A Layout Optimization Method for Video Surveillance in Chemical Plant Area

A technology for video surveillance and layout optimization, applied in TV, CCTV systems, instruments, etc., can solve problems such as unreasonable layout of video surveillance in chemical plant areas, and achieve the effect of low cost and strong monitoring ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

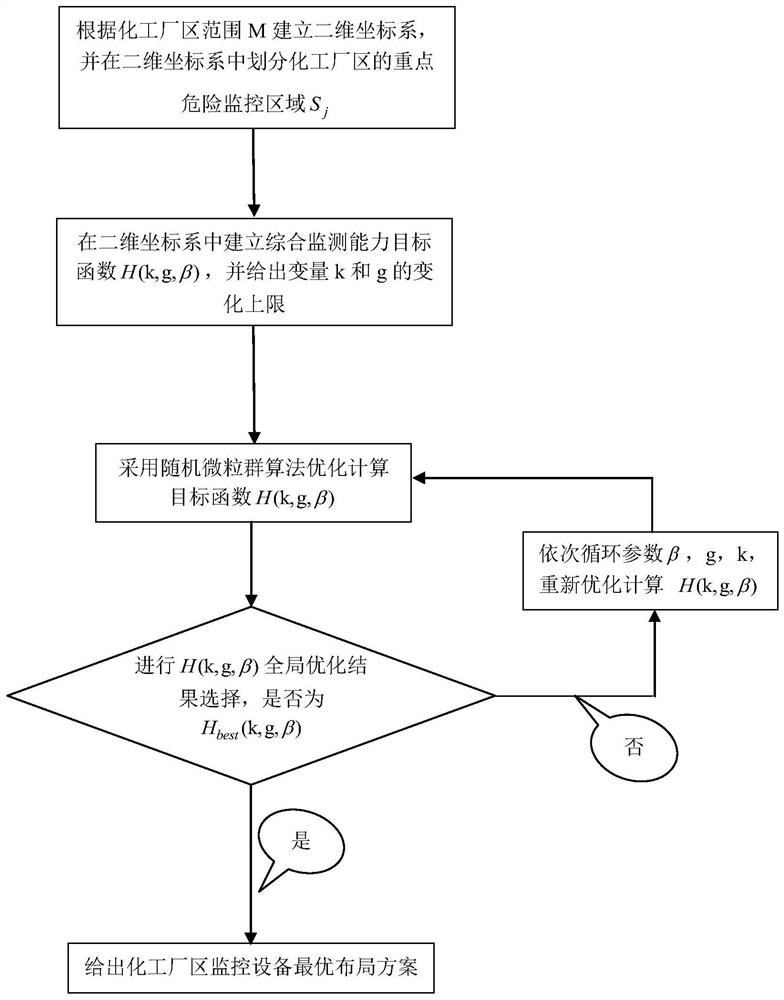

[0041] A layout optimization method for video surveillance in a chemical factory area, comprising the following steps:

[0042] Step 1: Set the operating area of the chemical plant area as M, and on this basis, divide grids with an interval of N along the latitude and longitude directions to form a two-dimensional coordinate system of the chemical plant area. N is a constant and is determined according to the actual situation of the plant area;

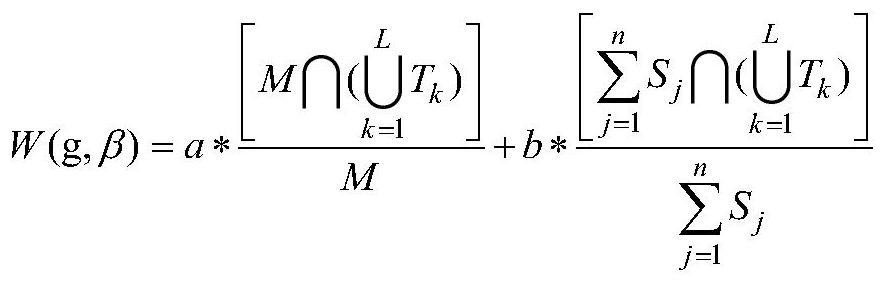

[0043] Step 2: Divide the major dangerous operating points in the chemical plant area in the two-dimensional coordinate system of the chemical plant area, set as S j , where, 0

[0044] Step 3: The video surveillance equipment is T k , video surveillance equipment T k The monitoring area is expressed in a two-dimensiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com