Method and application of growing ultra-thin high-quality oxide films on two-dimensional layered materials

An oxide film, two-dimensional layered technology, applied in metal material coating process, coating, gaseous chemical plating, etc. Effects of alleviation of short channel effects, reduced capacitance effects, excellent uniformity and withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

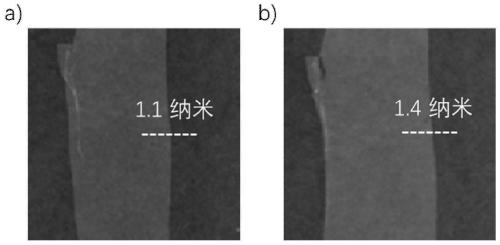

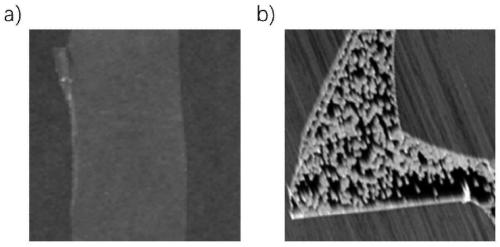

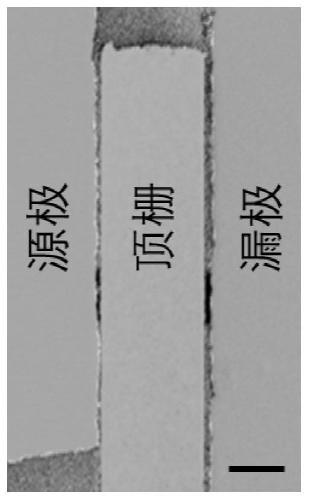

[0032]1) The graphene two-dimensional layered material is prepared by mechanical exfoliation, and the graphene two-dimensional layered material is transferred to a silicon wafer, and upper source and drain electrodes are prepared on both sides of the graphene; as figure 1 (a), Thin graphene transferred onto a silicon wafer as a substrate with a thickness of 1.1 nm.

[0033] 2) Put 3,4,9,10-perylenetetraic acid dianhydride powder into a quartz boat as a growth source, and put the quartz boat into the center of the tube furnace; place the silicon wafer transferred with graphene on another on the quartz boat, and put the quartz boat into the quartz tube, 2 cm away from the quartz boat containing the 3,4,9,10-perylenetetraic acid dianhydride powder; after placing, install the quartz tube into the tube type corresponding position of the furnace, and vacuumize;

[0034] 3) Start the tube furnace, raise the temperature of the furnace body to 240°C in 10 minutes, then raise the tempe...

Embodiment 2

[0046] 1) The graphene two-dimensional layered material is prepared by mechanical exfoliation, and the graphene two-dimensional layered material is transferred to a silicon wafer;

[0047] 2) Put 3,4,9,10-perylenetetraic acid dianhydride powder into a quartz boat as a growth source, and put the quartz boat into the center of the tube furnace; place the silicon wafer transferred with graphene on another on the quartz boat, and put the quartz boat into the quartz tube, 2 cm away from the quartz boat containing the 3,4,9,10-perylenetetraic acid dianhydride powder; after placing, install the quartz tube into the tube type corresponding position of the furnace, and vacuumize;

[0048] 3) Start the tube furnace, raise the temperature of the furnace body to 240°C in 10 minutes, then raise the temperature to 260°C in 5 minutes, and maintain it at 260°C for 0.8 hours, the growth source of 3,4,9,10-perylenetetraacid dianhydride powder evaporates , and deposited on the graphene; after t...

Embodiment 3

[0053] 1) The graphene two-dimensional layered material is prepared by mechanical exfoliation, and the graphene two-dimensional layered material is transferred to a silicon wafer;

[0054] 2) Put 3,4,9,10-perylenetetraic acid dianhydride powder into a quartz boat as a growth source, and put the quartz boat into the center of the tube furnace; place the silicon wafer transferred with graphene on another on the quartz boat, and put the quartz boat into the quartz tube, 2 cm away from the quartz boat containing the 3,4,9,10-perylenetetraic acid dianhydride powder; after placing, install the quartz tube into the tube type corresponding position of the furnace, and vacuumize;

[0055] 3) Start the tube furnace, raise the temperature of the furnace body to 240°C in 10 minutes, then raise the temperature to 260°C in 5 minutes, and maintain it at 260°C for 0.2 hours, the growth source of 3,4,9,10-perylenetetraacid dianhydride powder evaporates , and deposited on the graphene; after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com