Electric centrifugal pump

A centrifugal pump and electric technology, applied in the field of centrifugal pumps, can solve the problems of coil insulation burnout, hidden reliability problems, flow loss, etc., and achieve the effect of solving heat load problems, improving work reliability, and reducing flow loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

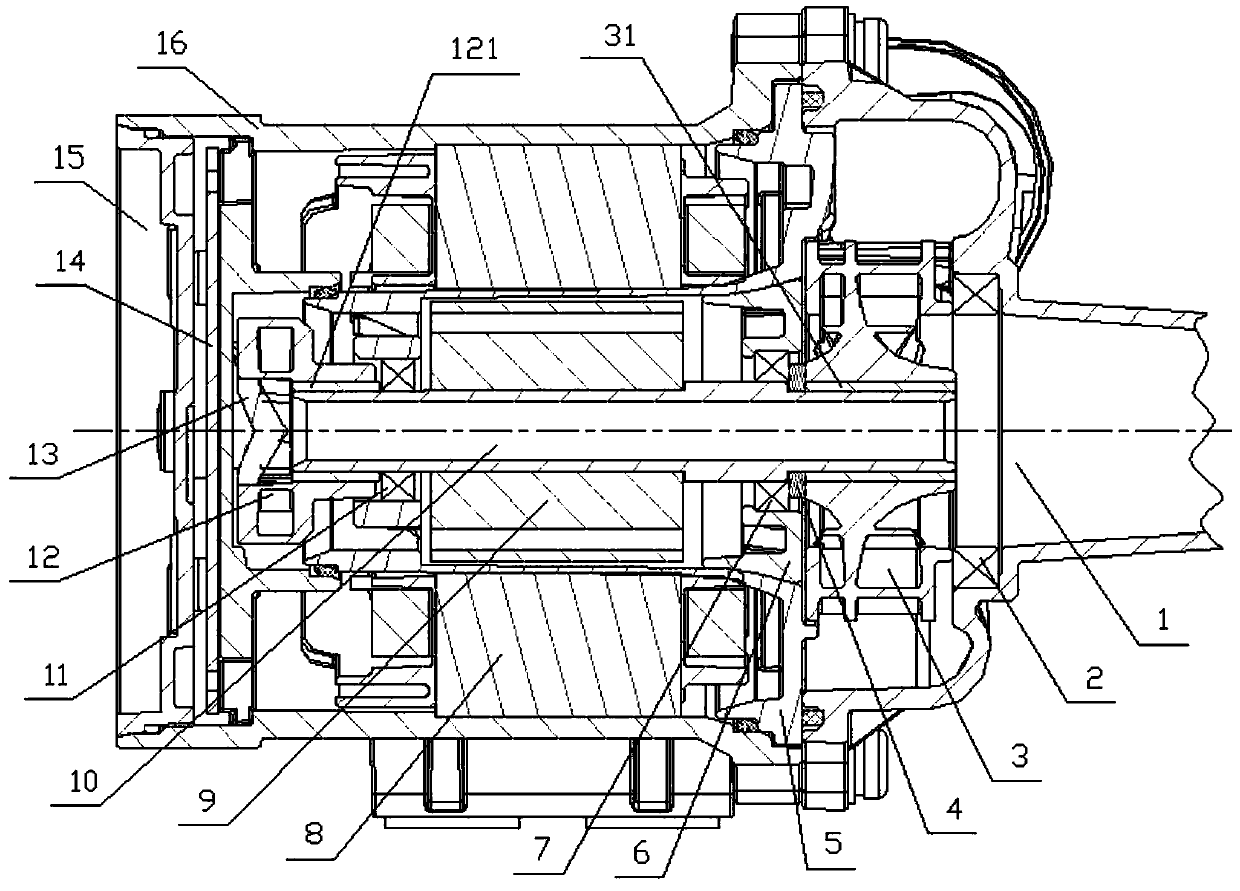

[0019] Embodiment: an electric centrifugal pump.

