Multi-functional oil supplementary valve for diaphragm pump

A multi-functional, diaphragm pump technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve problems such as insufficient oil supply, oil supply failure, slide valve jamming, etc., and achieve good work reliability , The effect of reducing the requirements of oil products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

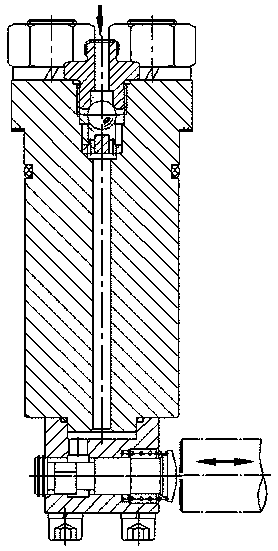

Image

Examples

Embodiment Construction

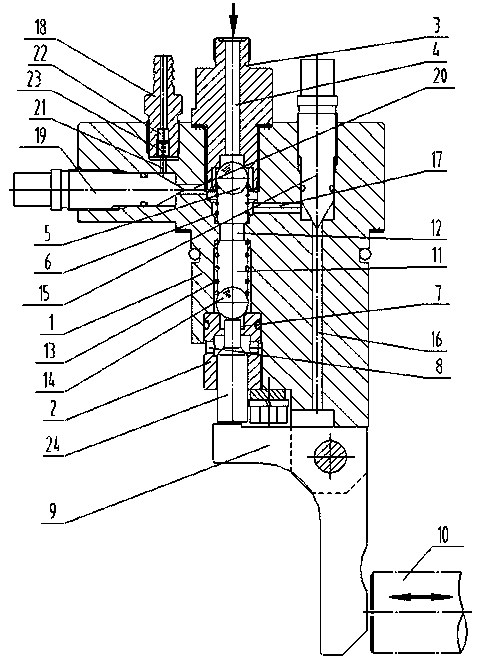

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] see figure 2 , it can be seen from the figure that the multifunctional oil replenishment valve for diaphragm pump of the present invention includes a valve body 1, a valve seat 2 and an oil inlet joint 3, and the oil inlet joint 3 is provided with an oil inlet hole 4 through which both ends are connected. The oil joint 3 is installed above the valve body 1 through the vertical channel on the valve body, and the valve ball B5 and the spring B6 are arranged in the channel below the oil inlet joint 3, and the spring B6 provides the upward force of the valve ball B5. The thrust makes the valve ball B 5 close the oil outlet of the oil inlet joint, and the oil outlet of the oil inlet joint can be opened under the oil inlet pressure. The valve body 1 is provided with a valve seat stepped hole with a large hole facing downward, and the valve seat 2 is installed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com