Door for cleaning machine and assembly method of door

A cleaning machine and door body technology, applied in the field of kitchen utensils, can solve the problems of affecting the sealing effect, the separation of the door sealing strip, the falling off of the door sealing strip, etc., and achieve the effect of good sealing effect, stable door body structure, and easy positioning and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

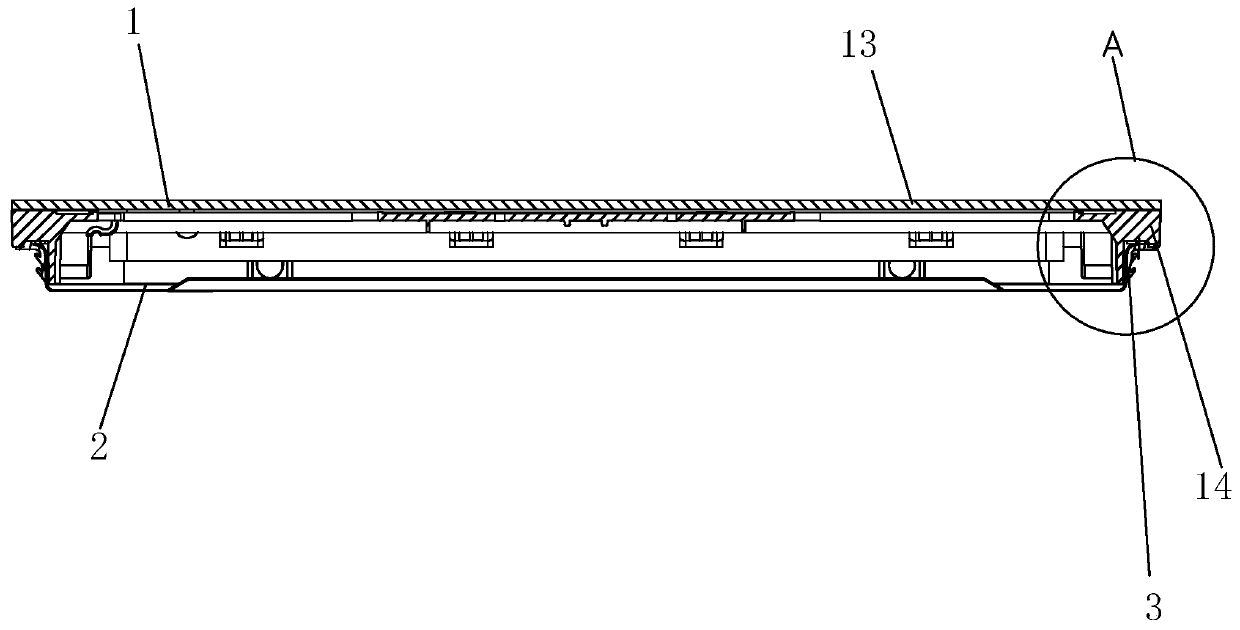

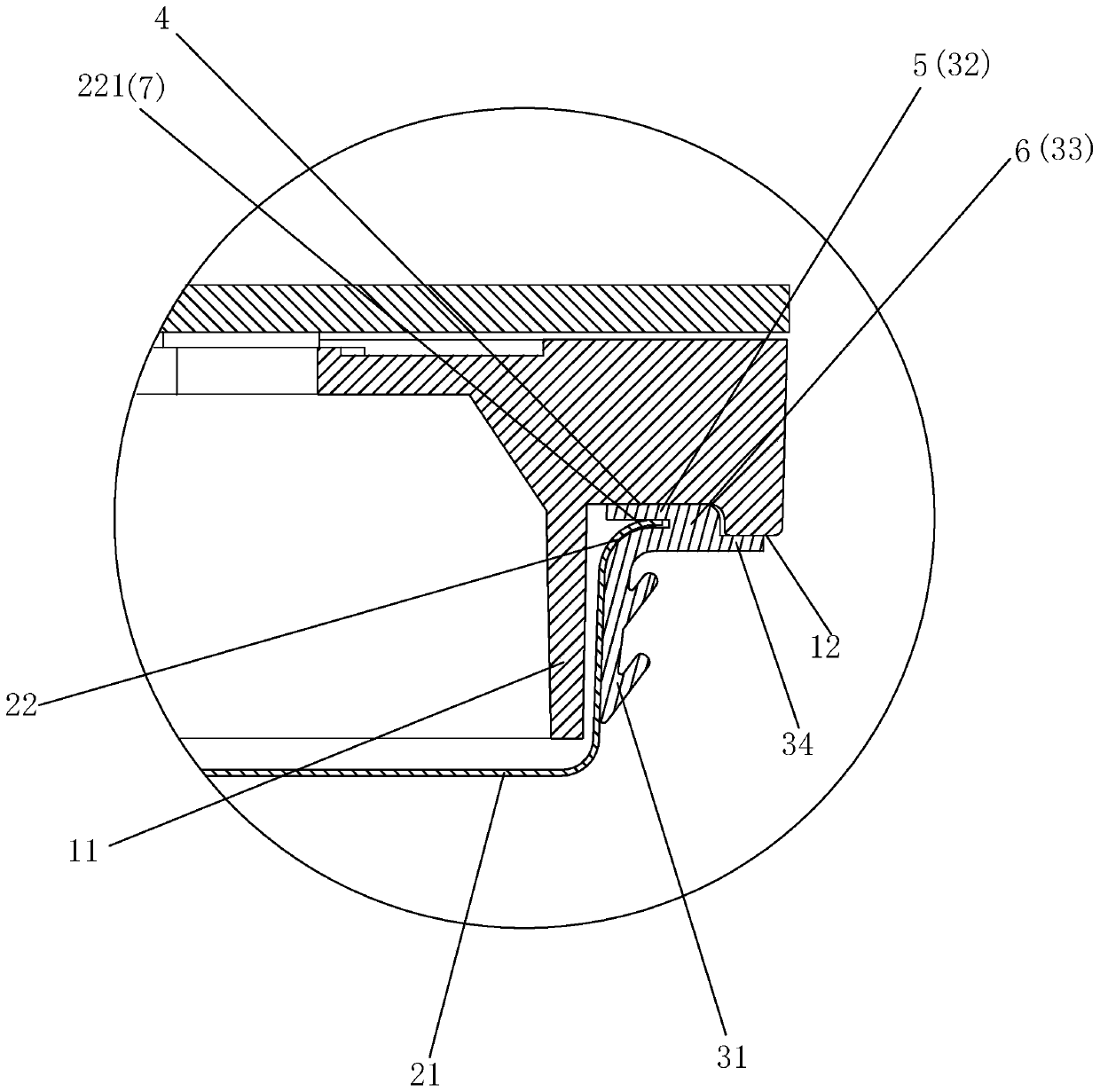

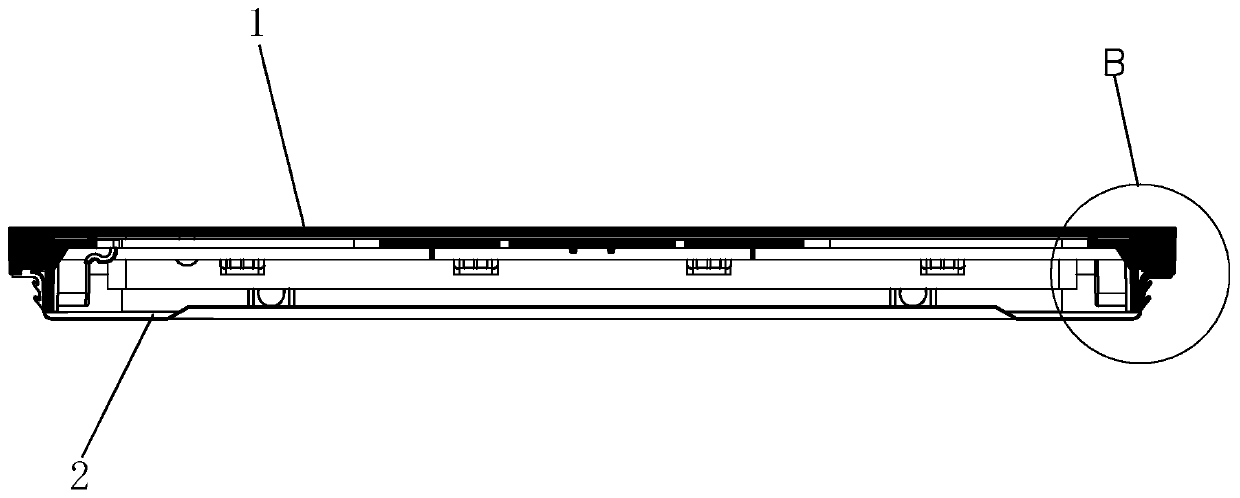

[0021] See attached Figure 1~2 For the first preferred embodiment of the door body of the cleaning machine provided by the present invention, the door body of the cleaning machine provided by the present invention includes a panel 1 and a door decoration cover 2 that is covered with the panel 1, and also includes a cover for sealing the panel 1 and the door sealing strip 3 of the door decoration cover 2, the panel 1 has a decorative inner frame 11, and a clamping groove 4 is formed between the decorative inner frame 11 and the outer periphery of the panel 1, and the door decoration cover 2 has a The door decoration cover body 21 outside the frame 11, the decoration cover outer edge 22 extending outward from the door decoration cover body 21 toward the door decoration cover body 21, the decoration cover outer edge 22 corresponds to the clip groove 4, and the decoration cover outer edge 22 has One facing the inner surface 221 of the panel 1, the first sealing groove 5 is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com