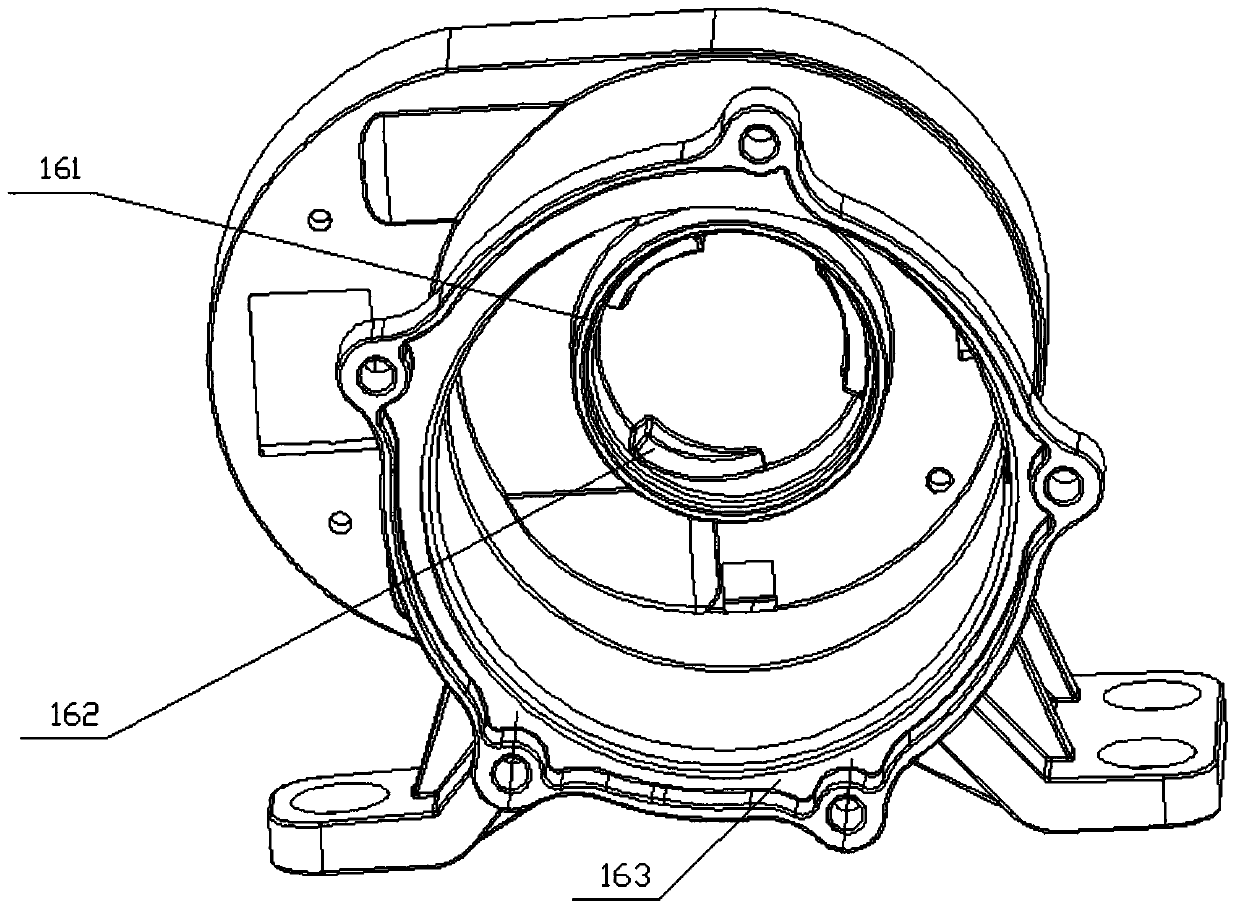

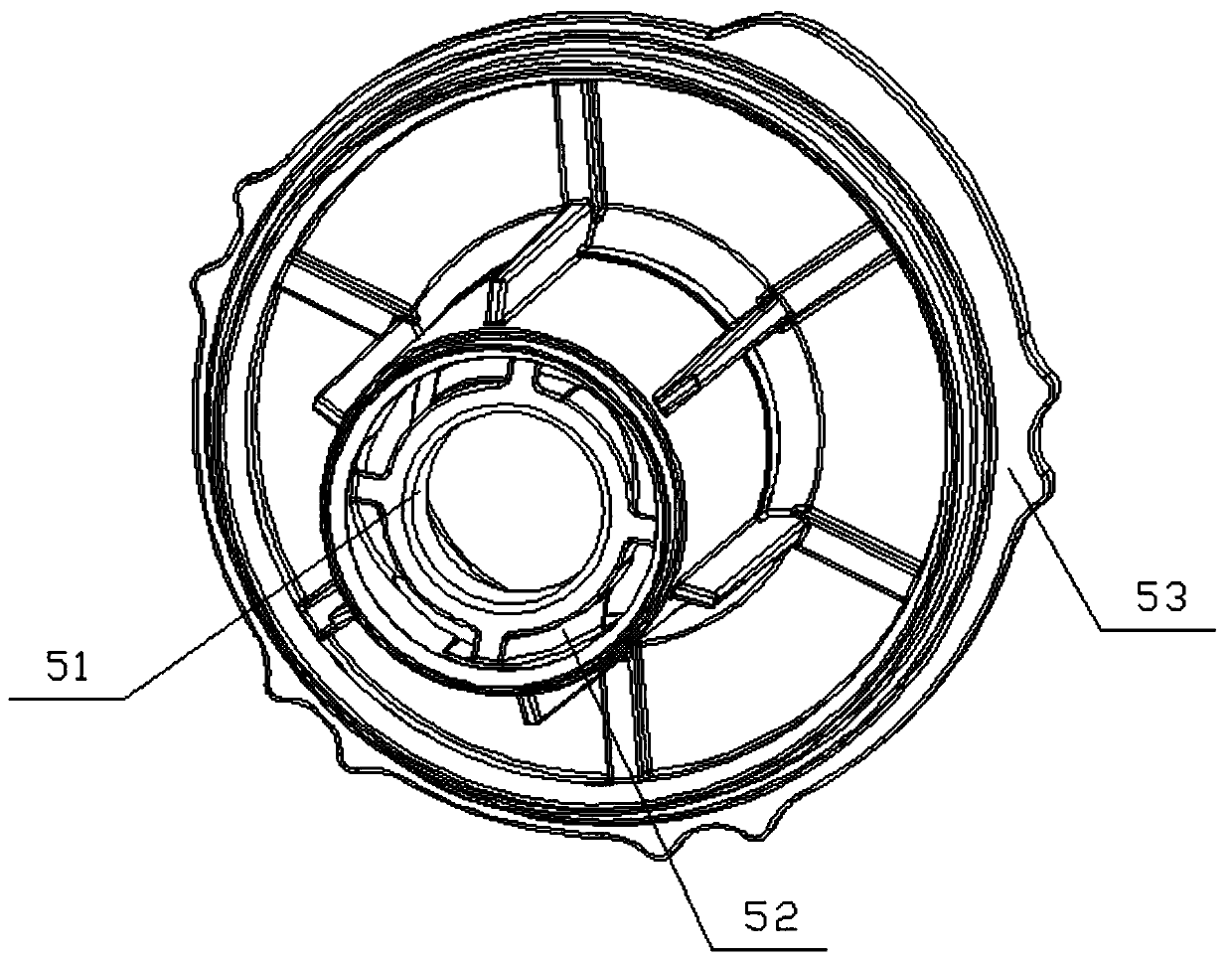

[0020] refer to Figure 1 to Figure 4 As shown, an electric centrifugal pump includes a water pump housing 1, a water-sealing bearing 2, a water pump impeller 3, an elastic washer 4, a motor inner cover 5, a bearing seat 6, a rotor front bearing 7, a motor stator 8, a motor rotor 9, Motor rotor shaft 10, motor rotor rear bearing 11, pilot impeller 12, pilot impeller cover 13, water pump drive control board 14, controller cover 15 and motor casing 16, wherein the central part of the inner cavity bottom of the motor casing 16 is provided with a circle of protrusions The tube-shaped strap 161 is provided with a strap 162 with a spiral slope in the inner cavity of the tube-shaped strap 161, and a stopper 163 is provided at the opening of the inner cavity of the motor casing 16, and the motor stator 8 is installed on the motor casing 16 In the inner cavity hole of the motor, the motor inner cover 5 is integrally formed by the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com