Rectifying plate and grooved cleaning machine

A rectifying plate and cleaning machine technology, which is applied to chemical instruments and methods, cleaning methods and appliances, electrical components, etc., can solve the problems that the lower chamber of the tank is difficult to clean, so as to improve the utilization rate of the machine, facilitate cleaning, and save energy. The effect of maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

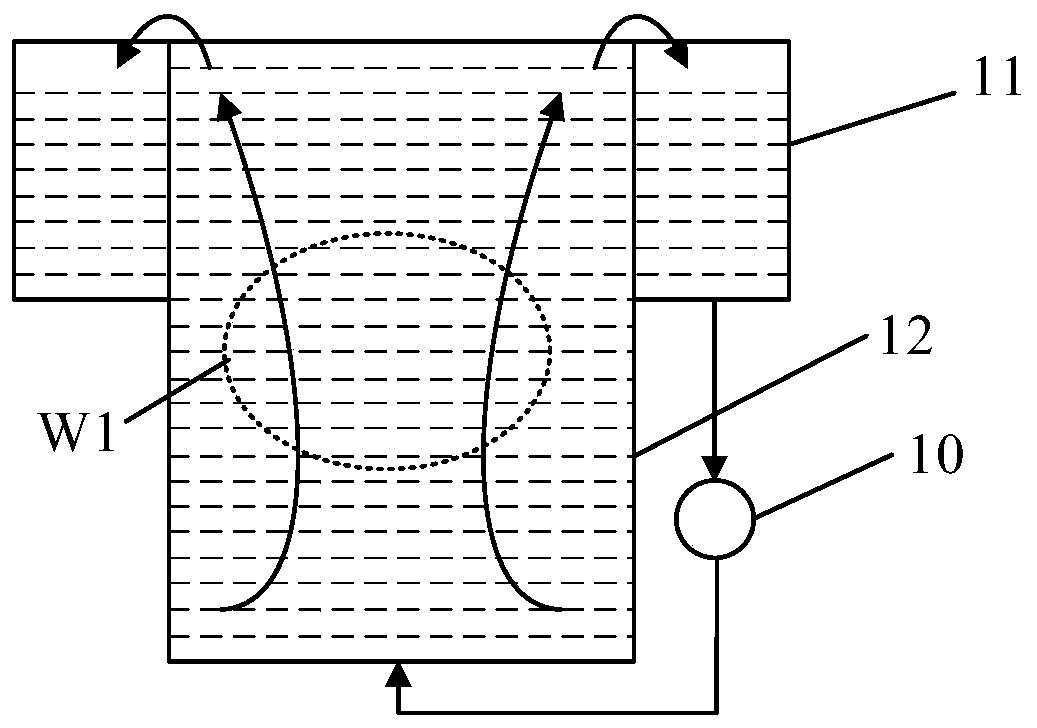

[0031] Such as figure 1 As shown, in a conventional tank cleaning machine, the cleaning liquid is generally circulated between the outer tank 11 and the inner tank 12 by a pump 10 . However, when the cleaning liquid flows in the inner tank, the problem of uneven flow is likely to occur, resulting in poor uniformity of etching and cleaning of the wafer W1.

