An automatic mine grooving equipment based on dual hydraulic power system

A power system and hydraulic control system technology, applied in mining equipment, tunnels, earthwork drilling and mining, etc., can solve time-consuming and labor-intensive problems, and achieve the effects of improving the quality of grooves, stable power output, and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further illustrate the technical solution of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

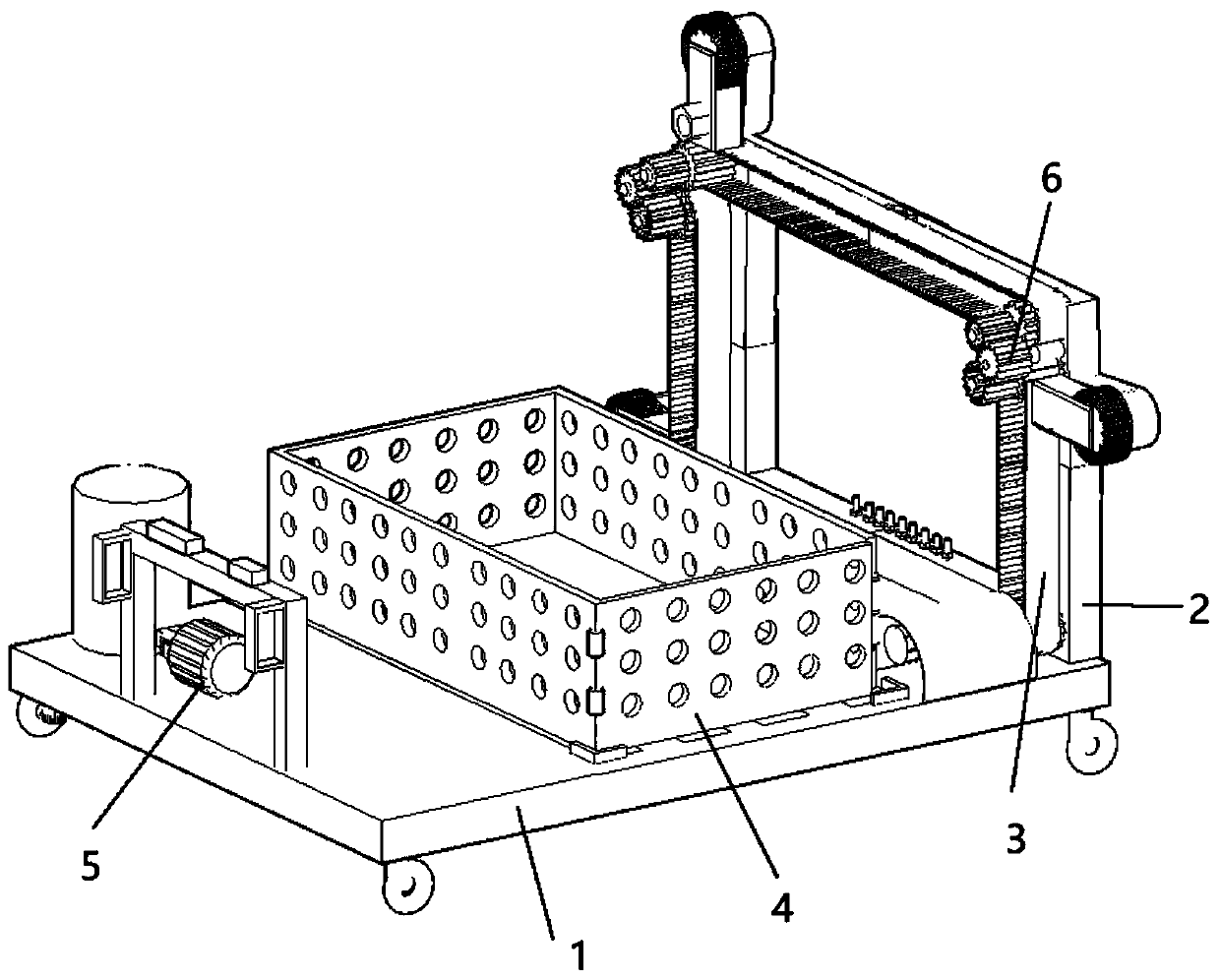

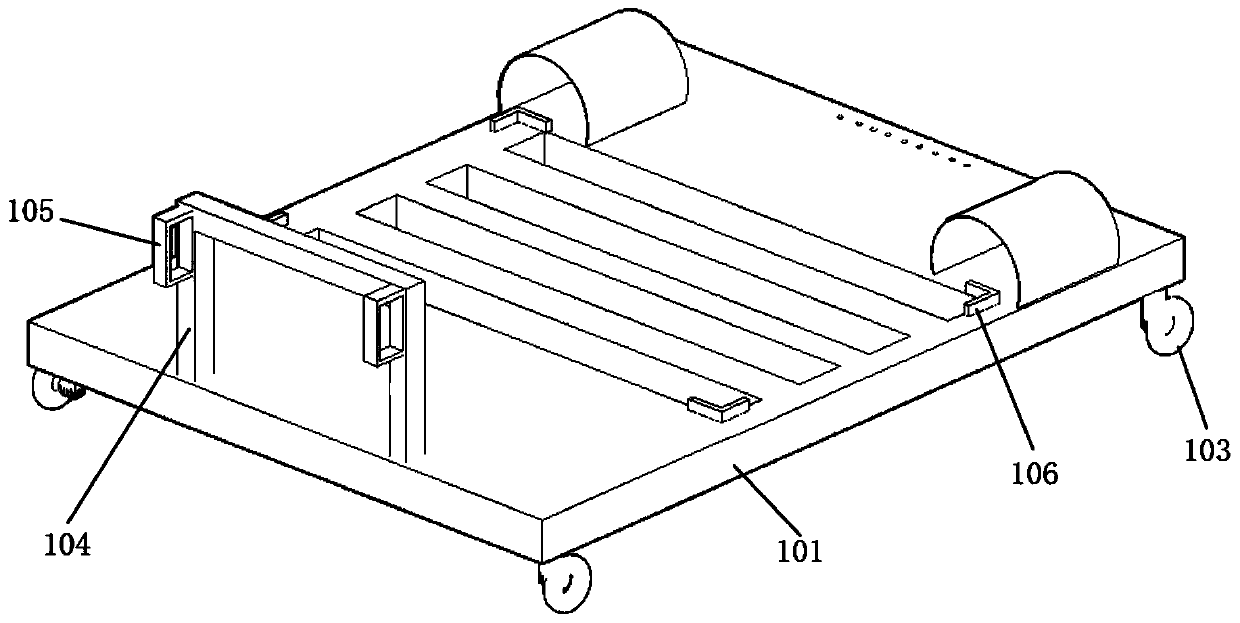

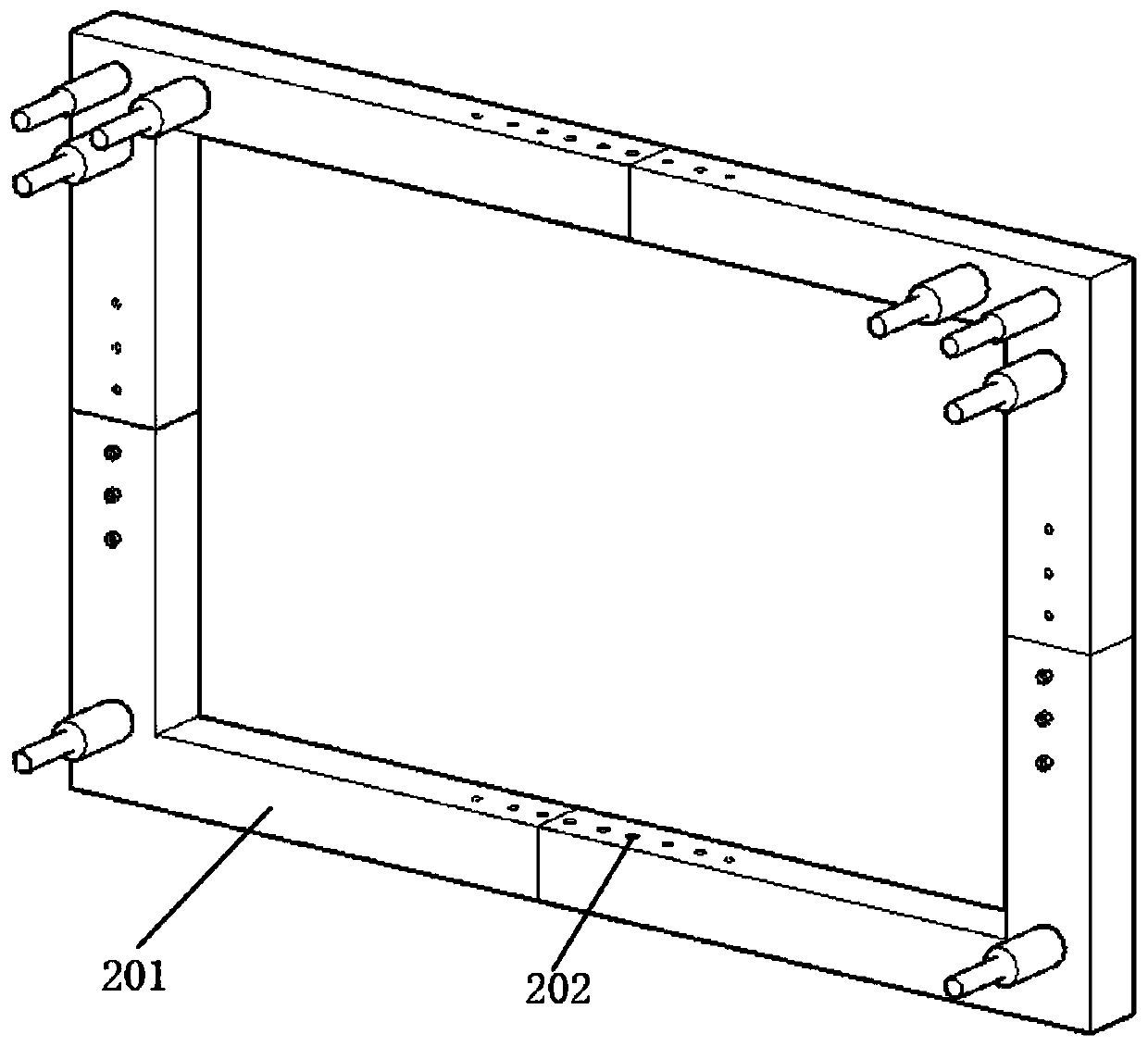

[0033] Such as figure 1 , figure 2 Shown is an automatic mine notching equipment based on a dual hydraulic power system, including a transport vehicle 1, a bracket 2, a notching device 3, a hydraulic control system 5 and a transmission gear 6, and the transport vehicle 1 includes a trolley body 101 and is arranged on Several rollers 103 on the lower surface of the trolley main body 101; the rollers 103 are universal wheels with brakes. The support 2 is arranged on the transport vehicle 1, and a set of notching device 3 is respectively arranged on the upper side and the left and right sides of the support 2, and the hydraulic control system 5 controls the work of the notching device 3 so as to make the inner wall of the mine hole Grooving, the variable speed gear 6 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com