Asymmetric structure paper-based graphite intelligent film integrating sensing and driving, preparation method and application

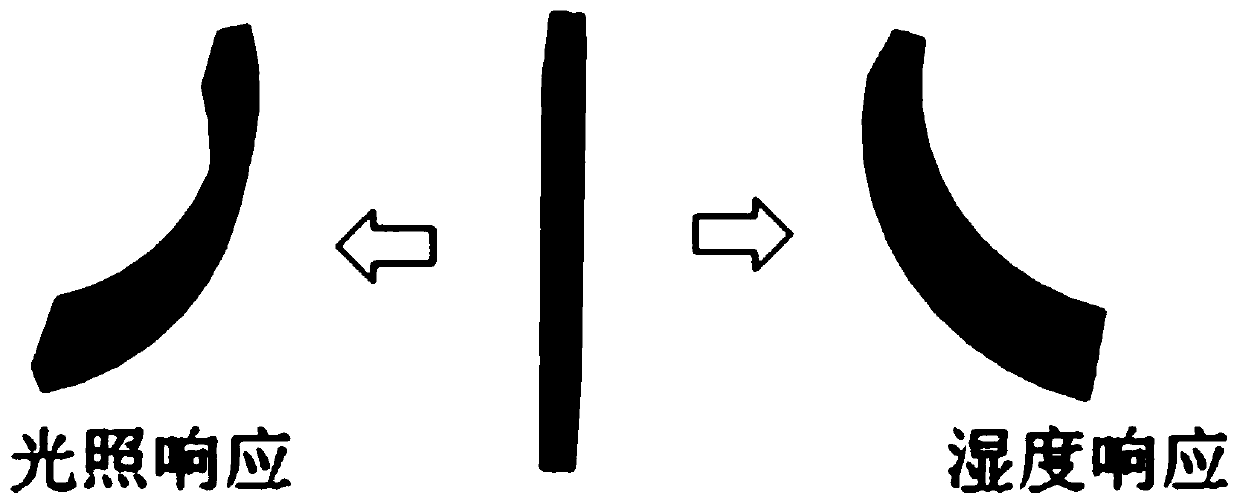

A technology of graphene film and asymmetric structure, which is applied in the fields of application, sensor, medical science, etc., and achieves the effect of good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

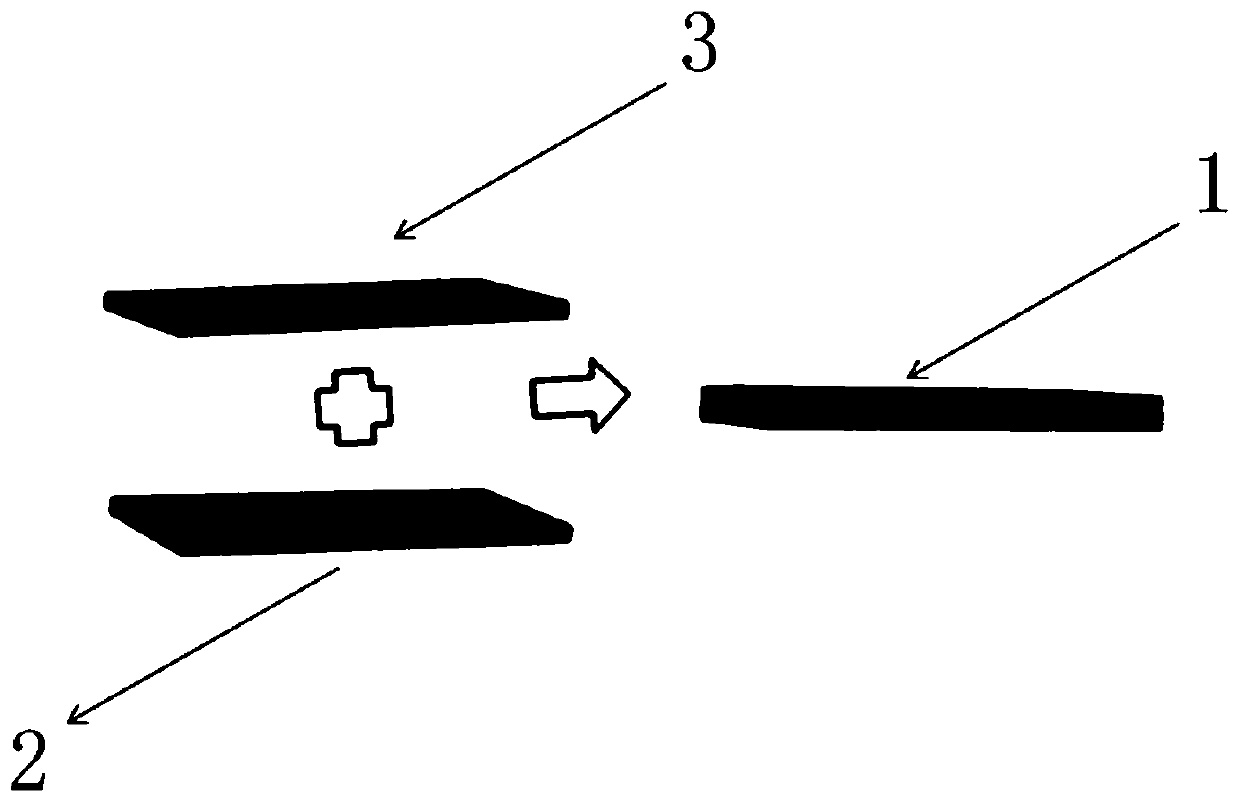

[0030] A preparation method when a paper-based graphene film is applied to a flexible driver, comprising the following steps:

[0031] First, commercial printing paper, paper, was cut into rectangles with a size of 75 mm × 25 mm (length × width), and immersed in a Petri dish containing graphene oxide aqueous solution (1.5 mg / ml, 40 mL) for 5 min. After impregnation, it was placed on a glass substrate and dried by heating at 40 °C for 1 h. Then the dried paper was repeatedly immersed in the graphene oxide solution to repeat the above drying process, and after 15 dips, a paper-based graphene oxide film with an asymmetric structure was obtained.

