Solid waste screening and separating treatment system

A technology for separation and treatment of solid waste, applied in the field of solid waste screening and separation treatment systems, can solve problems such as fine classification, and achieve the effects of flexible use, easy collection and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

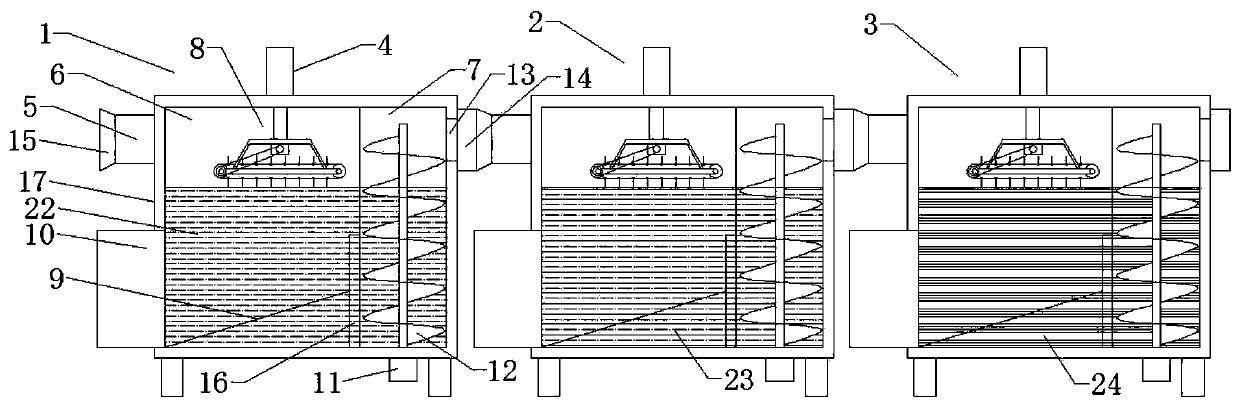

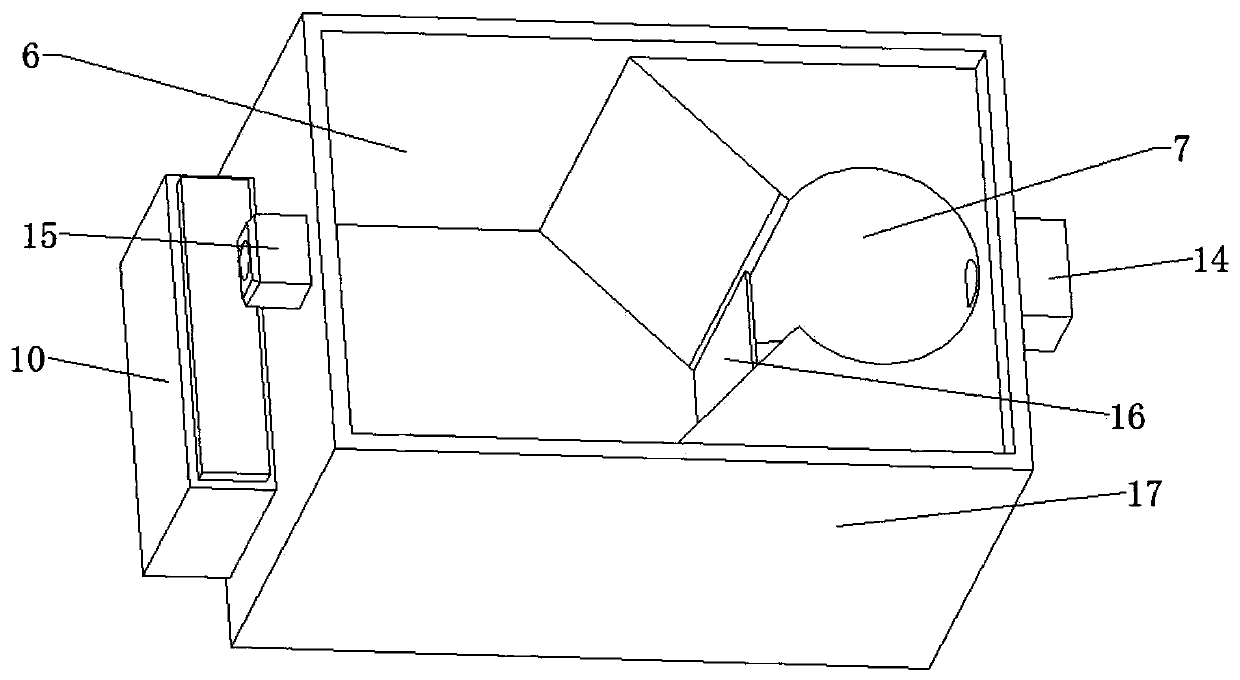

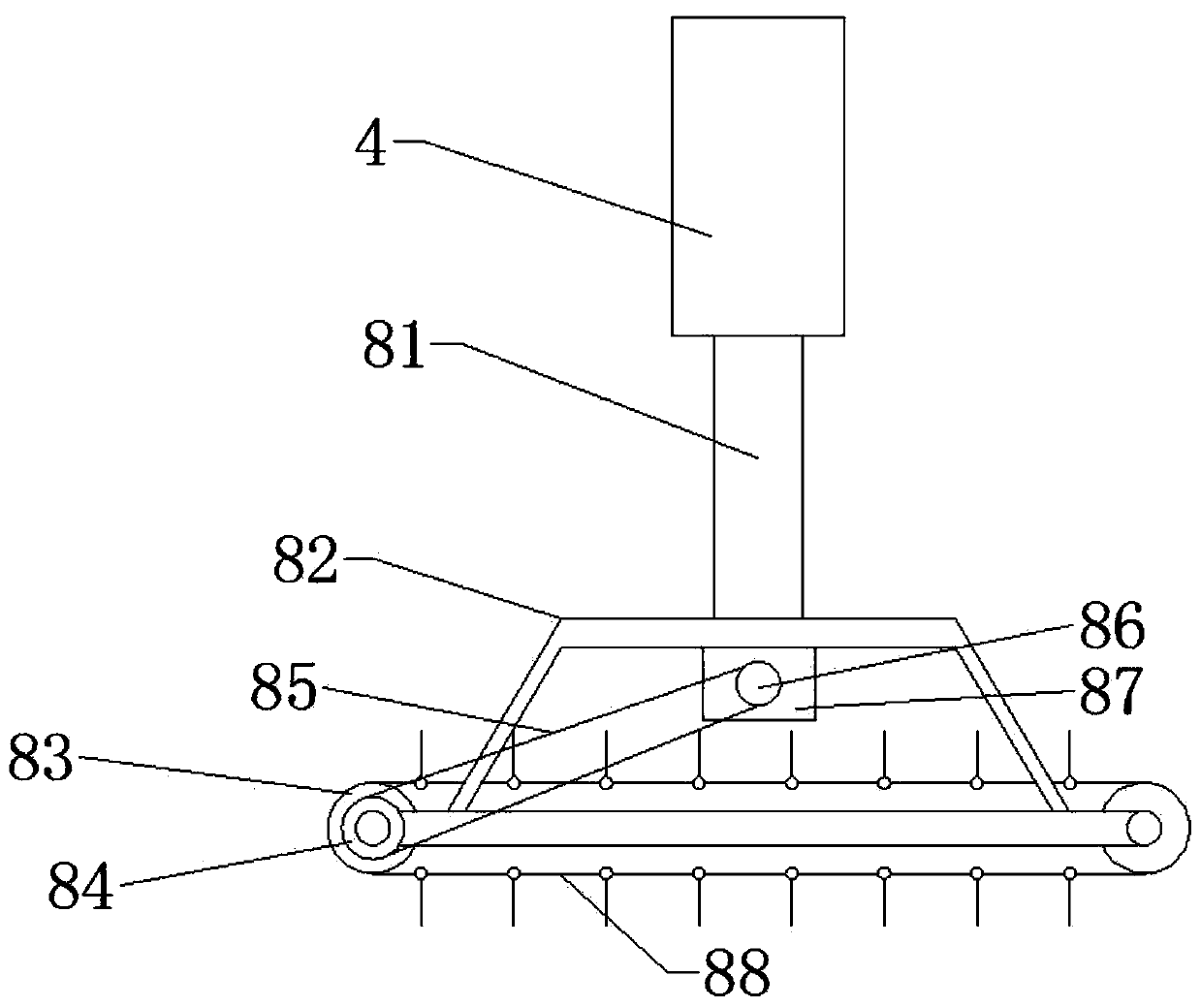

[0021] Please refer to the figure, in the embodiment of the present invention, a solid waste screening and separation treatment system includes a first separation box 1, a second separation box 2, a third separation box 3, a collection box 10, a lifting motor 11 and a spiral lifting blade 12 ; The structure of the first separation box 1, the second separation box 2, and the third separation box 3 is the same, and they are connected in sequence, so that solid waste can move inside, and the first separation box 1, the second separation box 2, the second separation box The first separation liquid 22, the second separation liquid 23, and the third separation liquid 24 are correspondingly filled in the three separation boxes 3, and the density of the first separation liquid 22, the second separation liquid 23, and the third separation liquid 24 gradually decreases, and the density of the third separation liquid 24 decreases gradually. The density of a separation liquid 22 is the lar...

Embodiment 2

[0027] On the basis of Example 1, several separation boxes with the same structure as the first separation box 1 can be provided, and they are sequentially connected through the feed port 5 and the discharge port 13, and the internal packing density gradually decreases. The amount of liquid can be selected according to the number of solid wastes to be separated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com