Gantry crane unit based on combined type rail

A combined, gantry technology, applied in the field of gantry cranes, can solve the problems of different positions of different objects and rosin, and the inability to lift different objects at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

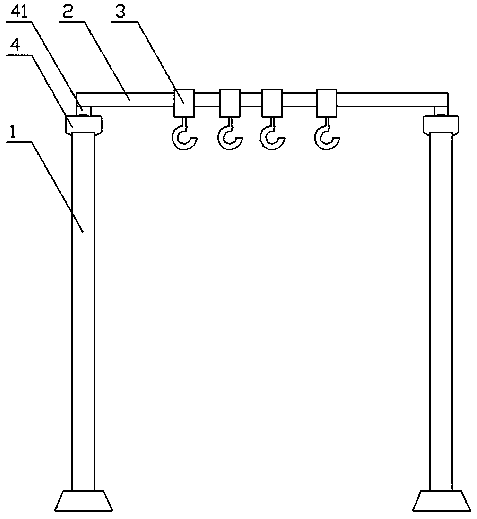

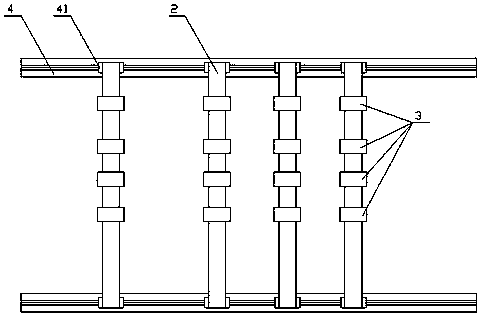

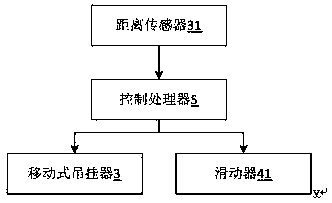

[0032] refer to Figure 1-3 , figure 1 A schematic diagram of a gantry crane unit based on a combined track provided by the present invention; figure 2 A top view schematic diagram of a track beam frame of a gantry crane unit based on a combined track provided by the present invention; image 3 A system block diagram of a gantry crane unit based on a combined track provided by the present invention.

[0033] Specifically, a gantry crane unit based on a combined track includes: a gantry support frame 1 , a gantry crane beam frame 2 , a mobile hanger 3 , and is characterized in that it also includes a track beam frame 4 and a control processor 5 .

[0034] The gantry support frame 1 includes a first support frame, a second support frame, a third support frame, and a fourth support frame, and the four are respectively arranged at four corners of a cubic space. The track beams 4 along the upper edge of the cubic space are respectively fixedly connected to the upper ends of two...

Embodiment 2

[0045] refer to Figure 4-5 , Figure 4 The second schematic diagram of the gantry crane beam frame of the gantry crane unit based on the combined track provided by the present invention; Figure 5 Appropriate figure for the track girder frame of the second combined track-based gantry crane set provided by the present invention.

[0046] This embodiment is basically the same as the first embodiment above, except that the mobile hangers of the same group have different heights. The width of the lower mobile hanger in the same group of mobile hangers is smaller than the width of another mobile hanger in the same group.

[0047] The mobile hangers 3 in the same group have different heights and widths, and the height and width of one mobile hanger 3 in the same group are higher and larger than the other mobile hanger 3 .

[0048] The higher one of the mobile hangers in the same group is provided with a through hole, and the through hole is used for another mobile hanger in the ...

Embodiment 3

[0053] refer to Figure 6-7 , Image 6 A top view schematic diagram of the track beam frame of the third combined track-based gantry crane unit provided by the present invention; Figure 7 A top view schematic diagram of the combined gantry crane unit of the third combined track-based gantry crane unit provided by the present invention.

[0054] This embodiment is basically the same as the first embodiment above, except that, preferably, the track beam frame 4 includes several sliding tracks 42 , and the sliders 41 are respectively located on different sliding tracks 42 . The same group of sliders 41 are mirror-symmetrical at the position of the sliding track 42 .

[0055] The track beam frame 4 is provided with a plurality of sliding tracks 42, and the sliding tracks 42 are parallel to each other. As one of the implementation manners, the distances between the sliding tracks 42 are consistent, several sliders 41 correspond to corresponding sliding tracks 42 , and one slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com