Electromagnetic relay with armature single-side stop

An electromagnetic relay and armature technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of reducing the strength of the protruding part, easy to break, and the protruding part is broken, so as to ensure the contact pressure and achieve the balance limit. bit, the effect of ensuring contact reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

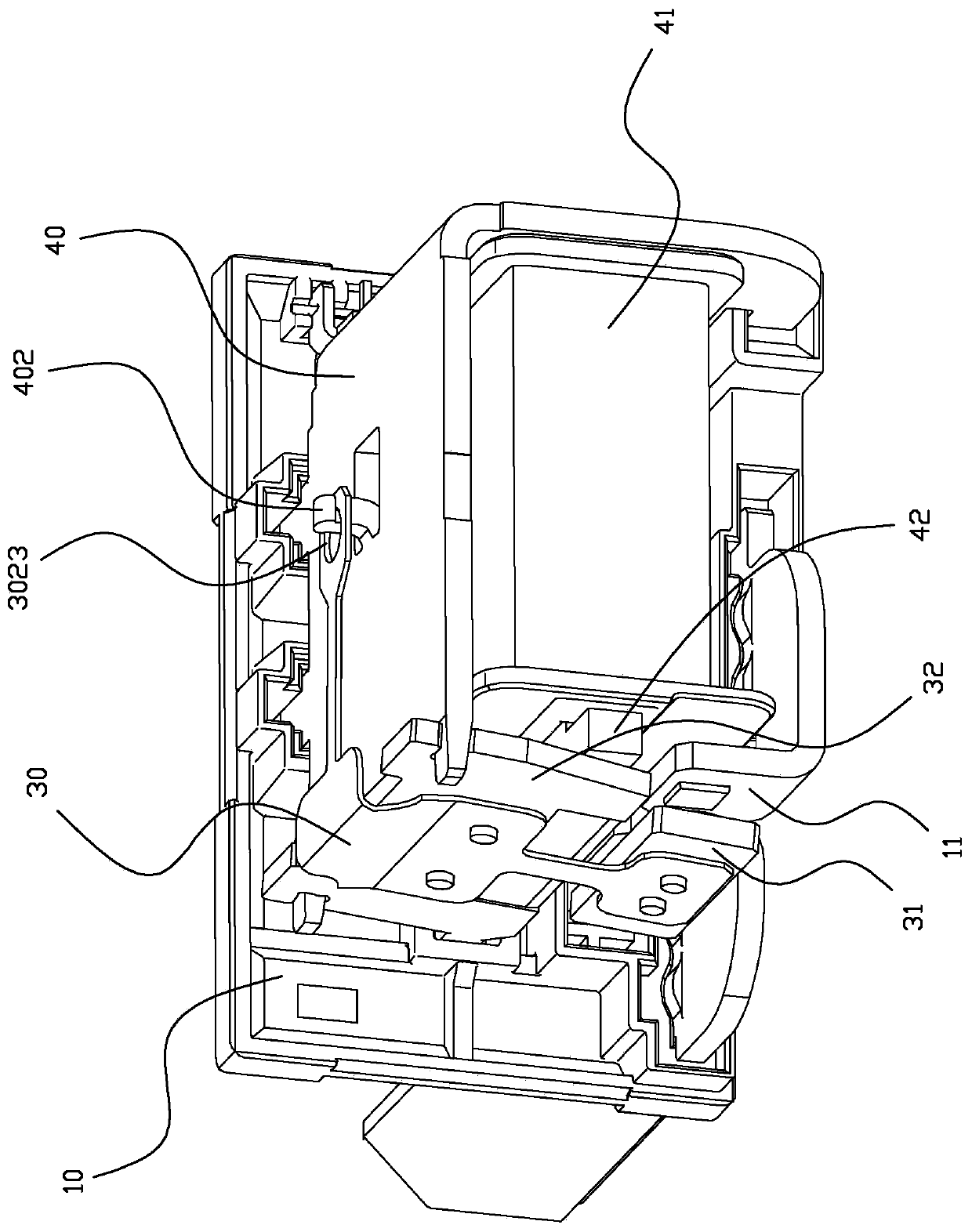

[0044] In order to solve the shortcomings of the prior art, such as the space occupied by the protruding part of the base, the strength, and the poor balance and limit effect, the present invention provides an electromagnetic relay with a single-side stop for the armature, with a simpler one-side stop structure , cooperate with the moving spring to form a balance limit system to realize the balance limit of the armature.

