An asymmetric structure paper-based graphene smart film integrating sensing and driving, preparation method and application

A graphene film and graphene technology, applied in the fields of applications, sensors, medical science, etc., to achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method when a paper-based graphene film is applied to a flexible actuator, comprising the following steps:

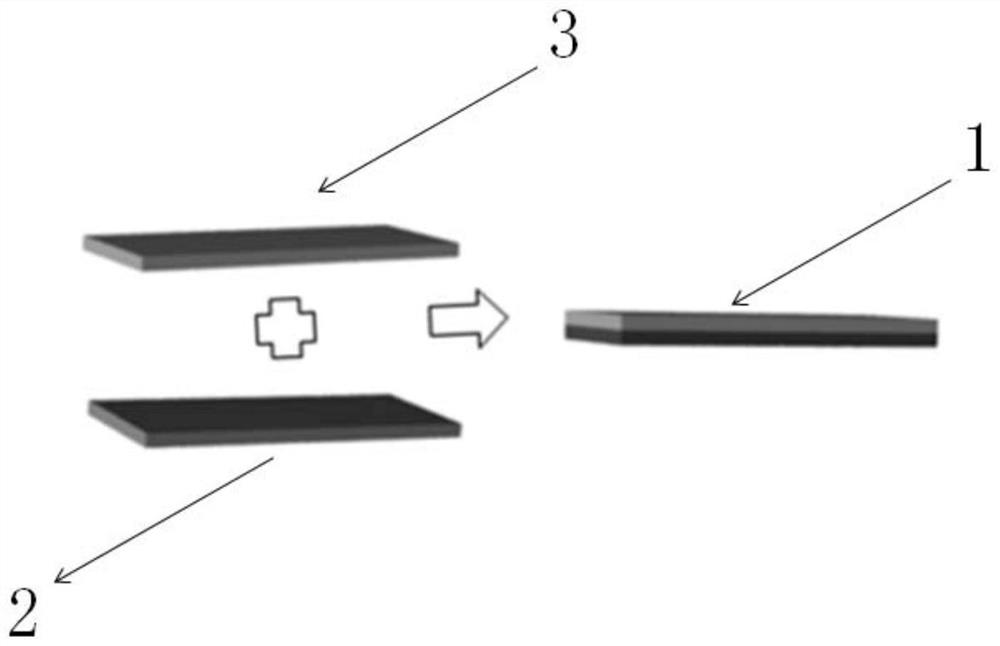

[0031] First, commercial printing paper, paper, was cut into rectangles with dimensions of 75 mm × 25 mm (length × width) and immersed in a petri dish containing an aqueous solution of graphene oxide (1.5 mg / ml, 40 mL) for 5 min. After dipping, it was placed on a glass substrate and dried by heating at 40°C for 1 h. Then, the dried paper is repeatedly dipped into the graphene oxide solution to repeat the above drying process, and after 15 times of dipping, a paper-based graphene oxide film with an asymmetric structure is obtained.

[0032] Then, the film was further put into a hydroiodic acid (HI) solution for 1.5 h in the dark, washed with ethanol and water in turn, and then placed on a heating platform at 30 °C for 1 h to obtain asymmetric paper-based graphene oxide film.

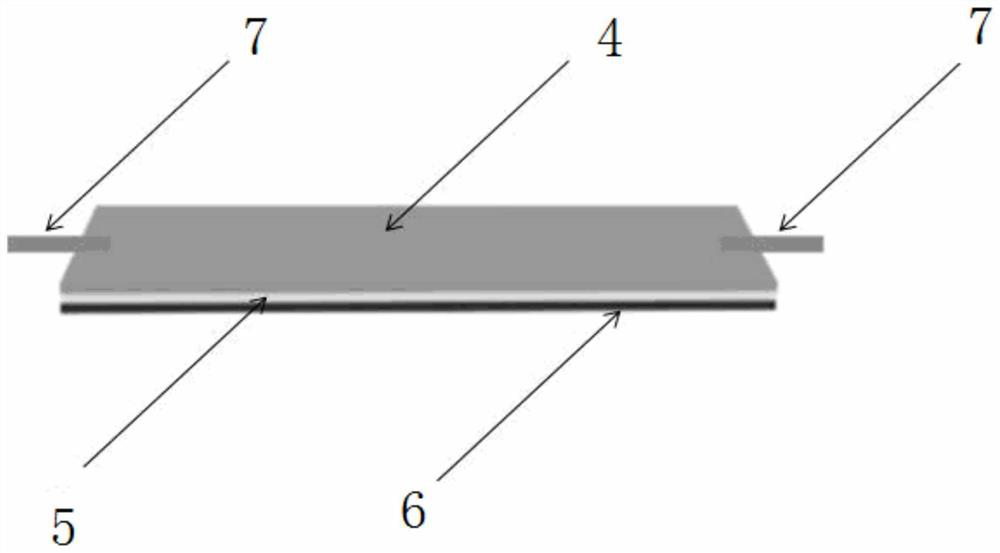

[0033] Finally, it is bonded with an adhesive polyethylene film to prepa...

Embodiment 2

[0042] A preparation method when a paper-based graphene film is applied to a flexible sensor, comprising the following steps:

[0043]First, commercial printing paper was cut into rectangles with dimensions of 75 mm × 25 mm (length × width) and immersed in a petri dish containing an aqueous solution of graphene oxide (1 mg / ml, 40 mL) for 5 min. After dipping, it was placed on a glass substrate and dried by heating at 40°C for 1 h. Then, the dried paper is repeatedly dipped into the graphene oxide solution to repeat the above drying process, and after dipping for 35 times, a paper-based graphene oxide film with an asymmetric structure is obtained.

[0044] Then, the film was further put into a hydroiodic acid (HI) solution for 1.5 h in the dark, washed with ethanol and water in turn, and then placed on a heating platform at 50 °C for 1 h to obtain asymmetric paper-based graphene oxide film.

[0045] Next, the conductive copper foil is bonded to the upper surface of the paper-...

Embodiment 3

[0050] A preparation method of a paper-based graphene film integrating sensing and driving, comprising the following steps:

[0051] First, commercial printing paper, paper, was cut into rectangles with dimensions of 75 mm × 25 mm (length × width) and immersed in a petri dish containing an aqueous solution of graphene oxide (2 mg / ml, 40 mL) for 5 min. After dipping, it was placed on a glass substrate and dried by heating at 40°C for 1 h. Then, the dried paper is repeatedly dipped into the graphene oxide solution to repeat the above drying process, and after 25 times of dipping, a paper-based graphene oxide film with an asymmetric structure is obtained.

[0052] Then, the film was further put into a hydroiodic acid (HI) solution for 1.5 h in the dark, washed with ethanol and water in turn, and then placed on a heating platform at 40 °C for 1 h to obtain asymmetric paper-based graphene oxide film.

[0053] Next, the conductive copper foil is bonded to the upper surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com