Wastewater treatment system

A wastewater treatment system and wastewater technology, applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage treatment equipment, etc., can solve high operating costs, low rising flow rate, reverse osmosis system fouling and scaling and other issues, to achieve the effect of realizing resource utilization, reducing operating costs, and stabilizing effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

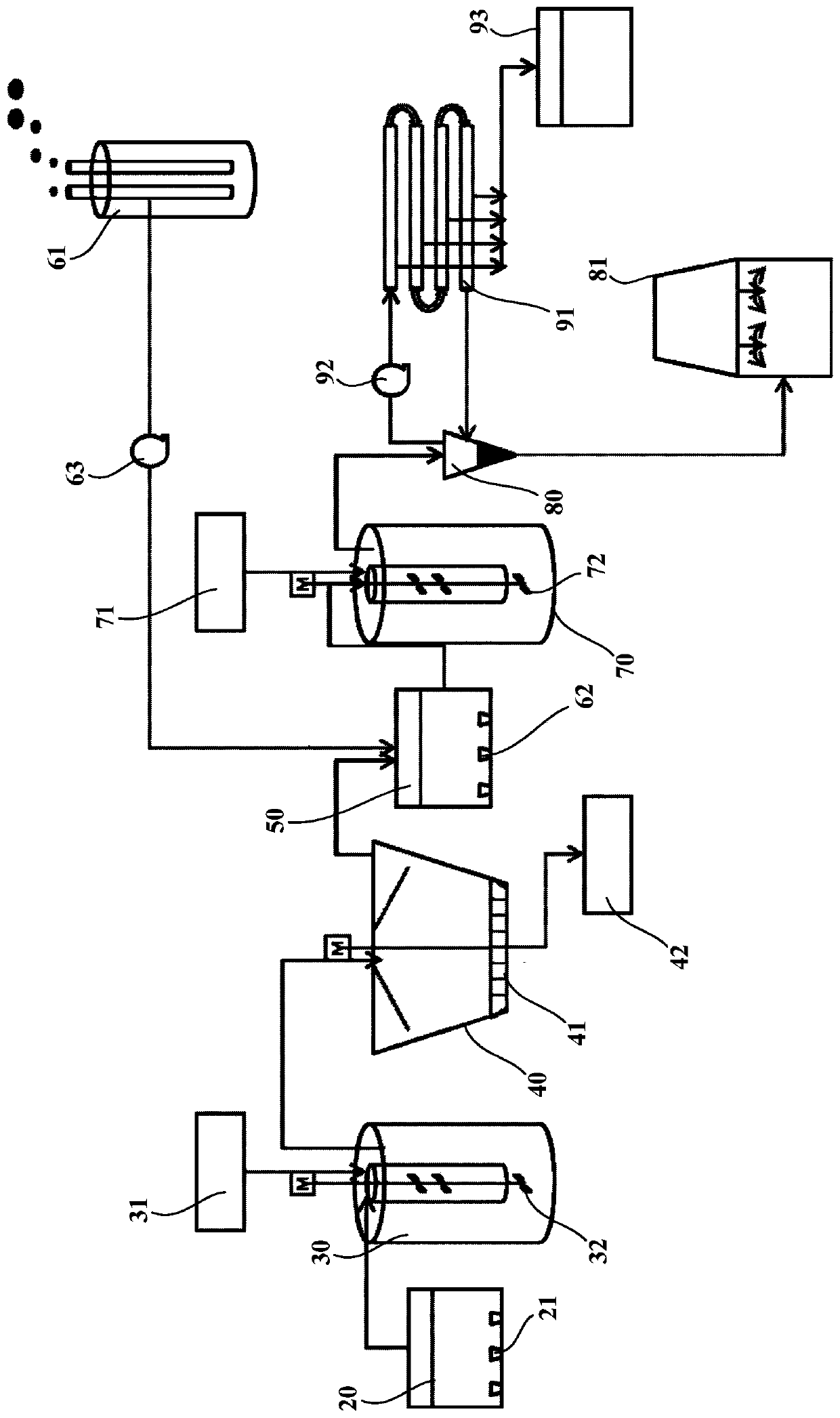

[0045] figure 1 is a schematic structural diagram of a wastewater treatment system according to an embodiment of the present invention. Such as figure 1 As shown, the embodiment of the present invention provides a wastewater treatment system. The wastewater treatment system includes a primary flocculation reaction tank 30, Ca(OH) 2 Dosing system 31, primary clarification tank 40, secondary flue gas reaction tank 50 and flue gas adding device. The primary flocculation reaction tank 30 is configured to receive wastewater. Ca(OH) 2 The dosing system 31 is configured to add Ca(OH) to the primary flocculation reaction tank 30 2. The primary clarification tank 40 communicates with the primary flocculation reaction tank 30 to receive the wastewater in the primary flocculation reaction tank 30 . The secondary flue gas reaction tank 50 communicates with the primary clarifier 40 to receive the waste water in the primary clarifier 40 . The flue gas adding device is configured to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com