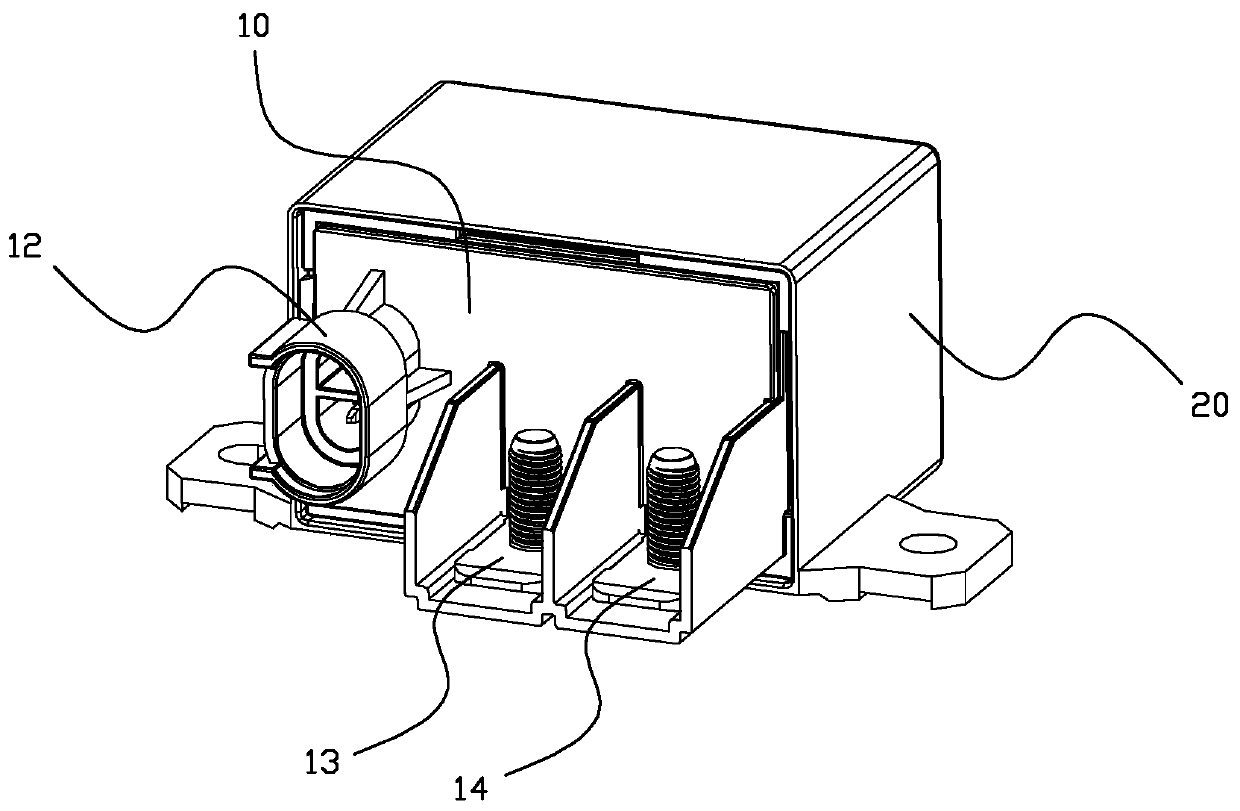

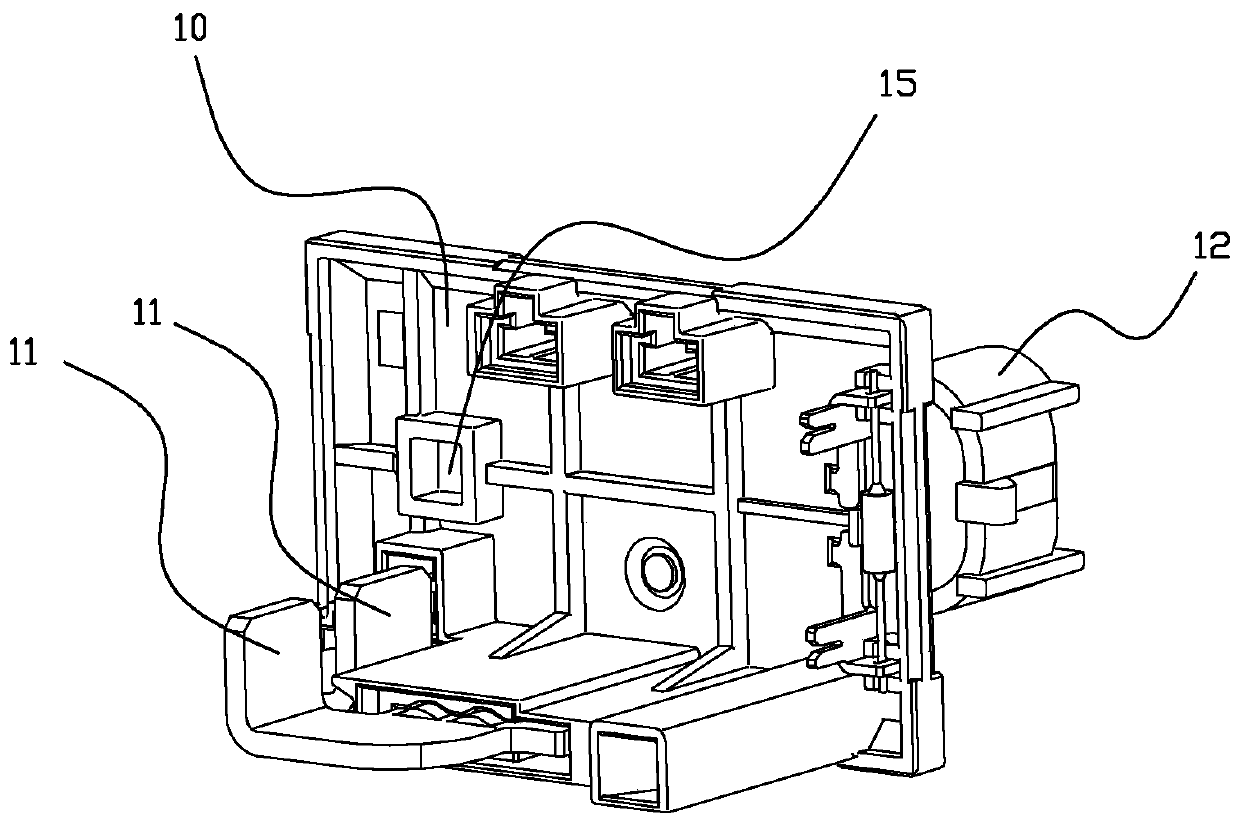

[0045] Such as figure 1 , image 3As shown, the electromagnetic relay with unilateral stop of the armature 32 according to the present invention includes a base 10, a cover 20, a magnetic circuit assembly, and a reset assembly. The inner side of the base 10 is provided with a static contact mechanism 11, and the outer side of the base 10 is provided with There are outer wire harness interface 12, outgoing line joint 13, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com