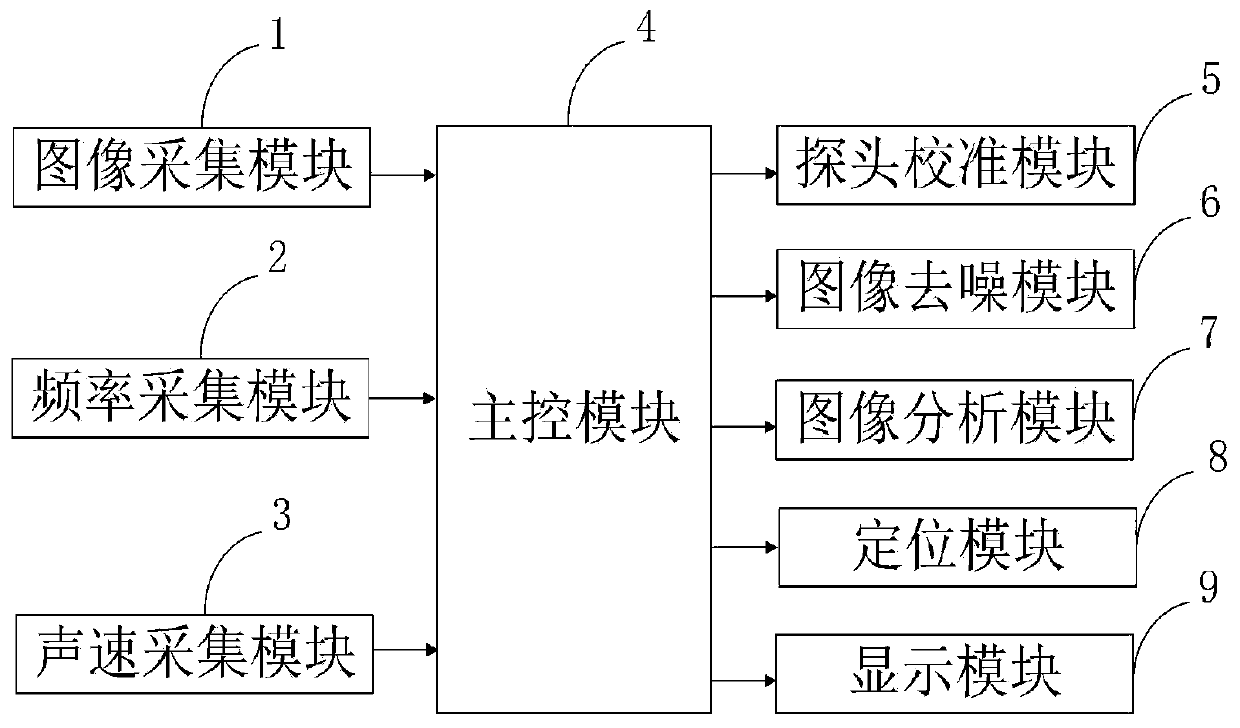

Accurate positioning machine suitable for high-frequency ultrasound probe and control method

An ultrasonic probe and precise positioning technology, which is applied in the fields of ultrasonic/sonic/infrasonic diagnosis, application, and sound wave diagnosis, etc., can solve the problems of large noise in ultrasonic image acquisition, difficulty in meeting measurement requirements, and inaccurate images, so as to achieve accurate results and improve Three-dimensional positioning accuracy, the effect of simplifying the calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

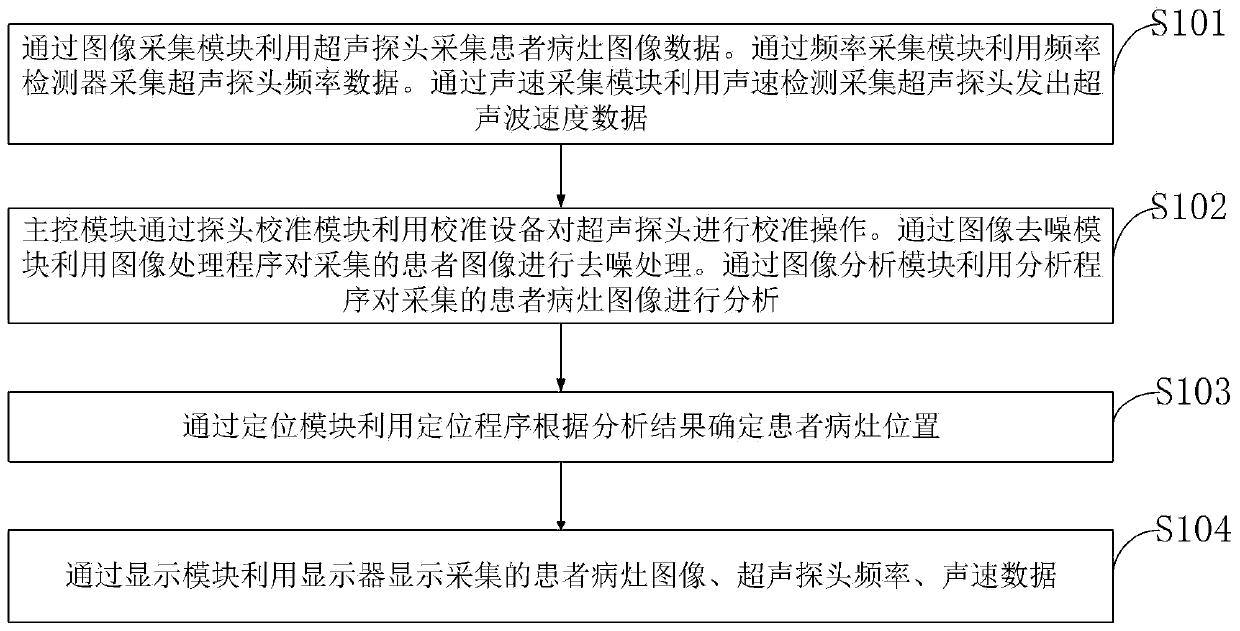

[0071] The calibration method of the probe calibration module 5 provided by the present invention includes:

[0072] 1) Obtaining the blind area of the ultrasonic probe at a preset detection depth by means of detection equipment.

[0073] 2) Place the ultrasonic probe under a three-dimensional magnetic field, and obtain the first imaging image obtained when the ultrasonic probe scans the air, when the acoustic lens of the ultrasonic probe touches the top of the free sensor coated with couplant The obtained second image. Wherein, the color values of the first imaging image and the second imaging image are the same.

[0074] 3) Select any two arcs in the second imaging image as the initial arc and the concentric arc respectively, and calculate the center coordinates, radius and arc of the initial arc and the concentric arc respectively The pixel coordinates on .

[0075] 4) Obtaining the first color difference ratio of the pixel point color value of the starting arc and a...

Embodiment 2

[0080] Image denoising module 6 denoising method provided by the present invention comprises:

[0081] (1) Determine the initial grayscale value of the real image and the initial grayscale value of the speckle image based on the total variation image denoising model of the ultrasonic image through an image processing program.

[0082] (2) Based on the minimization model of the ultrasonic image, iteratively estimate the initial gray value of the real image and the initial gray value of the speckle image respectively, when the estimated gray value of the real image and When the estimated gray value of the speckle image meets the preset convergence condition, the estimated gray value of the real image and the estimated gray value of the speckle image are obtained. A denoised ultrasonic image is generated according to the estimated gray value of the real image.

[0083] The minimization model based on the ultrasonic image provided by the present invention performs iterative estim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com