[0032] Then, the film was further placed in a hydroiodic acid (HI) solution for 1.5 h in the dark, then washed with ethanol and water in sequence, and then placed on a heating platform at 30°C for 1 h to obtain an asymmetric paper-based graphene oxide film.

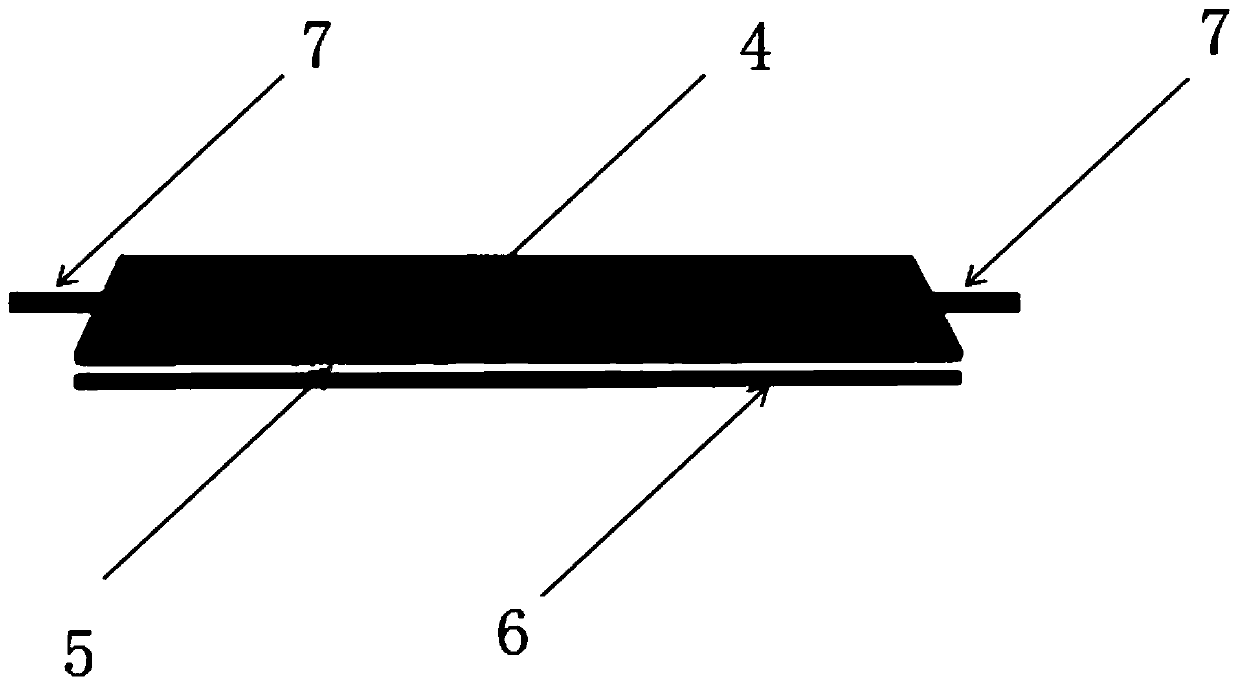

[0033] Finally, it is bonded with an adhesive polyethylene film to prepare a...

Embodiment 2

[0042] A preparation method when a paper-based graphene film is applied to a flexible sensor, comprising the following steps:

[0043]First, commercial printing paper, paper, was cut into a rectangle with a size of 75 mm × 25 mm (length × width), and immersed in a Petri dish containing an aqueous solution of graphene oxide (1 mg / ml, 40 mL) for 5 min. After impregnation, it was placed on a glass substrate and dried by heating at 40 °C for 1 h. Then the dried paper was repeatedly dipped into the graphene oxide solution to repeat the above drying process, and a paper-based graphene oxide film with an asymmetric structure was obtained after dipping 35 times.

[0044] Then, the film was further placed in hydroiodic acid (HI) solution for 1.5 h in the dark, then washed with ethanol and water in sequence, and then placed on a heating platform at 50 ° C for 1 h to obtain an asymmetric paper-based graphene oxide film.

[0045] Then, use conductive silver glue to bond the conductive c...

Embodiment 3

[0050] A method for preparing a paper-based graphene film integrating sensing and driving, comprising the following steps:

[0051] First, commercial printing paper, paper, was cut into rectangles with a size of 75 mm × 25 mm (length × width), and immersed in a Petri dish containing an aqueous solution of graphene oxide (2 mg / ml, 40 mL) for 5 min. After impregnation, it was placed on a glass substrate and dried by heating at 40 °C for 1 h. Then the dried paper was repeatedly dipped into the graphene oxide solution to repeat the above drying process, and a paper-based graphene oxide film with an asymmetric structure was obtained after dipping 25 times.

[0052] Then, the film was further placed in hydroiodic acid (HI) solution for 1.5 h in the dark, then washed with ethanol and water in sequence, and then placed on a heating platform at 40 ° C for 1 h to obtain an asymmetric paper-based graphene oxide film.

[0053] Next, use conductive silver glue to bond the conductive copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com