Garden shears with improved structure

A technology for improving structure and gardening shears, applied in the field of agricultural gardening, can solve the problems of low work efficiency, inconvenient operation, inability to cut, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

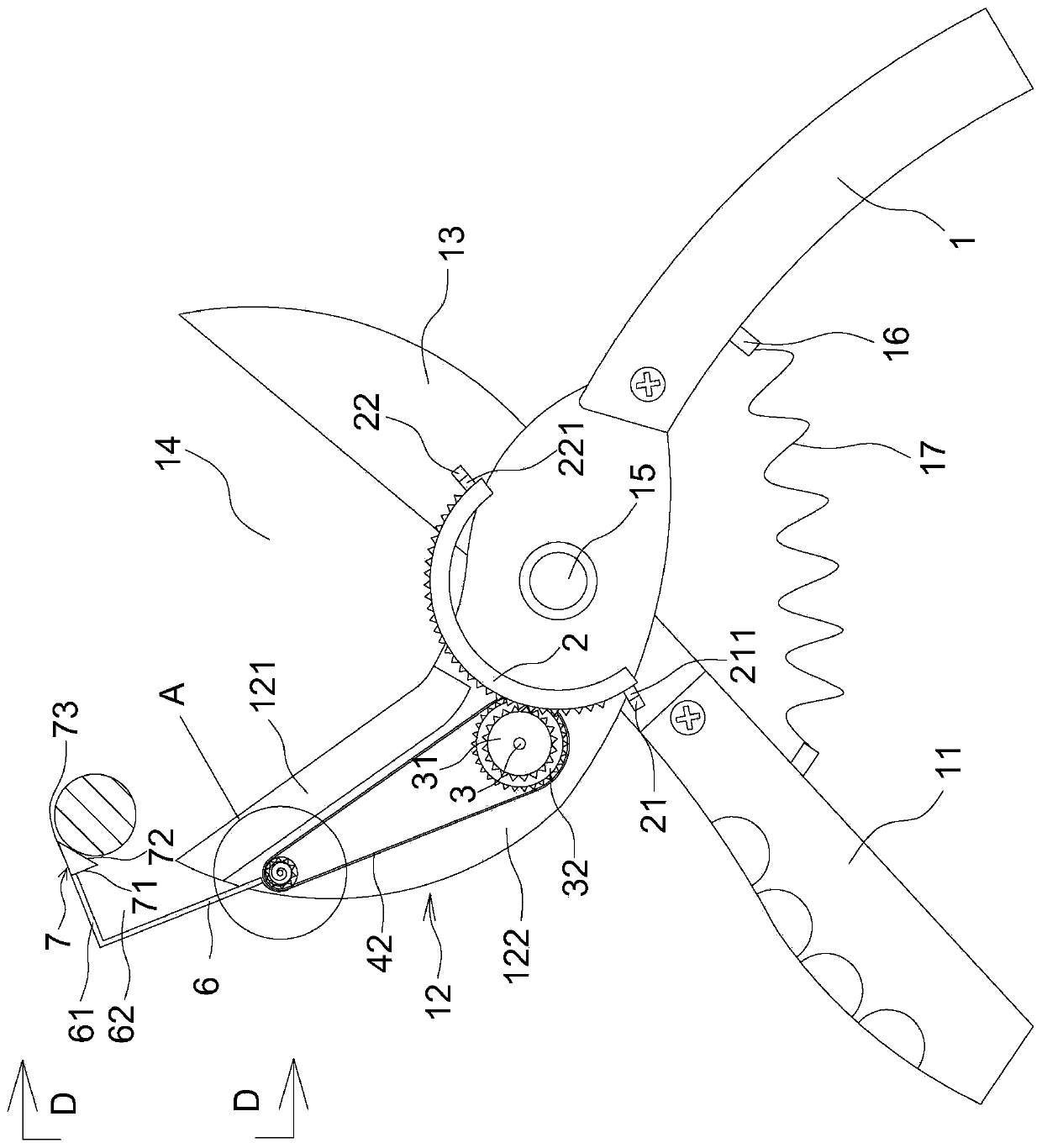

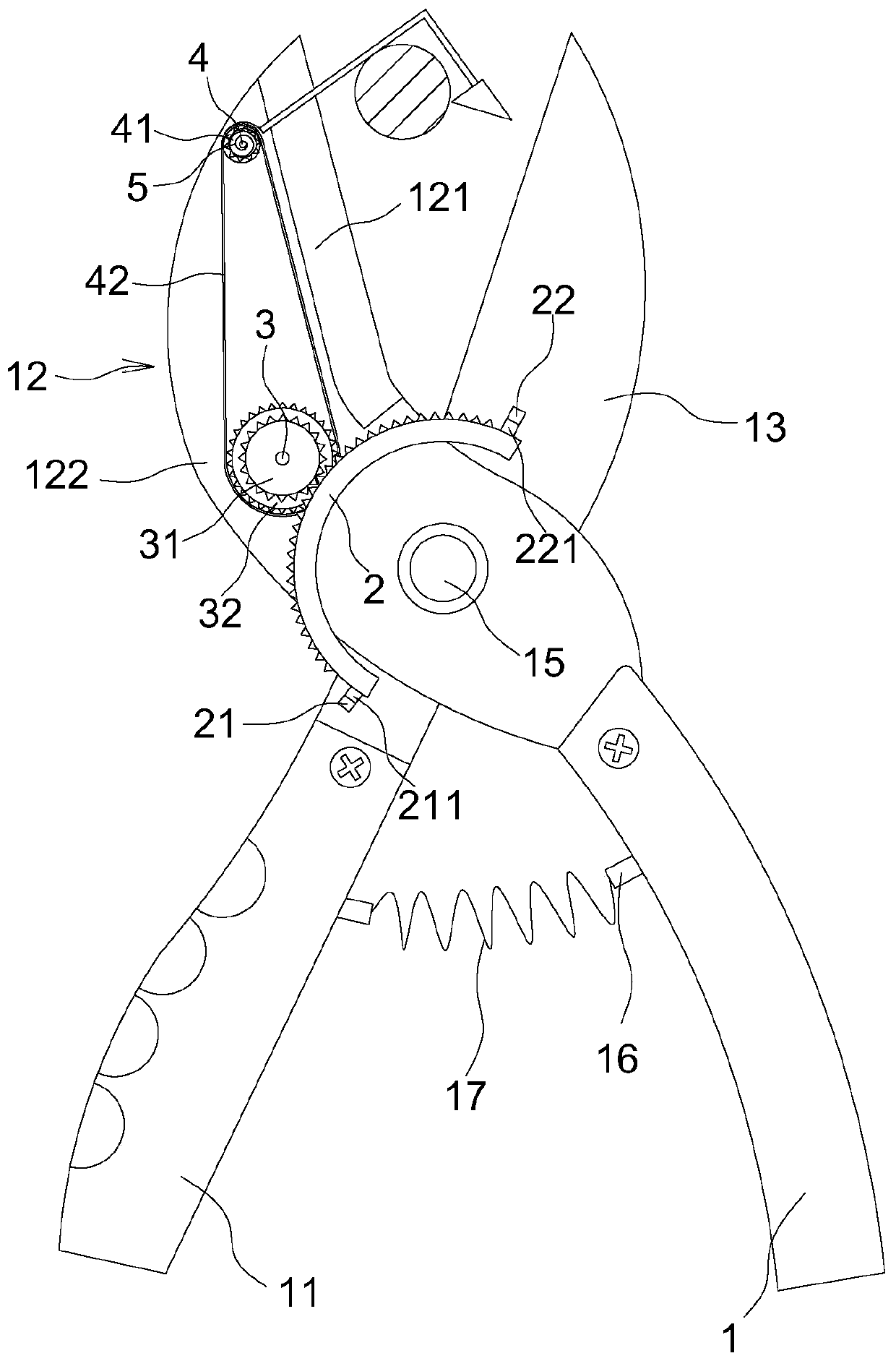

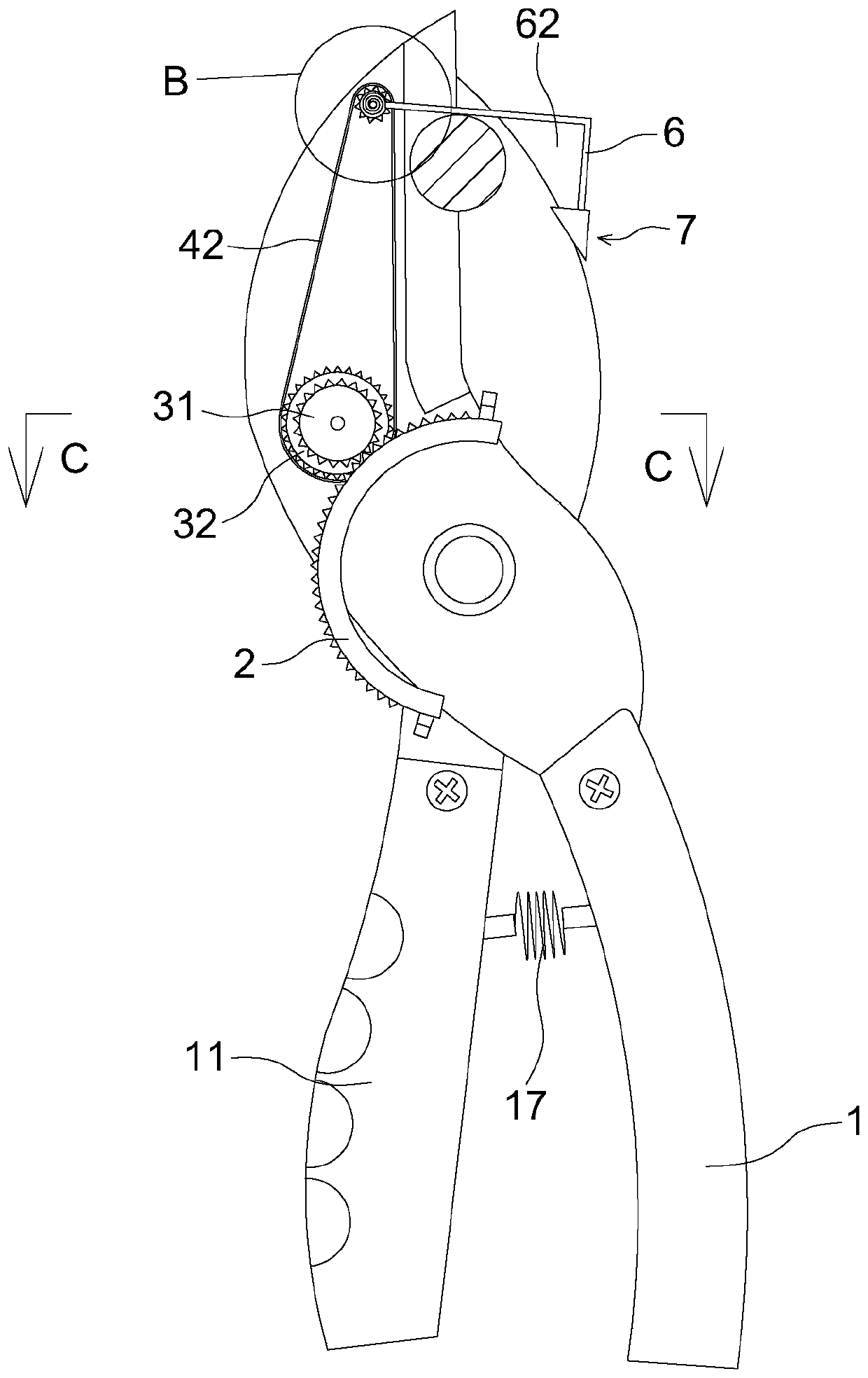

[0032] refer to Figure 1 to Figure 7 , a gardening shears with an improved structure, comprising a first blade 12 and a second blade 13 that are intersected and hinged by a hinge shaft 15, the first blade 12 is located above the second blade 13, and the lower end of the first blade 12 is fixed Connected with the first handle 1, the lower end of the second blade 13 is fixedly connected with the second handle 11 opposite to the first handle 1, and also includes:

