The ignition battery control relay 14 is a magnetic latching relay, and its two sets of contacts are respectively connected with the positive and negative lines of the ignition bus to control the connection between the ignition bus and the electric fire. On-off of the battery; the front-stage excitation of the relay is connected with the control signal of the ground fire control system, and the rear-stage excitation of the relay is connected with the travel switch 15. Before the missile is launched, the control signal of the fire control system controls the ignition battery control relay 14 to disconnect the ignition bus power supply Line: after the missile is launched, the flight zero point signal sent by the travel switch 15 controls the ignition battery control relay 14 to connect the power supply line of the ignition bus.

[0014] The patent of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com