Cathode plate, bipolar plate, fuel cell stack, power assembly and transportation tool

A fuel cell and cathode plate technology, which is applied to fuel cells, fuel cell groups, circuits, etc., can solve the problems of increasing mass transfer capacity, large flow pressure drop, and increasing flow resistance, so as to improve performance, avoid increase, and improve transmission. The effect of qualitative abilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

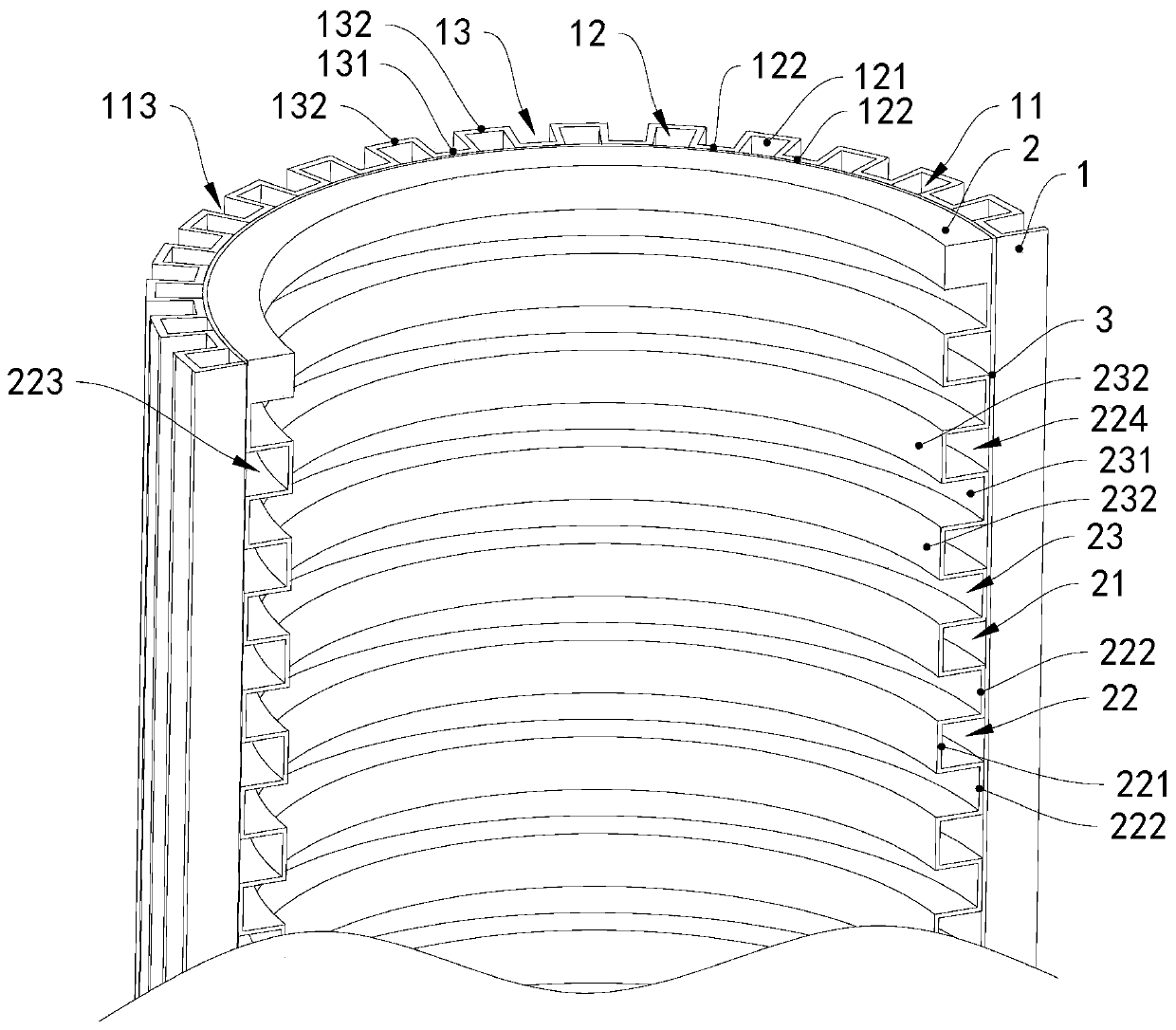

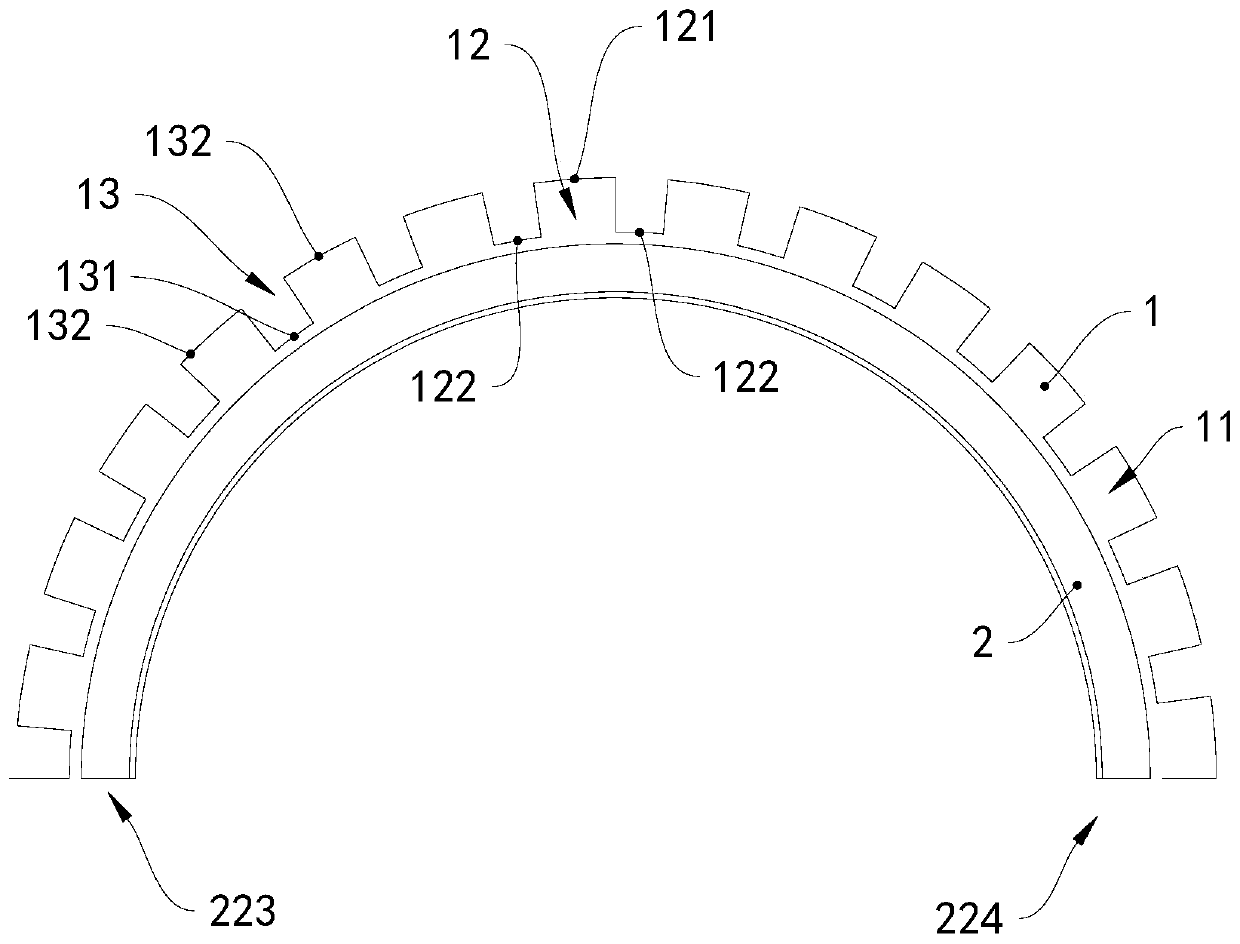

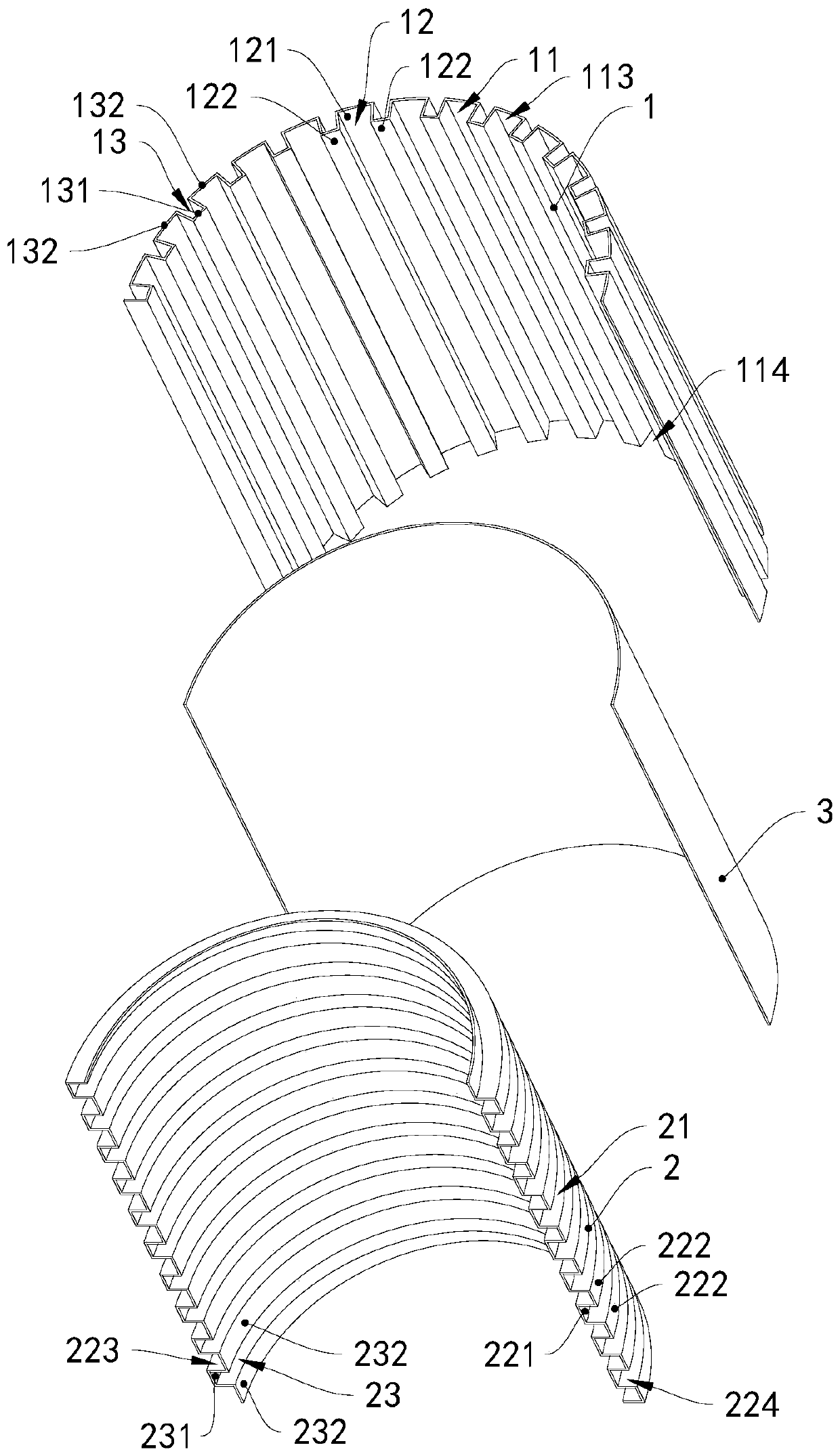