[0033] The first rotating shaft 3, the first rotating shaft 3 is rotatably arranged on the outer side of the first blade 12 and is located near the hinge shaft 15, between the first rotating shaft 3 and the hinge shaft 15 there is a And the driving mechanism that drives the first rotating shaft 3 to rotate when the second blade 13 rotates around the hinge shaft 15;

[0034] The second rotating shaft 4, the second rotating shaft 4 is rotatably arranged on the outer surface of the first blade 12 and is located between ...

Embodiment 2

[0059] This embodiment is basically the same as the solution of Embodiment 1, the difference is:

[0060] refer to Figure 8 , the return spring 17 and the two spring connecting blocks 16 are replaced by a hydraulic rod 18, the end of the piston cylinder of the hydraulic rod 18 is hinged on the first handle 1, and the end of the piston rod is hinged on the second handle 11 Above, the first grip 1 is provided with a controller 8 and a battery 9 , and the controller 8 is electrically connected to the hydraulic rod 18 through the battery 9 .

[0061] When working, start the hydraulic rod 18, the hydraulic rod 18 will drive the first handle 1 and the second handle 11 to move, thereby driving the first blade 12 and the second blade 13 to move, and then realize the first rod 6 and the second rod 61 The sheared material is moved into the shear gap 14 . This structure facilitates the operation of the first handle 1 and the second handle 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com