Self-adaptive quality forecasting method based on incremental support vector regression

A support vector regression and self-adaptive technology, applied in the direction of comprehensive factory control, instrumentation, comprehensive factory control, etc., can solve the problem that the model cannot guarantee long-term application, and achieve the effect of improving update efficiency and reducing update frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

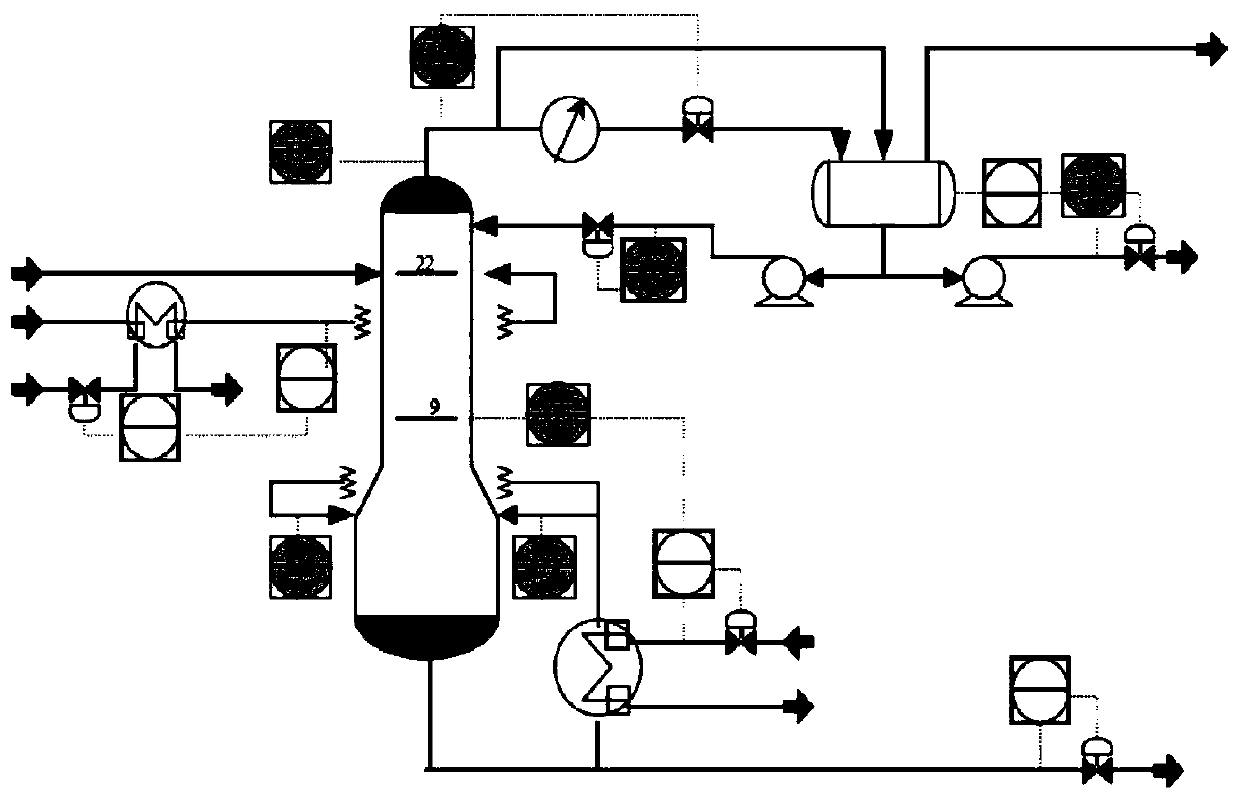

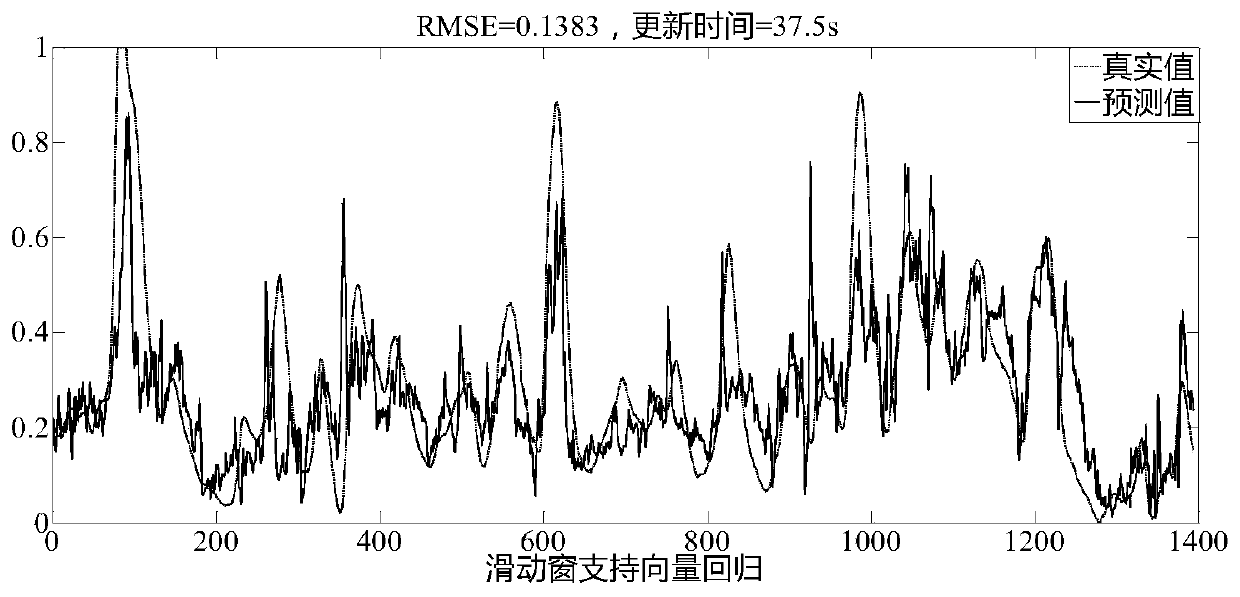

[0052] The following is a specific example of a debutanizer to illustrate the performance of the incremental support vector regression model. The debutanizer is a commonly used standard industrial process platform for verification of soft-sensing modeling algorithms. Debutanizer is one of the devices in the refining process, the flow chart is as follows figure 2 As shown, the purpose of this device is to remove propane and butane from naphtha gas. Butane content at the bottom of the tower is a very important key indicator. In order to improve the control quality of the butane tower A soft-sensing model is established for the bottom butane content.

[0053] Table 1 shows the 7 auxiliary variables selected for the key quality variable butane content, and describes certain variables, which are tower top temperature, tower top pressure, reflux flow, next-stage flow, and sensitive plate Temperature, bottom temperature and bottom pressure.

[0054] Table 1: Input variable description ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com