Disc pump impeller

A disc pump and impeller technology, applied in the design and manufacture of disc pump impellers, can solve problems such as excessive collision cutting, damage to guide vanes, damage to the integrity of transported materials, etc., to improve hydraulic performance, reduce cutting damage, and improve air. effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

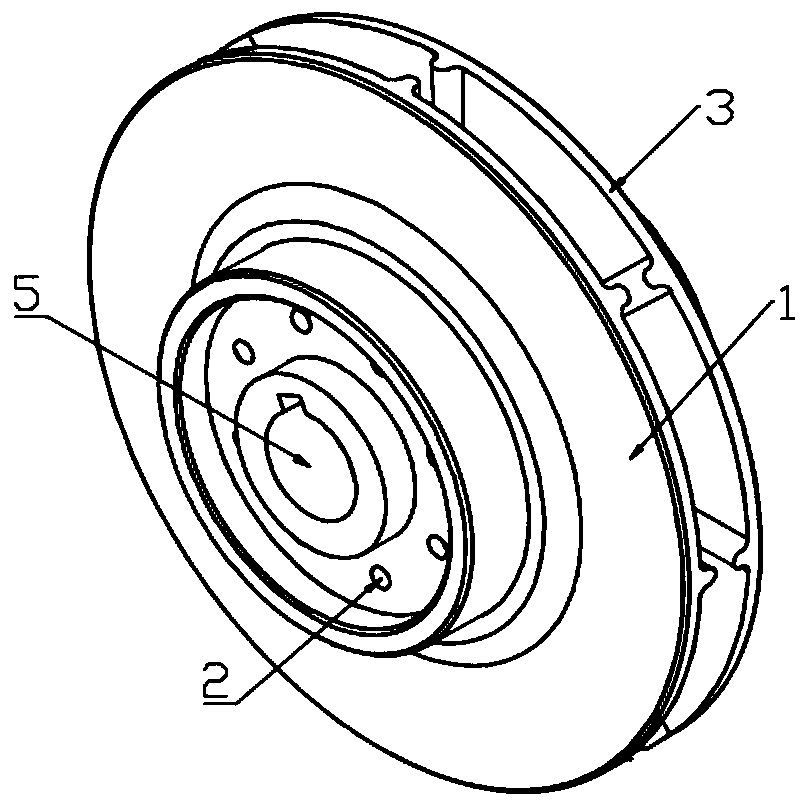

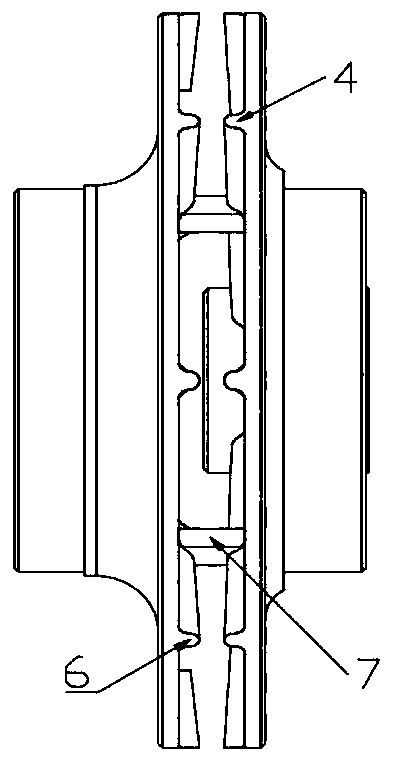

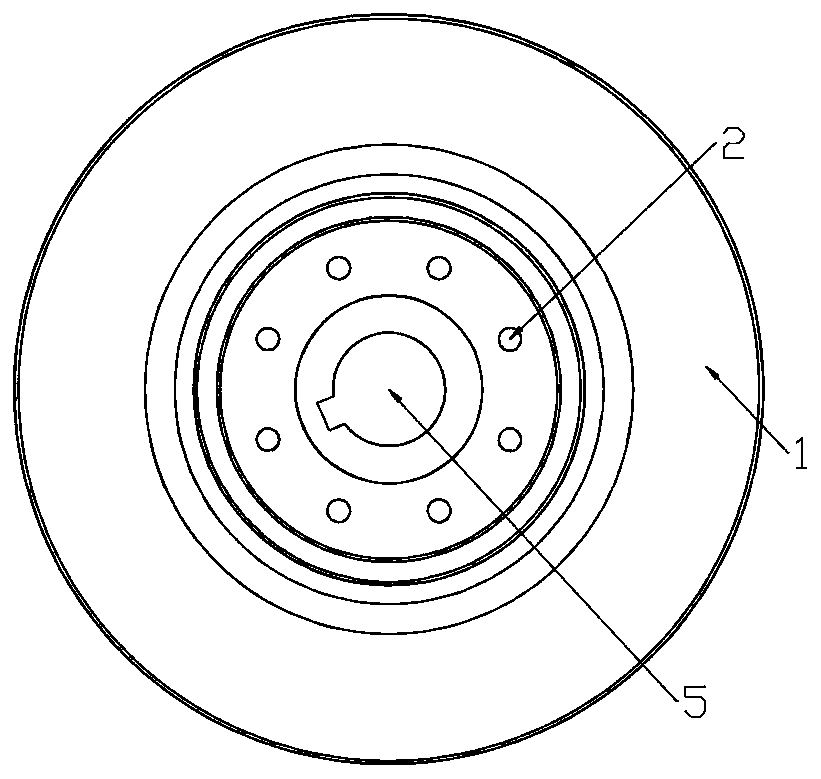

[0039] It includes the front cover 1 of the impeller and the balance hole 2 on the surface of the front cover 1 to balance the axial force. On the surface of the front cover 1, there is a hub 5 connected to the bearing of the generator and an arc-shaped front cover guide vane 4 , the front cover 1 is connected to the rear cover 3 through a cylindrical connection key 7, and there is a rear cover guide vane 6 similar to the front cover guide vane 4 on the rear cover 3

[0040] The balance hole 2 on the front cover plate 1 is used to balance the axial force generated by the impeller, reduce the wear of the bearing end face and the wear of the thrust plate, protect the bearing, the thrust plate and control the pump pressure. Wheel hub 5 is in order to cooperate with generator rotating bearing. The radius of the circle of the guide vane section of the front shroud guide vane 4 near the hub 5 is the smallest, and the radian is also the smallest. The radius and radian of the section ...

Embodiment 2

[0042] Referring to Embodiment 1, the other features remain unchanged, the short guide vane 8 of the front cover is added on the front cover 1, and the short guide vane 9 of the rear cover is added on the rear cover 3

Embodiment 3

[0044] It includes the front cover plate 1 of the impeller and the balance hole 2 on the surface of the front cover plate 1 for balancing the axial force. Nail-shaped front cover guide vanes 4, the front cover guide vanes 4 are evenly distributed in the radial direction, the front cover 1 is connected to the rear cover 3 through a cylindrical connection key 7, and the front cover guide vanes are connected to the front cover guide vanes on the rear cover 3 4 similar spike rear cover guide vanes 6

[0045] The balance hole 2 on the front cover plate 1 is used to balance the axial force generated by the impeller. It reduces the wear of the bearing end face and the wear of the thrust disc, which plays a role in protecting the bearing, the thrust disc and controlling the pump pressure. Wheel hub 5 is in order to cooperate with generator rotating bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com