Adjustable special-shaped curved surface aluminum plate mounting structure

A special-shaped curved surface and installation structure technology, which is applied in building construction, covering/lining, construction, etc., can solve the problems of difficulty in ensuring the accuracy of the installation position of the veneer, inconvenient fine-tuning of the position of each veneer, and difficulty in ensuring the final quality. Inexpensive, fast, and distance-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

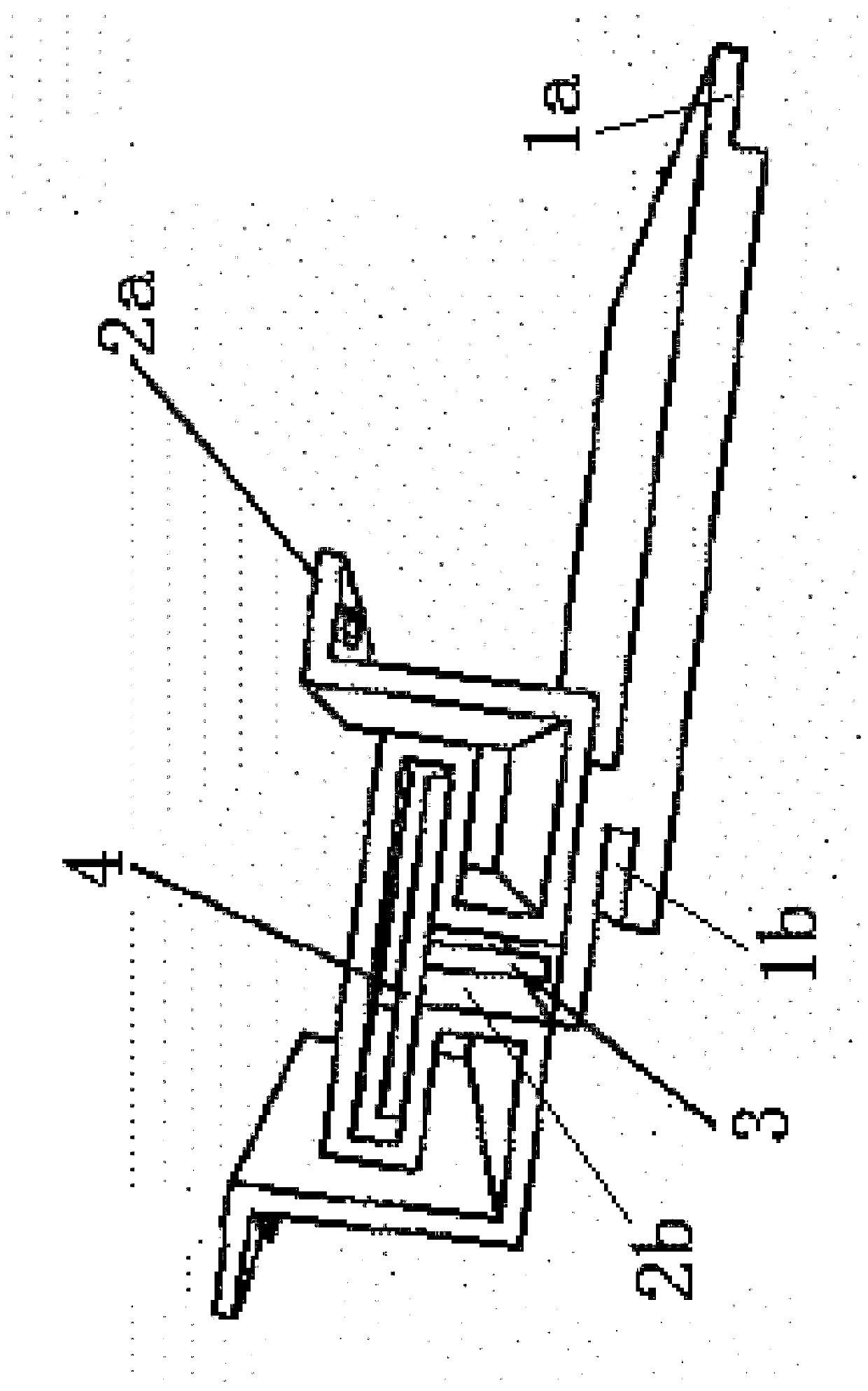

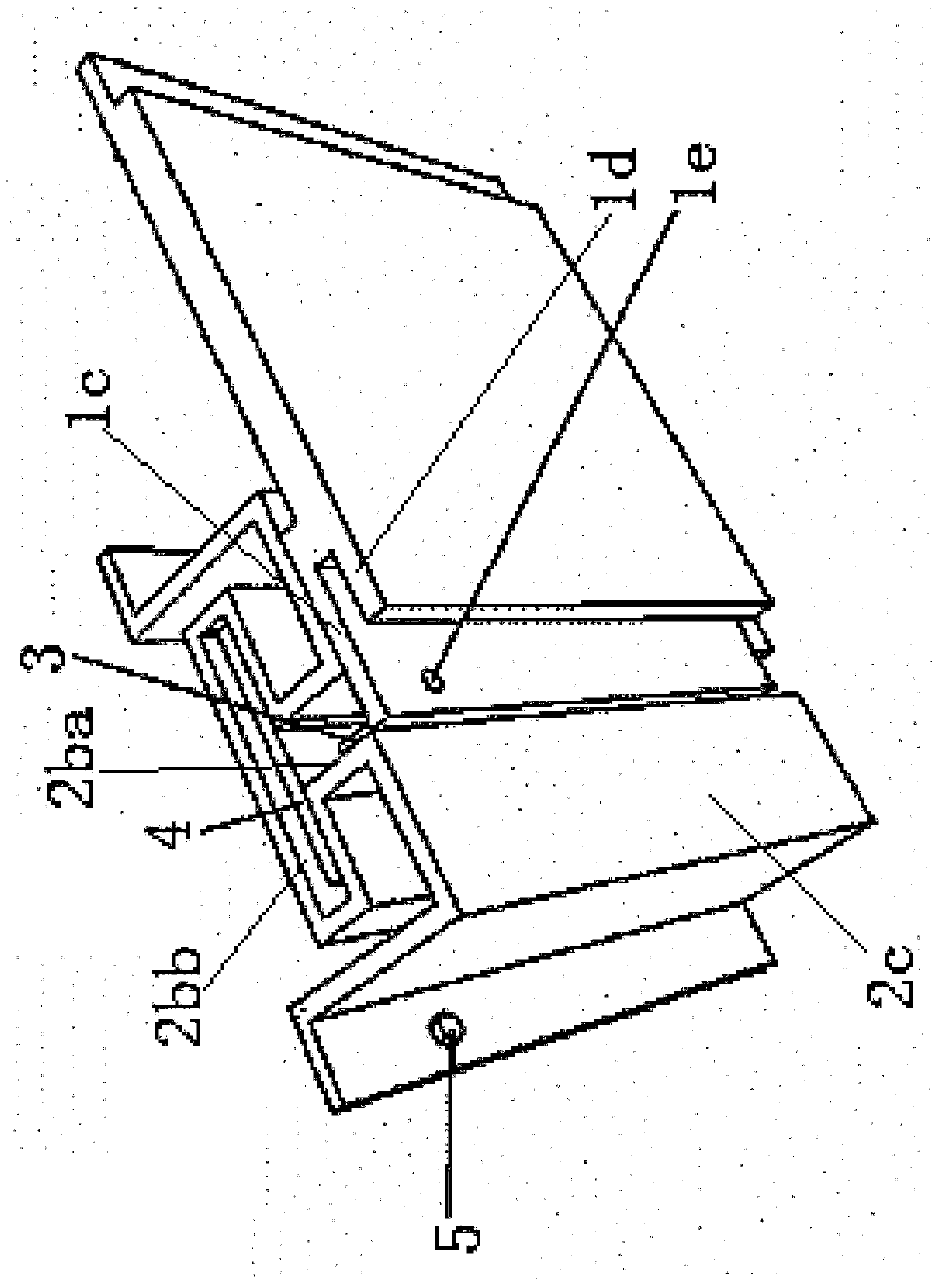

[0031] In order to achieve the purpose of the present invention, an adjustable special-shaped curved surface aluminum plate installation structure includes: the veneer 1 is provided with a first stop edge 1a and an insertion groove 1b on a pair of opposite sides of the veneer 1, and the veneer 1 The first seam edge 1a is spliced with the insertion groove 1b of the adjacent decorative panel 1, and the same side of the decorative panel 1 is provided with a second seam edge 1c and a third seam edge 1d extending in parallel, the second seam edge 1c, The gap between the third notch sides 1d constitutes the insertion groove 1b; the profile member 2 is provided with a T-shaped groove 2b composed of vertically intersecting vertical grooves 2ba and transverse grooves 2bb, and one end of the vertical groove 2ba is a T-shaped groove 2b, the two sides of the profile m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com