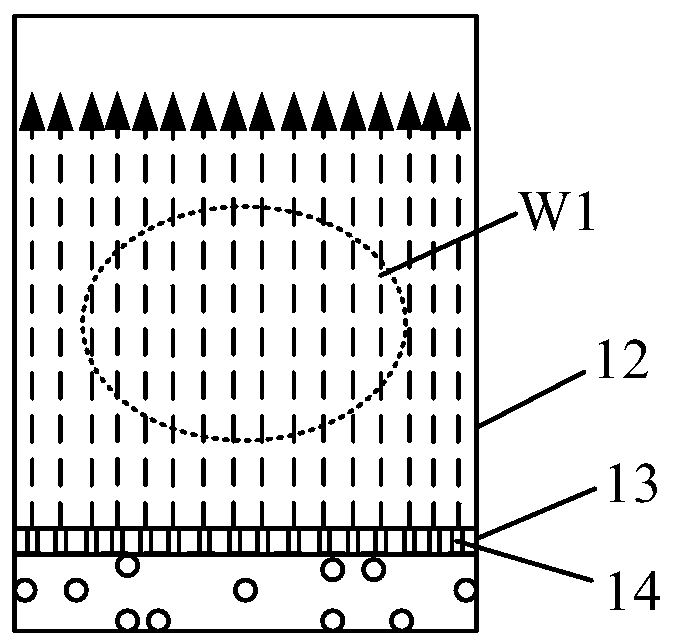

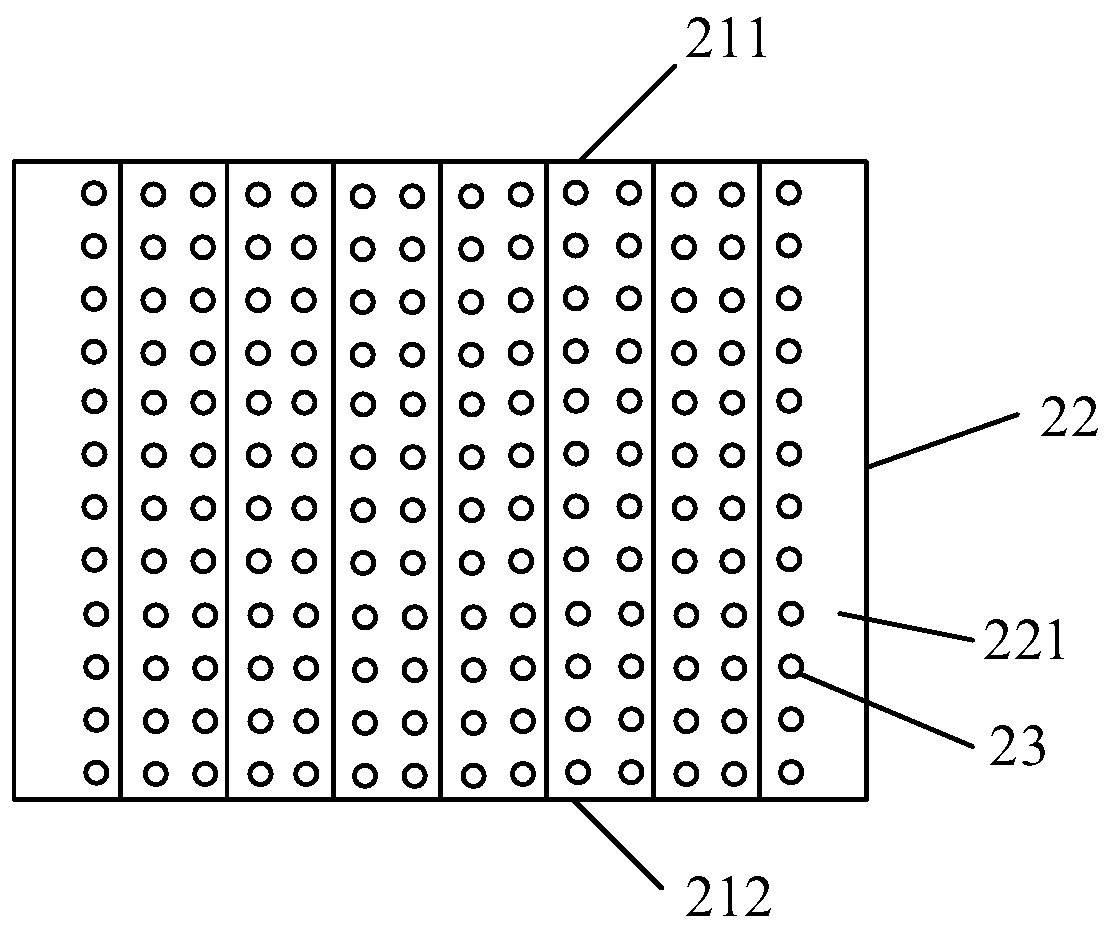

[0032] At present, the way to solve the above-mentioned uneven flow of the cleaning solution is to set a plate-shaped structure with through holes in the inner tank 12, and the wafer W1 is placed on the plate-shaped structure. Such as figure 2 As shown, rectifying plate 13 is set in inner groove 12, and rectifying plate 13 is provided with some through holes 14, and through hole 14 makes the liquid by rectifying plate 13 be shunted into more strands, and the liquid of more strands is to rectifying plate 13 The liquid stored in the upper part has the functions of pushing and stirring, so that the various ions in the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com