[0044] see Figure 1 to Figure 4 , the fuel cell of this embodiment includes a membrane electrode 3 and a bipolar plate, the bipolar plate includes an anode plate 1 and a cathode plate 2, the membrane electrode 3 is located between the anode plate 1 and the cathode plate 2, and the anode plate 1, the membrane electrode 3 It is arranged in close contact with the cathode plate 2. Both the cathode plate 2 and the anode plate 1 are made of metal materials, and both the cathode plate 2 and the anode plate 1 are formed by stamping.

[0045]The cathode plate 2 is an arc whose central angle is a flat angle, and the axial direction of the cathode plate 2 extends along the vertical direction. The cathode plate 2 is provided with a cathode gas flow field 21, and the cathode gas flow field 21 includes a cathode air intake main channel (not shown Shown), the cathode gas outlet main channel (not shown) and a plurality of cathode gas sub-channels 22, the first ends of the plurality of catho...

no. 4 example

[0064] As the description of the fourth embodiment of the cathode plate and bipolar plate of the fuel cell of the present invention, only the differences from the first embodiment of the cathode plate and bipolar plate of the fuel cell described above will be described below.

[0065] see Figure 7 , the cathode plate 7 and the anode plate 8 are arcs whose central angle is the peripheral angle, that is, circular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com